At HILPCB, we manufacture a comprehensive range of high-speed PCBs—from standard digital boards to advanced differential signaling solutions—serving industries where signal integrity isn't negotiable. In high-speed differential systems, one factor can make or break performance: 100-ohm impedance control.

Picture this: a cutting-edge DDR5 memory system passes every simulation. Premium components, flawless routing, meticulous timing analysis. But once assembled, it fails—data corruption appears, eye diagrams collapse, and the memory interface becomes unreliable.

More often than not, the root cause isn't the controller or the memory—it's uncontrolled differential impedance.

Understanding the Invisible Challenge

At multi-gigabit data rates, differential pairs behave as coupled transmission lines with complex electromagnetic interactions. Any deviation from 100-ohm differential impedance introduces signal reflections, creates common-mode noise, and degrades timing margins. These effects corrupt data integrity, increase bit error rates, and compromise system reliability.

The precision requirement is extremely demanding. A mismatch of just 5-10 ohms can consume critical timing budgets, create inter-symbol interference, and disrupt phase relationships in high-speed differential systems. For applications such as DDR5 memory, USB 3.2, or 10G Ethernet, precise 100-ohm differential control is fundamental to achieving reliable data transmission.

High-Speed Digital: Racing Against Physics

DDR5 memory interfaces represent the ultimate challenge in 100-ohm differential impedance control. With data rates reaching 6400 MT/s, each bit transition occurs within 150 picoseconds. At these speeds, a 10% impedance mismatch can consume 40% of the timing margin through reflections and skew.

The complexity multiplies when considering that modern memory channels route through multiple PCB layers, requiring controlled impedance via transitions. Each layer change introduces potential discontinuities that must be managed through precise via design, back-drilling techniques, and sometimes advanced HDI microvias.

Manufacturing Excellence: From Theory to Reality

The HILPCB Approach to 100-Ohm Differential Control

At HILPCB, we've developed a systematic methodology that transforms 100-ohm differential requirements from design constraints into manufacturing specifications. This process begins with electromagnetic simulation and continues through production validation.

Pre-Production Simulation and Verification

Our engineering team employs 3D electromagnetic simulation to predict differential impedance behavior across the complete stackup. We model trace coupling effects, reference plane proximity, and via transition impacts to ensure 100-ohm accuracy before fabrication begins.

One critical factor often overlooked is the glass weave effect in FR4 PCB materials. The periodic glass fiber structure creates localized dielectric constant variations that can cause differential impedance to vary by ±5Ω along a single pair. For critical applications, we specify spread glass constructions or employ rotation techniques to minimize this effect.

Process Control That Delivers Precision

Achieving consistent 100-ohm differential impedance requires obsessive attention to manufacturing variables. Our production systems monitor and control:

- Trace width and spacing uniformity to ±0.5 mil across panel areas

- Dielectric thickness consistency maintaining ±5% tolerance through controlled lamination

- Copper plating uniformity ensuring consistent trace cross-sections

- Environmental control maintaining 22°C ±1°C temperature and 45% ±5% humidity

We validate 100-ohm performance using both differential TDR measurements and full S-parameter characterization up to 20 GHz on actual production geometry test coupons.

Advanced Techniques for Critical Applications

Some applications demand 100-ohm differential control beyond standard capabilities. For these cases, we offer specialized solutions:

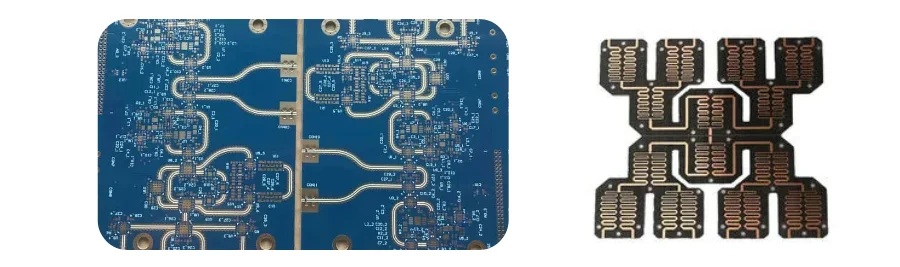

HDI PCB Technology enables complex differential routing in compact designs while maintaining precise 100-ohm control. Sequential lamination and microvias allow optimal trace placement without compromising impedance accuracy.

High-speed PCB Stackup Optimization utilizes advanced materials and layer arrangements to achieve superior 100-ohm differential performance while minimizing crosstalk and EMI.

Embedded Component Integration places precision resistors and capacitors directly in the PCB substrate, eliminating impedance discontinuities at termination points and improving overall signal integrity.

PCB Substrate Selection for 100-Ohm Differential Designs

Advanced Material Options for Differential Signaling

- Ultra-Low Skew Materials — Minimize intra-pair skew through stable dielectric properties and consistent glass weave structures; essential for DDR and high-speed serial interfaces.

- Low-Loss Laminates — Reduce insertion loss and improve eye diagram performance; materials like Nelco N4000-13 SI provide excellent performance for 100-ohm differential applications.

- Controlled Dk Glass — Dielectric constants optimized for 100-ohm differential impedance with minimal frequency variation enable consistent performance across wide bandwidths.

Environmental Stability Factors

100-ohm differential impedance must remain stable across operating conditions:

- High-speed computing systems often experience significant temperature variations that can shift differential impedance and affect timing margins.

- Humidity changes affect dielectric constant and can cause impedance drift in sensitive applications.

- Design compensation through stackup optimization and material selection maintains stable 100-ohm performance across environmental ranges.

Testing and Validation: Trust but Verify

In-Process Monitoring for 100-Ohm Accuracy

Real differential impedance control starts during manufacturing, not after. Our production line incorporates multiple verification points:

After Imaging: Optical measurement confirms differential pair width and spacing meet design targets

Post-Etch: Cross-sectional analysis verifies etch uniformity and final conductor geometry

After Lamination: Dielectric thickness measurement ensures consistent spacing between differential pairs and reference planes

Final Test: Comprehensive differential impedance validation using production-representative test structures

Advanced Characterization Methods

For applications pushing 100-ohm differential performance limits, standard TDR measurements aren't sufficient. We employ sophisticated characterization techniques:

Differential S-Parameter Analysis characterizes impedance behavior across frequency while measuring common-mode rejection and crosstalk performance. This data enables optimization of via transitions and connector interfaces.

Statistical Analysis of production data identifies correlations between process parameters and 100-ohm differential performance. This continuous improvement approach has enabled industry-leading consistency in high-volume production.

Rigid-flex PCB Validation ensures 100-ohm differential impedance is maintained through flex regions and rigid-to-flex transitions, critical for mobile and wearable applications.

Common Pitfalls and How to Avoid Them

Critical Design Flaws That Sabotage 100-Ohm Differential Control

Even with excellent manufacturing, certain design errors will break 100-ohm differential impedance from the start:

- Reference Plane Discontinuities: Splits or gaps in ground planes beneath differential pairs create severe impedance discontinuities that cannot be corrected in fabrication. Always maintain continuous reference planes beneath critical 100-ohm differential routes.

- Unmatched Via Transitions: Differential pairs routed through different via structures will have impedance and timing mismatches. Design via transitions to maintain both 100-ohm impedance and pair matching.

- Neglecting Intra-Pair Spacing: Small variations in trace spacing within differential pairs can cause significant 100-ohm impedance variations. Maintain consistent spacing throughout the route length.

Manufacturing Variations to Anticipate

Understanding realistic fabrication tolerances enables better 100-ohm differential design margins:

- Trace Width: ±0.5 mil typical for precision processes; ±1 mil for standard production

- Trace Spacing: ±0.3 mil achievable with advanced lithography; ±0.5 mil standard

- Dielectric Thickness: ±5% for controlled materials; ±10% for standard prepregs

- Copper Thickness: ±10% typical; affects both impedance and timing

Design Tip: Model these tolerances in simulation tools and work with your PCB fabricator to align 100-ohm differential targets with their process capabilities.

Partner with HILPCB for 100-Ohm Differential Excellence

Successful 100-ohm differential impedance control requires more than manufacturing capability—it demands deep understanding of both electromagnetic physics and practical PCB production realities. At HILPCB, we combine theoretical expertise with proven manufacturing experience to deliver consistent, reliable 100-ohm differential performance for your most demanding applications.

Our commitment extends beyond meeting specifications. We partner with you throughout the design process, offering:

- Design review and optimization to ensure 100-ohm differential manufacturability

- Material selection guidance based on your specific speed and environment requirements

- Prototype validation with comprehensive differential testing and documentation

- Volume production with statistical process control and continuous improvement

- Failure analysis and corrective action when challenges arise

Whether you're designing next-generation memory systems, high-speed serial interfaces, or advanced networking equipment, precise 100-ohm differential impedance control can make the difference between success and failure. Don't leave this critical parameter to chance.