When precision meets reality in industrial automation, actuator PCB design becomes the critical factor determining system success or failure. A pharmaceutical packaging company recently contacted Highleap PCB Factory (HILPCB) with a crisis: their tablet counting machine was experiencing random positioning errors, causing production delays and quality control failures.

This comprehensive guide covers essential design principles and advanced techniques for creating reliable actuator control systems in demanding industrial applications.

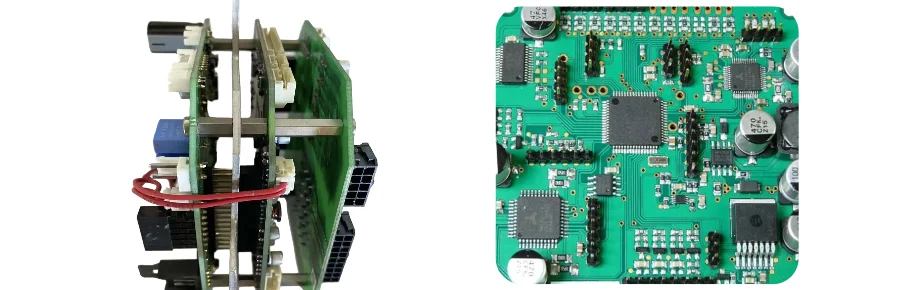

Linear Actuator PCB Design and Control Circuits

Linear actuators require precise control circuits managing both position feedback and motor drive signals. The PCB design must accommodate high-current motor circuits while maintaining clean analog signals for position sensors.

H-Bridge Motor Control: The core component is the H-bridge circuit controlling motor direction and speed. For applications requiring 5A or less, integrated solutions like the DRV8871 provide excellent performance with built-in protection. Higher current applications need discrete MOSFET arrangements on heavy copper PCB designs to handle thermal dissipation.

Position Feedback Systems: Linear actuators use potentiometric sensors, optical encoders, or Hall effect sensors for position feedback. PCB design must provide stable reference voltages and proper filtering for encoder signals. Differential routing becomes critical for maintaining noise immunity over cable distances, requiring careful impedance control for reliable signal transmission.

Power Supply Architecture: Most designs require multiple voltage rails - high voltage for motor drive (12-48V), logic voltage for control circuits (3.3-5V), and precision analog references. Multilayer PCB construction provides dedicated power planes for clean power distribution and effective noise isolation.

Protection and Safety: Overcurrent protection, thermal shutdown, and limit switch inputs protect both actuator and control PCB. Current sensing using shunt resistors enables both protection and closed-loop control algorithms.

Servo Motor Control PCB Components and Layout

Servo motor control demands higher precision and faster response times compared to simple linear actuators. PCB design must support advanced control algorithms while managing electromagnetic interference from high-speed switching.

Advanced Control Integration: Modern servo control uses dedicated motor control ICs like the TMC4671 or ARM Cortex-M microcontrollers implementing field-oriented control (FOC) algorithms. These require fast ADC sampling and precise PWM generation with deterministic timing.

Current Sensing Architecture: Three-phase servo motors require current sensing on at least two phases. Inline shunt resistors with differential amplifiers provide cost-effective solutions, while isolated current sensors offer superior noise immunity in high-power applications.

Encoder Interface Design: Servo systems typically use quadrature or absolute encoders for position feedback. Quadrature interfaces require differential receivers with proper termination, while absolute encoders use SPI, SSI, or BiSS protocols requiring careful signal integrity management.

Gate Driver Implementation: High-performance servo drives use IGBT or MOSFET gate drivers with bootstrap circuits. PCB layout must minimize gate drive loop inductance while providing adequate isolation between control and power circuits.

Thermal Management for High-Power Actuator PCBs

Heat generation in actuator control PCBs comes from power MOSFETs during switching, current sensing resistors, and voltage regulators. Effective thermal management extends component life and maintains control accuracy.

Thermal Design Strategy: High thermal conductivity PCB materials provide superior heat dissipation for power-intensive applications. Thermal vias connect surface-mounted components to internal copper planes, creating three-dimensional heat dissipation networks.

Component Placement Optimization: Separate heat-generating components from temperature-sensitive circuits. Place power components near board edges for heat sink mounting. Position temperature sensors away from heat sources for accurate monitoring.

Advanced Cooling Solutions: External heat sinks become necessary for power levels above 15W. Forced air cooling extends power handling capability, while thermal interface materials improve heat transfer efficiency between components and cooling systems.

Actuator PCB Testing and Troubleshooting Methods

Comprehensive testing ensures actuator PCBs perform reliably across their entire operating range, covering both electrical performance and mechanical operation under various load conditions.

Electrical Validation: Verify power supply operation across load and line voltage ranges. Test current limiting and protection circuits under fault conditions. Validate control signal integrity and timing across temperature ranges using automated test equipment.

Functional Load Testing: Test actuator operation under various mechanical loads to verify control stability. Monitor current consumption, temperature rise, and position accuracy during extended operation cycles to identify potential issues before field deployment.

EMC and Environmental Testing: Conducted emissions testing verifies filter circuit effectiveness. Temperature cycling validates solder joint reliability across industrial temperature ranges. Vibration testing ensures mechanical robustness for harsh industrial environments.

Industrial Applications and Design Requirements

Actuator PCBs serve diverse applications from precision positioning to heavy-duty machinery. Each application presents unique requirements influencing design decisions.

Precision Manufacturing: CNC machine tools require exceptional position accuracy (±5 micrometers) and repeatability. PCB designs must minimize thermal drift and provide stable reference voltages. Noise immunity becomes critical due to electromagnetic interference from surrounding equipment.

Packaging Equipment: High-speed operations demand rapid acceleration and deceleration with precise positioning. Control algorithms must prevent overshoot while maintaining fast response times. Multi-axis coordination requires precise timing and communication between controllers.

Medical and Laboratory: Ultra-quiet operation and precise motion control are essential. PCB designs must minimize electromagnetic emissions and provide exceptional reliability. FDA regulations may require additional documentation and validation procedures.

Safety and Compliance: Many industrial applications require safety-rated systems with redundant monitoring and fail-safe operation. Safety PLCs interface with actuator controllers requiring specific communication protocols and response times.

Our SMT assembly capabilities ensure reliable manufacturing of complex actuator control systems with comprehensive testing and quality assurance procedures.

Frequently Asked Questions

Q: What's the difference between linear actuator PCBs and servo motor control PCBs? Linear actuator PCBs typically control single-axis motion with simpler feedback systems, while servo PCBs handle multi-phase motors with advanced control algorithms and higher precision requirements.

Q: How do you prevent thermal drift in precision applications? Use temperature-compensated components, implement thermal monitoring with software compensation, and design adequate thermal management to minimize temperature variations.

Q: What communication protocols work best for multi-axis systems? EtherCAT provides deterministic real-time communication for synchronized motion. CAN networks offer reliable communication for lower-speed applications with good noise immunity.

Q: How important is EMI shielding for actuator control PCBs? Critical for reliable operation in industrial environments. Proper PCB layout, grounding, and filtering prevent electromagnetic interference from disrupting control signals.

Q: What power levels can actuator PCBs handle? Most actuator control PCBs handle 1-50A continuous current depending on thermal management. Peak currents can reach 2-3 times continuous ratings for short durations.