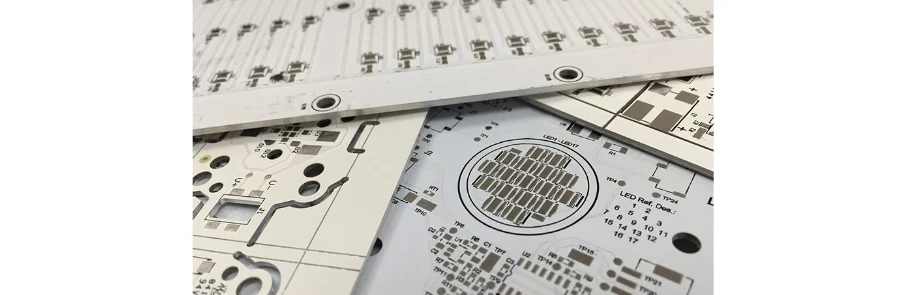

Automotive electronics demand exceptional reliability across extreme operating conditions, making Metal Core PCB technology critical for thermal management in vehicle applications. At Highleap PCB Factory, our IATF 16949 certified manufacturing processes deliver automotive-grade MCPCBs meeting stringent AEC-Q100 requirements. This comprehensive guide covers automotive standards, testing protocols, and compliance strategies for vehicle thermal management solutions.

AEC-Q100 Qualification Requirements

The Automotive Electronics Council's AEC-Q100 standard defines reliability qualification requirements for integrated circuits, with parallel requirements applying to MCPCB substrates supporting these components.

Temperature Grade Classifications: Grade 0 (-40°C to +150°C) for under-hood applications including engine control units and transmission controllers. Grade 1 (-40°C to +125°C) covers most automotive applications including LED headlights and power modules. Grade 2 (-40°C to +105°C) suits passenger compartment electronics. Grade 3 (-40°C to +85°C) addresses infotainment systems. MCPCB substrates must maintain structural integrity and thermal performance across specified temperature ranges without delamination or degradation.

Stress Test Requirements: Temperature cycling (1000 cycles minimum) validates thermal expansion compatibility between aluminum PCB substrates and mounted components. Power temperature cycling simulates real-world power dissipation effects. High-temperature storage (1000 hours) confirms material stability. Temperature humidity bias (1000 hours at 85°C/85%RH) ensures moisture resistance. Thermal shock (-40°C to +125°C, 100 cycles) validates rapid temperature change survival. Comprehensive reliability testing ensures long-term performance.

Mechanical Reliability Testing: Vibration testing per ISO 16750-3 simulates road conditions from 10Hz to 2kHz. Mechanical shock (50g, 11ms) validates impact resistance. Bond strength testing ensures component attachment reliability. Substrate bend testing confirms mechanical robustness. Drop testing validates handling durability during assembly and service.

IATF 16949 Process Requirements

Quality Planning

- APQP (Advanced Product Quality Planning)

- PPAP (Production Part Approval Process)

- FMEA (Failure Mode Effects Analysis)

- Control Plan development

- MSA (Measurement System Analysis)

Process Control

- SPC (Statistical Process Control)

- Cpk >1.33 for critical characteristics

- 100% traceability requirements

- Change control procedures

- Continuous improvement programs

Electric Vehicle MCPCB Applications

Electric and hybrid vehicles create demanding thermal management requirements driving advanced MCPCB implementations across powertrain and charging systems.

Inverter and Motor Control: EV inverters handling 100-400kW require exceptional thermal management. Copper core PCB substrates provide maximum thermal conductivity for IGBT/SiC modules. Direct cooling integration through liquid-cooled base plates. Thermal interface materials optimize heat transfer from power modules. High-voltage isolation (>2.5kV) ensures safety while maintaining thermal performance. Advanced thermal simulation validates cooling system design.

On-Board Charger Systems: AC/DC conversion generates significant heat requiring efficient dissipation. Power densities exceeding 50W/in³ demand optimized thermal designs. Bidirectional charging capabilities for V2G applications increase thermal challenges. Thermal cycling from daily charging stresses solder joints requiring robust designs. EMI shielding integration maintains signal integrity while enabling cooling airflow.

Battery Management Systems: Cell balancing circuits generate localized heating requiring thermal spreading. Temperature monitoring accuracy depends on sensor thermal coupling. Safety shutdown circuits must operate reliably at temperature extremes. Thermal runaway detection requires fast response and fail-safe operation. Potting materials for environmental protection impact thermal management strategies.

LED Automotive Lighting Standards

Automotive LED lighting applications leverage MCPCB thermal management ensuring photometric stability and extended lifetime meeting regulatory requirements.

Headlight Thermal Requirements: Matrix LED headlights with 20-100 individual LEDs require precise thermal control. Junction temperatures must remain below 125°C maintaining luminous flux. Color temperature stability (±200K) requires consistent thermal management. Adaptive driving beam systems increase thermal cycling frequency. LED PCB board designs optimize both thermal and optical performance following strict MCPCB design rules.

Regulatory Compliance Standards: ECE regulations define photometric requirements affecting thermal design. SAE standards specify environmental testing including thermal cycling. FMVSS requirements impact reliability and safety considerations. Color rendering index maintenance requires stable junction temperatures. Lifetime requirements (15 years/150,000 miles) drive conservative thermal designs.

DRL and Signal Lighting: Daytime running lights operate continuously requiring efficient heat dissipation. Turn signals experience frequent thermal cycling affecting solder joint reliability. Brake lights must maintain output during extended activation. Position lights require minimal power consumption driving LED efficiency optimization. Sequential indicators create moving heat sources requiring distributed thermal management.

Material Selection for Automotive

Automotive applications require careful material selection balancing performance, reliability, and cost across extended operating lifetimes.

Substrate Material Qualification: Aluminum 5052-H32 provides corrosion resistance and thermal performance. Aluminum 6061-T6 offers superior strength for structural applications. Copper substrates enable extreme power density designs. Surface treatments including anodizing and chromate conversion prevent corrosion. Material traceability ensures consistent quality and regulatory compliance.

Dielectric System Requirements: Glass transition temperature >170°C prevents delamination at operating extremes. Thermal conductivity 2.0-5.0 W/m·K balances isolation and heat transfer. Breakdown voltage >4kV/mm ensures safety margins. CTE matching minimizes stress during thermal cycling. Moisture absorption <0.3% maintains dimensional stability.

Solder Mask and Finishes: High-temperature solder masks withstand 150°C continuous operation. UV-stable formulations prevent degradation from sunlight exposure. Chemical resistance to automotive fluids including oil, coolant, and fuel. Surface finishes including ENIG and immersion silver provide reliable soldering. Conformal coating compatibility ensures environmental protection.

Automotive Testing Matrix

| Test Type | Conditions | Duration | Pass Criteria |

|---|---|---|---|

| Temperature Cycling | -40°C to +125°C | 1000 cycles | No delamination |

| Thermal Shock | -40°C to +125°C | 100 cycles | No cracks |

| HAST | 110°C/85%RH/33psi | 264 hours | <10% degradation |

| Vibration | 10-2000Hz, 10g | 8 hours/axis | No failures |

Automotive MCPCB Manufacturing & Assembly Solutions | Highleap PCB Factory

At Highleap PCB Factory, we specialize in comprehensive manufacturing and assembly services for automotive Metal Core PCBs (MCPCBs), supporting your projects from design validation through high-volume production. Our advanced facilities, strict quality management, and experienced engineering team ensure every MCPCB meets the demanding requirements of automotive electronics—including reliability, heat dissipation, and full traceability.

Why Choose Highleap PCB Factory for Automotive MCPCB Projects?

1. Robust Quality Control for Automotive Standards

- Our manufacturing process follows APQP and PPAP protocols, ensuring every stage is traceable and fully documented.

- We provide MCPCB design rule verification and deliver detailed compliance reports with every batch.

- All products undergo stringent inspection, with first-pass yield rates above 99% and Cpk >1.67 for critical processes. Every shipment includes a certificate of conformance and batch traceability information.

2. Professional Failure Analysis & Continuous Improvement

- Our in-house team uses advanced methods—cross-section analysis, SEM, X-ray, and more—to quickly identify issues such as delamination, copper migration, and thermal degradation.

- We apply 8D root cause analysis and corrective actions, helping you resolve problems quickly while continuously optimizing design and manufacturing processes for greater reliability.

3. Smart Supply Chain Management & On-Time Delivery

- We rigorously qualify suppliers to automotive standards and maintain dual-source strategies for critical materials, ensuring stable supply and risk mitigation.

- Localized sourcing and dynamic inventory management help lower costs and guarantee fast, reliable deliveries for your automotive projects.

4. Advanced Thermal Management Solutions

- We offer innovative thermal management PCB technologies, including double-sided MCPCB, embedded components, and integrated liquid cooling—ideal for high-power automotive lighting, power modules, and EV electronics.

- Our engineering team tailors thermal solutions to your specific application, helping you achieve optimal performance even in the most demanding environments.

5. State-of-the-Art Manufacturing and Turnkey Assembly

- Our factory is equipped with automated AOI, X-ray inspection, flying probe, and ionic contamination testing to guarantee product quality.

- As a one-stop partner, we provide MCPCB assembly services alongside PCB fabrication, simplifying your supply chain and improving project efficiency.

- Our application engineers offer DFM reviews, prototyping support, and technical guidance from project kickoff to mass production.

Whether you need automotive MCPCBs for lighting, power control, or next-generation EV applications, Highleap PCB Factory delivers proven quality, advanced thermal management, and reliable supply—all backed by responsive technical support.

Contact us today for a tailored quote and let our team help drive your automotive electronics project to success!

Cost Considerations for Automotive MCPCB

Understanding the cost implications of automotive MCPCB specifications helps optimize designs balancing performance requirements against budget constraints. Our MCPCB cost analysis provides detailed guidance for automotive applications.

Premium Material Costs: Automotive-grade materials command 20-50% premium over standard versions. High-temperature dielectrics add 30-40% to material costs. Extended qualification testing increases development expenses. Long-term supply agreements help stabilize pricing. Volume commitments reduce per-unit costs for production programs.

Testing and Validation Expenses: AEC-Q100 qualification requires extensive testing representing significant upfront investment. Environmental testing chambers and specialized equipment increase testing costs. Third-party validation adds credibility but increases expenses. Accelerated life testing compresses time but requires specialized facilities. Statistical analysis software and personnel expertise add to qualification costs.

Driving Automotive Innovation Through Thermal Excellence

Automotive electronics evolution toward electrification and autonomy intensifies thermal management challenges. MCPCBs provide essential thermal solutions enabling higher power densities, improved reliability, and extended operating lifetimes. Our IATF 16949 certified processes and comprehensive testing capabilities ensure automotive-grade quality meeting the industry's demanding requirements.

Partner with Highleap PCB Factory for automotive MCPCB solutions combining thermal performance with uncompromising reliability. From concept through production, our engineering expertise and manufacturing excellence support your automotive thermal management challenges. Contact us today to discuss your automotive MCPCB requirements and discover how our capabilities accelerate your vehicle electronics development.