Why Understanding How to Buy PCBs Matters

Purchasing PCBs is more than just uploading files and placing an order. Whether you’re buying prototype PCBs, multi-layer production boards, or full PCB assembly (PCBA) services, making the right decisions early can save time, cost, and ensure product reliability. For engineering teams and manufacturing buyers alike, knowing how to buy PCBs-from board specification to assembly and testing-can differentiate between smooth production and costly delays.

In this guide, we explore the key steps and critical criteria when you decide to buy PCBs or contract PCB assembly services. We’ll cover material selection, quote preparation, supplier evaluation, cost drivers, and how to avoid common pitfalls in the PCB buying process.

Key Steps When You Buy PCBs

1. Define Your Requirements

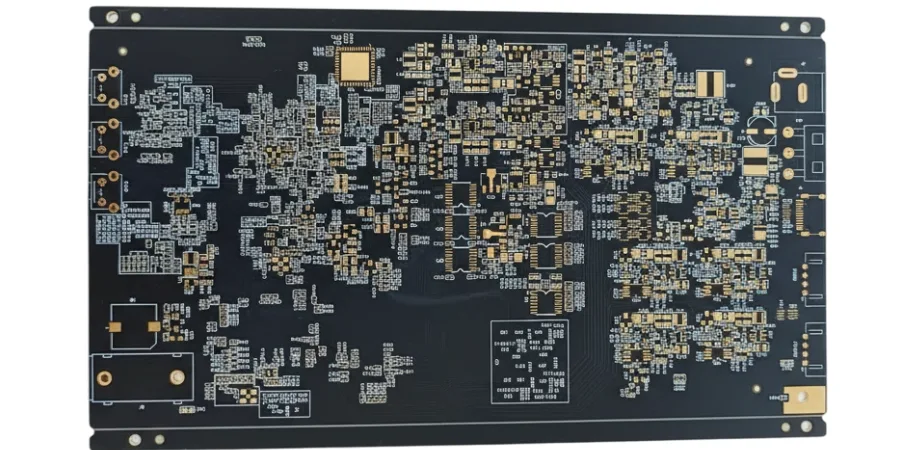

Start by clarifying what you need: Is it a prototype PCB, a short-run pilot, or full volume production? The board’s function (e.g., high-speed digital, power electronics, medical device) influences materials, layer count, impedance requirements, and fabrication features.

2. Prepare Complete Design Data

To receive accurate quotes, you’ll need to provide manufacturing data such as Gerber files, drill files, layer stackup, BOM (if assembly is involved), board size, copper thickness, material type (e.g., FR-4, Rogers), finish (ENIG, HASL) and any polyimide/flex requirements. Also include quantities, board panelization, solder mask colour, silkscreen specs, and test/inspection needs.

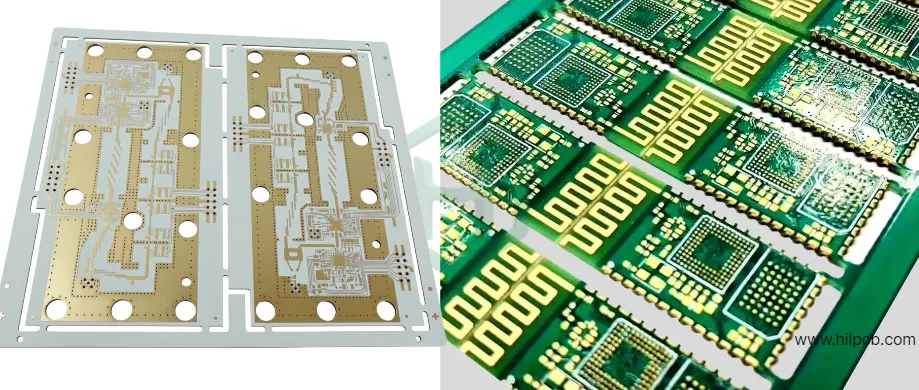

3. Choose Manufacturing Specifications

Material and process choices influence cost and lead time. Factors include: layer count, board dimensions, copper weight, substrate (standard FR-4 vs high-frequency), controlled impedance, surface finishes, via types (blind/buried), and if turnkey assembly is required. Also determine whether you’ll buy bare PCBs or full PCB assembly (PCBA) sourcing.

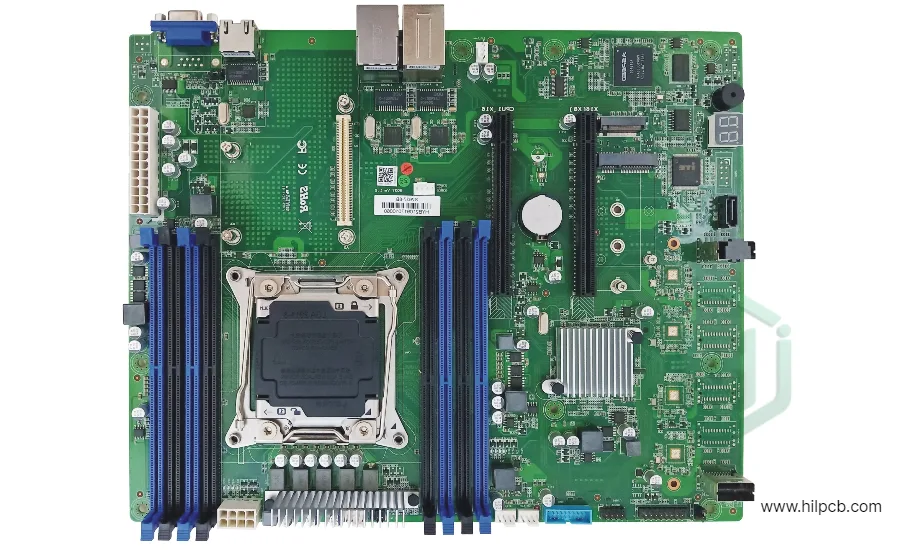

4. Evaluate Suppliers and Manufacturing Partners

Not all PCB vendors are equal. Ask: What is their experience with your board type (e.g., HDI, flex, rigid-flex)? What are their lead times? What quality certifications do they hold? Do they support DFM/DFT (design for manufacturing/test)? Comparing supplier capabilities on volume, turnaround, testing, and post-production support helps you pick the right partner instead of just the lowest cost.

5. Understand Cost Drivers

Several factors affect pricing: board size, layer count, material selection, finishes, quantity, lead time, complexity (via types, microvias), and post-process testing. Lower cost isn’t always best if reliability or performance is compromised. Be aware of hidden costs: tooling, setup, shipping, customs, and spare boards for testing.

6. Review Lead Times, Testing & Quality Assurance

Confirm delivery times for prototypes vs full runs, the inspection methods (AOI, X-ray, ICT), and whether the supplier offers comprehensive testing. These affect throughput and time-to-market. Quality assurance during PCB fabrication and assembly reduces field failures and rework.

7. Arrange Logistics, Shipping & After-sales

Consider shipping logistics (air, sea), customs/import duties, packaging to protect boards, and after-sales support for troubleshooting or reorders. These often impact total cost and risk.

Checklist: Buying PCBs & PCB Assembly - Quick Reference

- Define board type: Prototype vs Production

- Provide full design files: Gerbers, BOM, stackup

- Select material & process: substrate, layer count, copper weight

- Choose finish & via structure: ENIG, HASL, blind/buried vias

- Quote multiple vendors: Compare cost, lead time, capabilities

- Review supplier credentials: Certifications, equipment, reliability

- Confirm testing and quality methods: AOI, ICT, X-ray

- Plan shipping and logistics: Packaging, customs, transit time

- Plan for spares: Extra boards for testing and failure mitigation

- Establish communication: Good supplier will liaise on specs, DFM, changes

Avoiding Common Mistakes When You Buy PCBs

- Under-estimating design constraints: Ignoring DFM/DFT rules may cause manufacture delays. Poorly defined stackups or incompatible materials lead to yield issues.

- Choosing solely by lowest cost: Lowest price may mean longer lead time, less testing, or weak documentation.

- Late changes & specifications updates: Changing stackup or layer count late in the process can dramatically affect cost and schedule.

- Ignoring lead time differences: Prototype runs and mass production runs often have vastly different timelines.

- Not planning for assembly: If your order includes PCB assembly (PCBA), ensure component sourcing, placement, and testing are coordinated.

Why Detailed Buying Process Matters for PCB Manufacturability & Reliability

When you adopt a structured approach to buying PCBs-or contracting PCB assembly-you improve manufacturability, reduce risk, and enhance product reliability. A well-defined specification ensures the board supplier understands your requirements and supports DFM/DFT reviews. This prevents yield losses, avoids design revisions, and helps you stay on schedule.

For example, if your board features high-speed digital traces or controlled impedance, specifying the correct stackup and communicating this to the fabrication house early avoids signal integrity issues post-assembly. Similarly, aligning your PCBA partner’s sourcing and inspection capabilities means fewer surprises during assembly and testing.

How to Identify the Best PCB Manufacturer for Your Needs

Selecting the right PCB manufacturer is essential for ensuring quality, speed, and cost-effectiveness. Here’s how you can evaluate the best options:

- Certifications and Standards

Ensure the manufacturer complies with international standards such as ISO 9001, IPC-2221, and UL certification. These certifications indicate adherence to quality assurance protocols and reliability. - Experience with Complex Designs

If your project requires specialized PCBs like high-density interconnect (HDI) or rigid-flex designs, it’s crucial to select a manufacturer experienced in these technologies. - Design and Testing Capabilities

A good PCB manufacturer should offer DFM (Design for Manufacturability) and DFT (Design for Testability) services to optimize your design for mass production and ensure easier fault detection. - Turnaround Time

For time-sensitive projects, consider manufacturers who offer rapid prototyping and short lead times. Many manufacturers provide fast-turn PCB services with quick turnaround times for prototypes and small batches. - Support for Customization

If your project involves custom materials, finishes, or unique specifications (like controlled impedance or high-frequency designs), make sure the manufacturer has the capability to handle such customizations.

Conclusion

Knowing how to buy PCBs and PCB assembly services is essential for electronics developers, hardware engineers, and manufacturing buyers. From defining your requirements, preparing design data, evaluating suppliers, understanding cost drivers, and avoiding pitfalls, each step contributes to a smoother production flow and better outcome. Whether you’re ordering a single prototype board or a high-volume multi-layer production run, following these guidelines will help you source quality PCBs that align with your design, budget, and timeline.

By using a strategic checklist and embracing supplier evaluation rather than only price comparison, you elevate your PCB buying process. The result: better performance, fewer surprises, faster time-to-market, and a stronger foundation for your PCB projects.

FAQ

Q1: What is the minimum quantity I can order when buying PCBs?

A1: It depends on the manufacturer. Many PCB shops support prototype runs (e.g., 1-10 boards), but lower quantities may carry higher per-unit cost due to setup and panelization overhead.

Q2: How long does it typically take from order to delivery when buying PCBs?

A2: Prototype boards may be available in a few days to a week; production runs vary widely depending on layer count, complexity, and volume-lead times can be several weeks.

Q3: What information do I need to supply a PCB manufacturer when buying boards?

A3: At minimum: Gerber files, drill files, stackup or layer count, board dimensions, material type, copper thickness, surface finish, quantity, and any assembly or testing requirements.

Q4: Can I buy PCBs and also have them assembled (PCBA)?

A4: Yes-many PCB manufacturers also provide PCB assembly (PCBA) services. When buying PCBs+assembly, you’ll supply BOM (Bill of Materials), pick-and-place data, and testing requirements.

Q5: How do I compare quality among PCB suppliers when buying boards?

A5: Ask about certifications (such as ISO 9001, IPC standards), testing methods (AOI, X-ray, ICT), yield history, and review customer case studies. Checking manufacturability guidelines and supplier responsiveness helps gauge reliability.