Circuit board assembly represents the critical transformation phase where bare PCBs become functional electronic products. This comprehensive process involves precise component placement, soldering techniques, and rigorous quality control to ensure reliable performance across diverse applications.

Professional assembly services combine advanced manufacturing technologies with skilled expertise to deliver products that meet stringent quality standards. Understanding assembly processes helps designers optimize their custom circuit board design layouts for manufacturability while ensuring cost-effective production.

Understanding PCB Assembly Fundamentals

Circuit board assembly encompasses multiple interconnected processes that must work harmoniously to produce reliable electronic products. The assembly workflow begins with component preparation and progresses through placement, soldering, inspection, and testing phases.

Modern assembly facilities utilize sophisticated equipment including pick-and-place machines, reflow ovens, and automated optical inspection systems. These technologies enable high-precision component placement and consistent soldering quality while maintaining efficient production throughput.

The foundation of successful assembly lies in understanding how design decisions impact manufacturability. Component selection, footprint design, thermal considerations, and test point accessibility all influence assembly efficiency and final product reliability. Integration with circuit board manufacturing processes ensures seamless transition from bare boards to finished assemblies.

Assembly Process Overview

Component Preparation

Inspection, testing, and preparation of components for assembly

Solder Paste Application

Precise stencil printing of solder paste onto PCB pads

Component Placement

High-precision automated placement of surface mount components

Reflow Soldering

Controlled heating process to form permanent solder joints

Surface Mount Technology (SMT) Assembly

Surface Mount Technology represents the backbone of modern electronic assembly, enabling miniaturization and high component density. SMT assembly involves placing components directly onto circuit board surface pads rather than inserting leads through holes.

The SMT process begins with solder paste application using precision stencils. Paste composition, thickness, and coverage directly affect joint quality and reliability. Modern facilities use automated stencil printers with vision systems to ensure consistent paste deposition across production runs.

Component placement follows paste application, utilizing high-speed pick-and-place machines capable of positioning thousands of components per hour. Vision systems verify component orientation and placement accuracy before final positioning, ensuring optimal joint formation during reflow.

SMT Assembly Capabilities

Fine Pitch Components: Handling components with pitches down to 0.3mm for advanced integrated circuits

Micro Components: Assembly of 01005 and smaller passive components for ultra-compact designs

High Pin Count Devices: BGA, QFN, and other advanced packaging technologies

Mixed Technology: Combining SMT with through-hole components in hybrid assemblies

Reflow soldering completes the SMT process through controlled thermal profiles. Temperature curves are optimized for specific solder paste formulations and component thermal requirements, ensuring reliable joint formation without thermal damage to sensitive components.

Through-Hole Assembly and Mixed Technology

Through-hole assembly remains essential for components requiring mechanical strength or high current carrying capacity. This process involves inserting component leads through drilled holes and soldering them to pads on the opposite side of the PCB.

Wave soldering typically handles through-hole components in volume production, with the PCB passing over a wave of molten solder. Selective soldering offers greater precision for complex assemblies with mixed component types or heat-sensitive areas requiring localized soldering.

Hand soldering provides maximum flexibility for prototypes, repairs, or specialized components. Skilled technicians use temperature-controlled irons and appropriate flux to create reliable joints while avoiding thermal damage to surrounding components.

Through-Hole Assembly Applications

Through-hole technology excels in applications demanding robust mechanical connections. Power connectors, transformers, large capacitors, and components subject to mechanical stress benefit from through-hole mounting. The process also accommodates components unavailable in surface mount packages.

Mixed technology assemblies combine SMT and through-hole components on the same PCB. This approach requires careful process planning to optimize reflow profiles while preventing damage to temperature-sensitive components during subsequent soldering operations.

For successful circuit board designs incorporating through-hole components, designers must consider hole sizes, pad geometries, and thermal relief patterns. These factors directly impact assembly yield and long-term reliability.

Advanced Assembly Techniques and Technologies

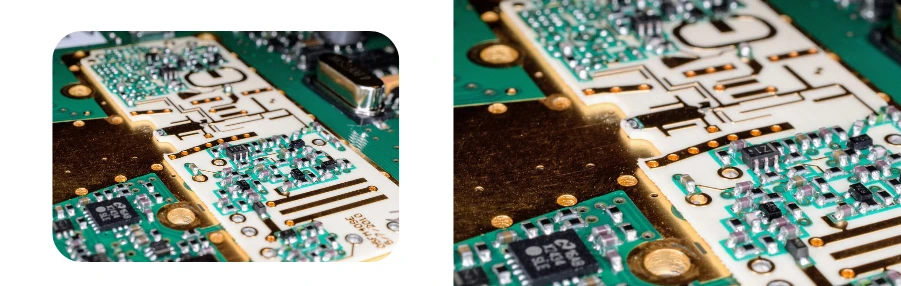

Modern electronics demand increasingly sophisticated assembly techniques to accommodate miniaturization trends and performance requirements. Advanced packaging technologies including Ball Grid Arrays (BGAs), Chip Scale Packages (CSPs), and System-in-Package (SiP) solutions require specialized handling capabilities.

BGA assembly presents unique challenges due to hidden solder joints beneath the component body. X-ray inspection systems enable quality verification of these concealed connections, detecting voids, bridges, or incomplete joints that could compromise reliability.

Specialized Assembly Services

Flip Chip Assembly: Direct chip attachment for high-performance applications requiring minimal interconnect length Wire Bonding: Creating electrical connections using fine wires for hybrid circuits and specialized packaging Die Attach: Precise positioning and bonding of semiconductor dies in custom packages Conformal Coating: Protective coating application for harsh environment applications

Component-on-Board (COB) assembly involves mounting bare semiconductor dies directly onto PCBs, eliminating traditional packaging overhead. This technique enables ultra-compact designs while providing superior electrical and thermal performance.

Flexible and rigid-flex assemblies require specialized handling to prevent damage during component placement and soldering. Fixtures and tooling must accommodate the flexible sections while maintaining precise component alignment throughout the assembly process.

Quality Control, Testing, and Design Optimization in PCB Assembly

Quality control is essential to ensuring reliable PCB assembly. It starts with incoming component inspection to verify parts and prevent defects from entering the production line. Solder paste inspection follows immediately after stencil printing, ensuring correct paste volume, coverage, and registration, which helps identify issues early and reduce rework costs. Post-placement inspection with Automated Optical Inspection (AOI) verifies component placement accuracy before reflow soldering.

Comprehensive Testing and Advanced Assurance

In-Circuit Testing (ICT) checks individual component values and basic circuit functionality, quickly detecting issues early in production. Functional testing simulates real-world operating conditions, ensuring the circuit performs as expected under actual usage. Boundary scan testing leverages JTAG interfaces to verify interconnections and component functionality without physical test probes.

Advanced methods like X-ray inspection offer non-destructive examination of hidden solder joints, essential for BGA and other advanced packages. Flying probe testing provides flexible, fixture-free in-circuit testing, ideal for prototypes or low-volume production. Real-time Statistical Process Control (SPC) monitors assembly parameters to maintain consistent quality throughout production runs.

For comprehensive validation, integration with circuit board testing services ensures electrical parameters, signal integrity, and reliability are verified under various operating conditions.

Assembly Design for Manufacturing (DFM)

DFM ensures that PCB layouts are optimized for efficient, reliable assembly. Early collaboration between design and manufacturing teams prevents costly redesigns, improving production yield and quality. Guidelines for component placement, thermal management, and panel design help ensure smooth assembly and testing operations.

DFM Best Practices include:

- Standardization: Use common component packages to reduce setup time and simplify inventory.

- Accessibility: Ensure critical components are accessible for inspection and rework.

- Thermal Management: Properly distribute heat-generating components to avoid thermal stress.

- Solder Joint Design: Optimize pad geometries and thermal relief patterns for better solderability and reliability.

Strategic placement of fiducials enables accurate machine vision alignment, while proper test point accessibility facilitates efficient testing and troubleshooting.

For optimal circuit board manufacturing and assembly integration, designers must consider fabrication constraints like via-in-pad designs, which require special processing for reliable component attachment.

Choosing Professional PCB Assembly Services

Selecting the right assembly partner is critical to achieving reliable, cost-effective production. A qualified provider should combine technical expertise, robust quality systems, and scalable services to meet both prototype and high-volume needs.

Key Evaluation Factors

When evaluating potential partners for buying circuit boards, consider:

- Technical Expertise: Proven capabilities in component handling, advanced equipment, and process knowledge.

- Quality Systems: Certifications such as IPC-A-610 and ISO standards, supported by automated inspection and statistical process control.

- Supply Chain Management: Strong sourcing networks, inventory control, and supplier qualification to ensure component reliability.

- Engineering Support: Services such as DFM analysis, test development, and process optimization to reduce risk and improve yield.

- Service Integration: Ability to provide procurement, assembly, testing, and fulfillment within a single workflow for simplified project management.

Geographic location also matters—local partners may offer faster prototyping and collaboration, while global providers often bring cost advantages for large-scale production. Clear communication protocols and structured project management help prevent delays and maintain schedule integrity.

The transition from prototyping to production assembly should be seamless. Partners experienced in both phases provide valuable continuity, ensuring lessons learned in development carry into mass manufacturing. For complex designs like multilayer circuit boards, specialized assembly expertise becomes even more critical for achieving reliable results.