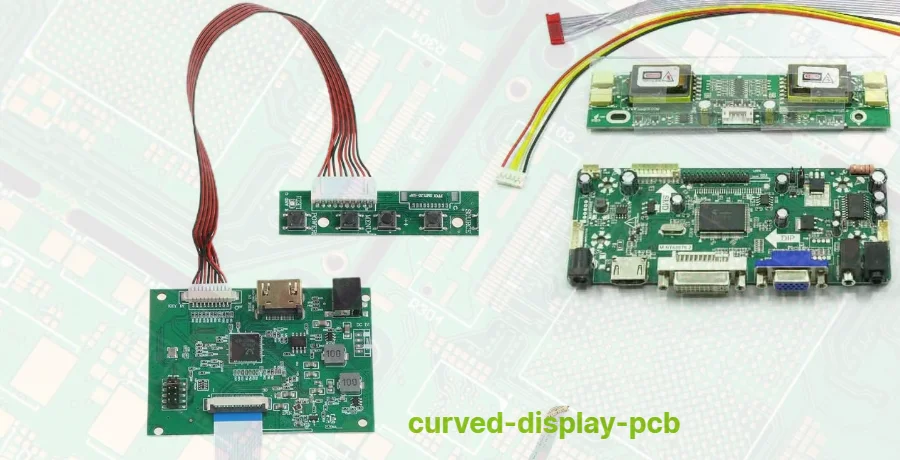

Highleap PCB Factory delivers precision curved display PCB manufacturing for monitors, televisions, automotive displays, and specialized visualization systems. Our expertise encompasses curved screen circuit design, precision forming processes, and specialized assembly enabling seamless integration with curved display panels. From gaming monitors to automotive instrument clusters, we provide manufacturing excellence for curved display innovations.

Curved display PCB technology enables immersive visual experiences through precisely engineered three-dimensional geometries. These specialized boards maintain consistent electrical performance across curved profiles while managing mechanical stress and thermal considerations. Highleap PCB Factory combines advanced forming capabilities with display electronics expertise delivering curved display solutions meeting exacting performance standards.

Curved Monitor PCB Design Requirements

Modern curved display PCB design requires sophisticated analysis balancing electrical performance with mechanical requirements. Curved monitor boards integrate high-speed video processing, backlighting control, and power distribution across precisely formed three-dimensional structures maintaining signal integrity throughout.

Core Technical Specifications:

• Curvature Radius: 1000-4000mm for monitors, 2000-6000mm for televisions • Thickness Requirements: 0.8-2.0mm maintaining structural integrity • Layer Construction: 4-10 layers supporting high-speed differential signals • Material Properties: Controlled CTE preventing warpage through temperature cycles

High-speed PCB design techniques ensure signal quality for 4K and 8K resolutions across curved geometries. Impedance control maintains consistency through formed sections critical for HDMI and DisplayPort interfaces.

Critical Design Factors:

Stress analysis identifies concentration points requiring reinforcement or design modification. Thermal management distributes heat from processing components preventing hot spots affecting display performance. EMI shielding design accommodates curved geometry while maintaining effectiveness. Component placement optimization considers mechanical stress during forming processes.

Curved Screen PCB Manufacturing Process

Curved display PCB manufacturing employs specialized forming techniques achieving consistent curvature while preserving electrical and mechanical properties.

Advanced Forming Technologies:

Multi-zone heating systems provide precise temperature control during forming operations. Custom tooling ensures consistent curvature across production batches. Gradual forming processes minimize stress preventing delamination or copper fracturing.

Manufacturing Excellence:

• Pre-forming Preparation: Stress relief and moisture conditioning • Forming Process: Controlled temperature, pressure, and time parameters • Post-forming Treatment: Dimensional stabilization and stress relief • Quality Verification: 3D measurement confirming curvature specifications

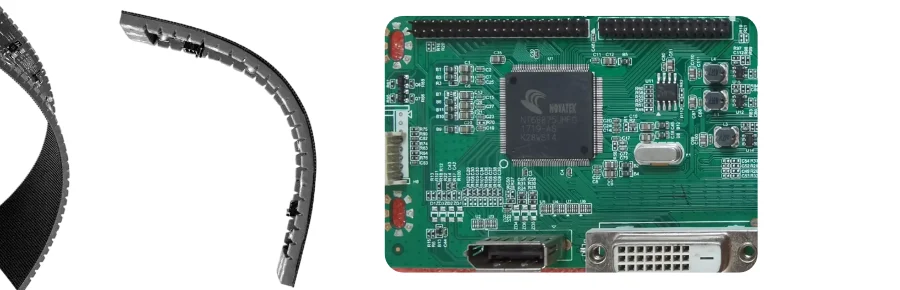

Rigid-flex PCB techniques enable selective flexibility facilitating installation while maintaining structural integrity in curved sections.

Sequential processing ensures consistent results across production volumes. In-process monitoring detects variations enabling immediate correction maintaining quality standards.

Curved TV PCB Assembly Techniques

Curved display PCB assembly requires specialized fixtures and processes accommodating three-dimensional geometries while ensuring reliable component attachment.

Specialized Assembly Technologies:

Custom fixtures support curved boards during component placement maintaining position accuracy. Modified reflow profiles accommodate varying thermal masses across curved structures. Selective soldering enables through-hole component assembly on pre-formed boards.

Component Integration Capabilities:

• Display Interfaces: HDMI, DisplayPort, and proprietary connections • Processing Elements: Graphics processors and timing controllers • Power Systems: LED drivers and voltage regulation • Control Interfaces: Touch controllers and ambient light sensors

Through-hole assembly techniques adapted for curved boards ensure reliable mechanical connections for connectors and heavy components.

Conformal coating application follows surface contours providing environmental protection without adding stress. Automated optical inspection systems calibrated for curved surfaces ensure assembly quality.

Curved Gaming Monitor PCB Applications

Curved display PCBs enable enhanced visual experiences across diverse markets from immersive gaming to automotive instrumentation with improved ergonomics and aesthetics.

Gaming and Entertainment:

Ultra-wide gaming monitors leverage curved displays for peripheral vision enhancement improving competitive gaming experiences. Home theater systems employ curved screens for cinematic immersion. Virtual production studios utilize curved LED walls creating realistic environments for film production.

Automotive Applications:

Digital instrument clusters follow dashboard contours integrating seamlessly with vehicle interiors. Center console displays curve toward drivers improving accessibility and reducing glare. Heads-up displays project onto curved windshields providing navigation and safety information.

Commercial and Professional:

Command centers employ curved video walls for comprehensive monitoring capabilities. Medical imaging systems utilize curved displays matching natural viewing angles. Simulation systems create immersive training environments with wraparound displays.

Curved Display PCB Cost Factors and Lead Times

Highleap PCB Factory provides comprehensive curved display PCB solutions from concept development through volume production, supporting global display manufacturers with specialized expertise and proven reliability.

Engineering Capabilities:

• Finite element analysis predicts board behavior through forming processes • Thermal simulation ensures adequate cooling across curved geometries • Signal integrity verification confirms performance at target resolutions • Design for manufacturing reviews identify optimization opportunities

Production Excellence:

Large volume assembly capabilities support mass production requirements for consumer displays. Flexible manufacturing systems accommodate custom curvatures for specialized applications. Advanced planning systems ensure on-time delivery meeting production schedules.

Quality Systems:

Dimensional verification confirms curvature accuracy using coordinate measuring machines. Electrical testing validates signal integrity across curved structures. Environmental testing ensures performance through temperature cycling and humidity exposure. Mechanical testing confirms structural integrity through shipping and handling simulation.

Global Support:

International logistics expertise ensures safe delivery of curved assemblies worldwide. Technical support provides design assistance and troubleshooting throughout product lifecycle. Supply chain management ensures material availability for continuous production. Warranty programs demonstrate confidence in manufacturing quality and reliability.

Partnership Benefits:

Working with Highleap PCB Factory provides access to specialized curved display manufacturing expertise, advanced forming technologies, and commitment to quality essential for successful product deployment. Continuous investment in capabilities and training maintains leadership in curved display PCB manufacturing supporting next-generation display innovations. Our proven track record with leading display manufacturers demonstrates capability delivering complex curved display solutions meeting demanding market requirements.

Frequently Asked Questions About Curved Display PCB

Q: What tolerances can you achieve for curved display PCB radius?

A: We maintain ±2% tolerance on standard curvatures and ±1% for critical applications. 3D measurement systems verify specifications with custom tooling available for unique requirements.

Q: How do you prevent component damage during board forming?

A: Components are typically assembled after forming. Low-stress techniques and protective measures ensure board integrity throughout the process.

Q: What testing validates curved display PCB reliability?

A: Testing includes dimensional verification, electrical continuity, signal integrity analysis, and environmental cycling to ensure long-term performance.

Q: Can you support custom curvatures for specialized applications?

A: Yes, we develop custom tooling for unique requirements with engineering analysis and prototype services for design verification.