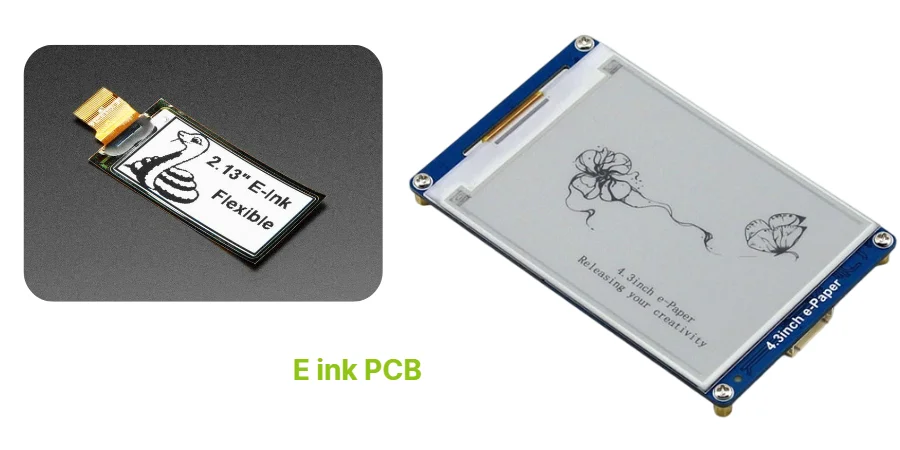

Highleap PCB Factory delivers specialized E-ink PCB manufacturing solutions for electronic paper displays, e-readers, and digital signage applications. Our expertise encompasses electronic paper circuit board fabrication, flexible substrate integration, and precision assembly that enable low-power, high-contrast display technologies. From consumer e-readers to industrial electronic shelf labels, we provide manufacturing excellence for electronic paper display innovations.

E-ink PCB technology enables revolutionary display applications with ultra-low power consumption and excellent daylight readability. These specialized boards integrate complex driver circuits while maintaining compatibility with flexible substrates and unique material requirements. Highleap PCB Factory combines advanced manufacturing capabilities with deep electronic paper expertise to deliver E-ink display boards that exceed industry standards.

What is E-ink PCB and How Does It Work

Modern E-ink PCB design demands exceptional low-power optimization while supporting complex display matrix control. Electronic paper displays integrate specialized driver ICs, high-voltage generation circuits, and precise timing controllers on boards optimized for minimal power consumption and extended battery life.

Core Technical Specifications:

• Layer Construction: 4-8 layer designs with controlled impedance for display signal integrity • Ultra-Low Power: Optimized traces and power planes supporting microamp standby currents • High-Voltage Support: Specialized insulation for 15-40V display driving voltages • Temperature Stability: Materials maintaining performance from -25°C to 85°C

Flex PCB technology enables seamless integration with flexible E-ink displays while maintaining reliable interconnections. Advanced polyimide substrates provide mechanical flexibility essential for curved and bendable electronic paper applications.

Critical Design Factors:

Power management circuits support extended battery operation with sophisticated sleep modes and instant wake capabilities. Display refresh controllers manage partial update sequences minimizing power consumption during content changes. Signal distribution networks ensure uniform pixel response across large display areas while preventing ghosting artifacts.

E-ink Display PCB Materials and Specifications

E-ink PCB manufacturing leverages specialized fabrication technologies to achieve reliable performance with unique material combinations essential for electronic paper applications.

Advanced Materials:

High-TG PCB materials ensure dimensional stability during assembly processes while maintaining compatibility with E-ink display bonding requirements. Specialized surface treatments optimize adhesion for anisotropic conductive film connections typical in display applications.

Precision Manufacturing:

• Substrate Options: Rigid, flexible, and rigid-flex configurations for diverse applications • Surface Finishes: ENIG and OSP optimized for display connector reliability • Via Technology: Controlled depth drilling for blind and buried via structures • Quality Systems: 100% electrical testing with custom fixtures for display interfaces

Sequential lamination processes create complex stackups supporting high-density routing beneath display driver ICs. Laser processing achieves precise openings for display interconnections while maintaining substrate integrity.

Electronic Paper PCB Assembly Process

E-ink PCB assembly requires specialized techniques handling display-specific components from high-voltage drivers to precision timing crystals essential for refresh control.

Precision Assembly Technologies:

SMT assembly systems employ specialized profiles for temperature-sensitive display components. Multi-stage reflow processes ensure reliable solder joints while protecting E-ink display connections from thermal damage.

Critical Integration Capabilities:

• Display Controllers: Complex QFP and BGA packages with hundreds of connections • Power Management: Boost converters generating display driving voltages • Interface Circuits: USB, SPI, and I2C communication for system integration • Connector Systems: ZIF and board-to-board connectors for display modules

Environmental protection through conformal coating and underfill materials ensures long-term reliability in diverse operating conditions. Comprehensive testing validates functionality including display communication protocols and power consumption specifications.

E-Reader PCB vs Traditional Display PCB Differences

E-ink PCBs enable diverse electronic paper applications from personal e-readers to large-format digital signage with exceptional visibility and minimal power requirements.

E-Reader Technologies:

Consumer e-readers demand ultra-compact PCB designs supporting weeks of battery life. Touch interface integration enables intuitive navigation while maintaining low power consumption. Wireless connectivity through WiFi and cellular modules enables content synchronization without compromising battery performance.

Industrial Applications:

Electronic shelf labels revolutionize retail pricing with wireless update capabilities and multi-year battery life. Digital signage applications leverage E-ink technology for outdoor displays with perfect daylight visibility. Transportation systems employ electronic paper for real-time schedule displays with minimal infrastructure requirements.

Rigid-flex PCB solutions enable innovative form factors including wraparound displays and curved reading devices pushing boundaries of traditional electronics.

E-ink PCB Manufacturing Cost and Lead Time

Highleap PCB Factory provides comprehensive E-ink PCB solutions from concept development through volume production, supporting global display manufacturers with rapid deployment and consistent quality.

Engineering Excellence:

Our technical team delivers power optimization analysis, signal integrity verification, and design-for-manufacturing reviews. Quick-turn prototyping within 48-72 hours accelerates product development cycles. Component selection guidance ensures optimal performance with available display technologies.

Manufacturing Capabilities:

Turnkey assembly services manage complete production including specialized E-ink components sourcing. Flexible production systems accommodate prototypes through millions of units annually. Advanced logistics ensure global delivery with appropriate packaging for sensitive display assemblies.

Quality Commitment:

• Rigorous testing protocols validate electrical parameters critical for display operation • Environmental testing confirms performance across temperature and humidity extremes • Long-term reliability testing simulates years of operation ensuring field performance • Complete traceability systems track materials and processes throughout production

Partnership with Highleap PCB Factory ensures access to specialized E-ink manufacturing expertise, advanced production capabilities, and commitment to quality that brings electronic paper innovations to market successfully. Our investment in technology and continuous improvement maintains leadership in specialized display PCB manufacturing supporting next-generation electronic paper applications.

Frequently Asked Questions About E-ink PCB

Q: What makes E-ink PCB manufacturing different from standard display PCBs?

A: E-ink PCBs require specialized low-power optimization, unique substrate compatibility, and high-voltage driving circuits. The manufacturing process accommodates flexible interconnections and temperature-sensitive components specific to electronic paper technology.

Q: How do you ensure long-term reliability for battery-powered E-ink devices?

A: We use strategic component selection to minimize power consumption, apply conformal coating for environmental protection, and conduct accelerated life testing to validate multi-year operation performance.

Q: What substrate materials work best for E-ink display applications?

A: Polyimide offers excellent flexibility for bendable displays, FR-4 provides cost-effectiveness for rigid applications, and high-TG materials ensure assembly compatibility. Selection depends on specific application requirements.

Q: Can you support both consumer and industrial E-ink applications?

A: Yes, we provide scalable solutions from compact e-reader boards to robust industrial designs. Our manufacturing capabilities accommodate all market segments with appropriate quality standards and testing protocols.