The evolution of electronic systems toward higher power densities and improved thermal management has driven significant innovation in extreme copper PCB technology. As power electronics continue to advance, the demand for printed circuit boards capable of handling substantial current loads while maintaining thermal stability has become critical across industries ranging from automotive to renewable energy systems.

If you're seeking a capable partner for high‑current PCB design and manufacturing, explore our full capabilities in PCB manufacturing.

Understanding Extreme Copper PCB Technology

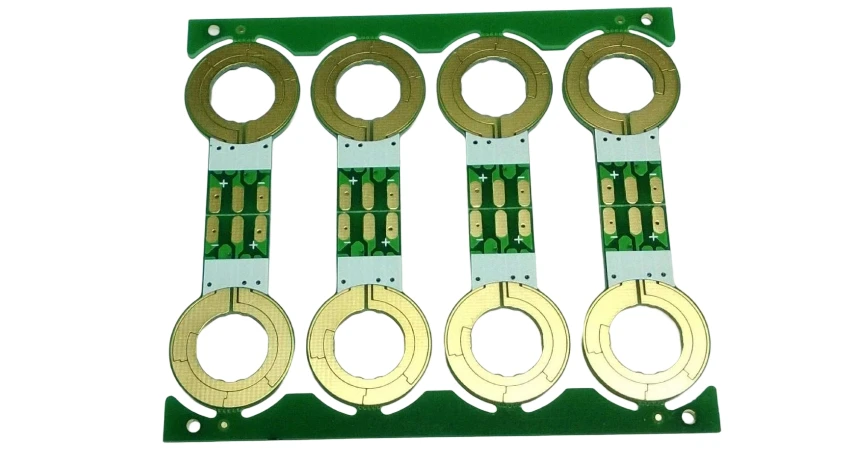

Extreme copper PCBs, also known as heavy copper printed circuit boards, represent a specialized category of circuit boards featuring copper thickness ranging from 3 oz to 30 oz (105 µm to 1050 µm), significantly exceeding the standard 1 oz (35 µm) copper weight found in conventional PCBs. This enhanced copper thickness enables superior current‑carrying capacity, improved thermal dissipation, and enhanced mechanical durability for demanding applications.

The manufacturing process for extreme copper PCBs requires sophisticated etching techniques and specialized equipment to achieve precise trace geometries while maintaining the structural integrity of thicker copper layers. Advanced electroplating processes ensure uniform copper distribution across the board, while controlled impedance considerations become increasingly complex with higher copper weights.

Critical Design Parameters and Guidelines

Based on industry standards and manufacturing capabilities, extreme copper PCB design follows specific parameters that ensure reliable performance. The relationship between copper thickness, minimum trace width, and current‑carrying capacity forms the foundation of effective design strategies.

For copper thicknesses ranging from 5 oz to 30 oz, minimum dielectric thickness requirements scale proportionally, typically requiring 0.90 mm to 1.08 mm for multilayer configurations. The minimum prepreg thickness increases from 0.15 mm at 5 oz to 1.03 mm at 30 oz copper weight, reflecting the mechanical stress considerations inherent in extreme copper applications.

Via design in extreme copper PCBs demands careful attention to aspect ratios and minimum hole sizes. Standard configurations maintain aspect ratios between 1:6 and 1:8, with minimum via diameters scaling from 0.6 mm for lighter copper weights to 1.3 mm for extreme thickness applications. This scaling ensures reliable plating coverage and mechanical stability throughout the PCB thickness.

Current‑Carrying Capacity Analysis

The current‑carrying capacity of extreme copper PCBs varies significantly based on copper weight, trace width, and thermal management considerations. For 1 oz copper at a 20 °C temperature rise, a 1.59 mm trace width can safely carry 4.6 A, while the same trace geometry with 30 oz copper can handle 88.1 A under identical thermal conditions.

This dramatic improvement in current handling capability makes extreme copper PCBs essential for high‑power applications including electric‑vehicle charging systems, renewable‑energy inverters, and industrial motor‑control circuits. The relationship between copper thickness and current capacity follows established thermal models, with heat dissipation becoming the primary limiting factor in high‑current applications.

Wide‑trace applications benefit significantly from extreme copper technology, with 406.4 mm trace widths in 30 oz copper configurations capable of handling nearly 3000 A under controlled thermal conditions. Such capabilities enable direct integration of power‑distribution systems within the PCB structure, eliminating external bus bars and reducing system complexity.

Thermal Management Considerations

Extreme copper PCBs excel in thermal‑management applications due to their enhanced heat‑spreading capabilities. The increased copper cross‑sectional area provides superior thermal conductivity, enabling effective heat distribution across the board surface. This characteristic proves particularly valuable in power electronics where component junction temperatures directly impact reliability and performance.

Thermal‑via design becomes critical in extreme copper applications, with via size and density calculations requiring careful optimization. The thermal resistance of copper‑filled vias decreases significantly with increased copper thickness, improving heat transfer from component‑mounting areas to heat sinks or thermal planes.

Design engineers must consider thermal expansion coefficients when implementing extreme copper PCBs, as the increased copper volume can create mechanical stress during temperature cycling. Proper copper balance across layers and strategic placement of thermal‑relief features help mitigate these effects while maintaining electrical performance.

Manufacturing Process Optimization

The production of extreme copper PCBs requires specialized manufacturing techniques that differ substantially from standard PCB processes. Controlled‑depth milling ensures precise copper‑thickness distribution, while advanced electroplating systems maintain uniform deposition across large panel sizes.

Etching processes for extreme copper applications utilize specialized chemistry and extended processing times to achieve the required trace geometries. Fine‑line etching capabilities become increasingly challenging with thicker copper, necessitating careful optimization of resist application and exposure parameters.

Quality‑control measures for extreme copper PCBs include comprehensive electrical testing, cross‑sectional analysis, and thermal characterization. These verification processes ensure that finished boards meet the stringent requirements of high‑power applications while maintaining long‑term reliability.

Application‑Specific Design Strategies

Power‑converter applications benefit from extreme copper PCBs through reduced resistance losses and improved thermal performance. Switching power supplies operating at high frequencies require careful consideration of skin‑effect and proximity‑effect losses, which can be mitigated through strategic copper distribution and trace‑geometry optimization.

Motor‑drive applications leverage extreme copper technology for gate‑drive circuits and power‑switching stages. The ability to integrate high‑current paths within the PCB structure simplifies assembly processes while improving thermal management and reducing electromagnetic interference.

Renewable‑energy systems, including solar inverters and wind‑power converters, utilize extreme copper PCBs for their superior current‑handling capabilities and enhanced reliability under harsh environmental conditions. The robust construction of extreme copper boards provides extended operational life in outdoor installations.

Advanced Design Methodologies

Signal‑integrity considerations in extreme copper PCB design require sophisticated modeling techniques to account for the altered electromagnetic properties of thicker copper traces. Impedance calculations must incorporate the modified trace geometry and increased copper thickness to maintain signal quality in high‑speed applications.

Power‑delivery network design benefits from the reduced resistance of extreme copper traces, enabling more efficient power distribution with lower voltage drop across the board. Strategic placement of power planes and optimization of via‑stitching patterns further enhance power‑delivery performance.

Electromagnetic‑compatibility (EMC) performance can be improved through proper implementation of extreme copper ground planes and shielding structures. The increased copper thickness provides superior shielding effectiveness while reducing ground impedance throughout the frequency spectrum.

Conclusion

Extreme copper PCB technology represents a critical enabling technology for modern high‑power electronic systems. Through careful consideration of design parameters, thermal‑management strategies, and manufacturing constraints, engineers can leverage the unique capabilities of extreme copper PCBs to achieve superior performance in demanding applications. As the technology continues to evolve, new possibilities for integration and optimization will emerge, further expanding the potential applications for these specialized circuit boards.

The successful implementation of extreme copper PCBs requires close collaboration between design engineers and manufacturing partners to ensure optimal results. At Highleap PCB, our expertise in extreme‑copper manufacturing processes enables the realization of complex designs while maintaining the highest quality standards for critical applications.