Highleap PCB Factory delivers advanced flexible display PCB manufacturing for next-generation bendable screens, foldable devices, and conformable display applications. Our expertise spans flexible OLED circuit fabrication, ultra-thin substrate processing, and precision assembly enabling revolutionary display form factors. From foldable smartphones to rollable televisions, we provide manufacturing excellence for flexible display innovations.

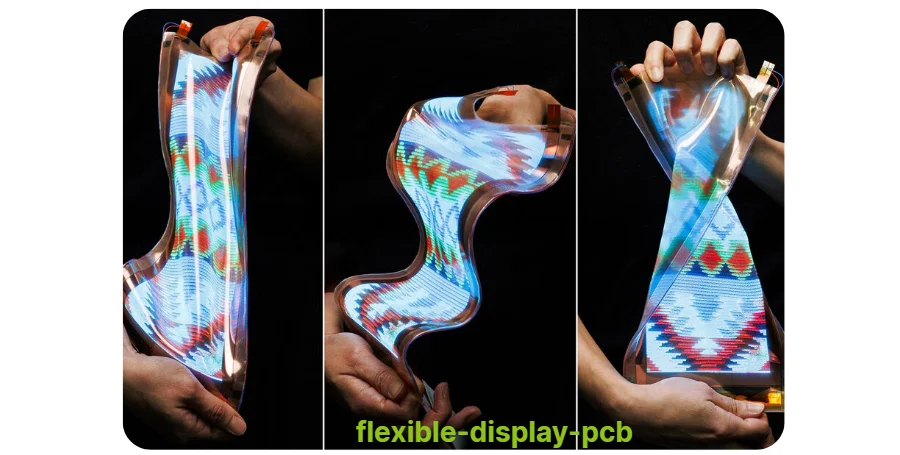

Flexible display PCB technology transforms how we interact with electronic devices, enabling unprecedented form factors and user experiences. These specialized circuits maintain electrical performance through repeated flexing while supporting high-resolution displays with exceptional color accuracy. Highleap PCB Factory combines cutting-edge flexible circuit capabilities with display technology expertise delivering bendable display PCBs meeting demanding performance requirements.

Flexible OLED PCB Design Guidelines

Modern flexible display PCB design demands exceptional mechanical durability while maintaining signal integrity through dynamic flexing conditions. Bendable OLED circuits integrate display drivers, touch sensors, and power management on substrates surviving millions of flex cycles without performance degradation.

Core Technical Specifications:

• Substrate Materials: Polyimide, LCP, and ultra-thin glass for different flexibility requirements • Bend Radius: Designs supporting 1-5mm radius for tight folding applications • Flex Endurance: 200,000+ cycles at specified bend radius without failure • Layer Count: 2-6 layer flexible constructions with embedded components

High-frequency PCB materials maintain signal quality for high-speed display interfaces while providing mechanical flexibility. Advanced adhesive systems ensure layer stability through repeated flexing maintaining reliable interconnections.

Critical Design Factors:

Stress distribution analysis optimizes trace routing through bend areas minimizing fatigue failures. Neutral bend axis positioning reduces copper strain during flexing. Stiffener placement provides mechanical support for component areas while maintaining overall flexibility. Ground plane design ensures electromagnetic compatibility without compromising mechanical properties.

Bendable Display PCB Materials Selection

Flexible display PCB manufacturing employs specialized equipment and processes handling delicate substrates while achieving fine geometries essential for high-resolution displays.

Advanced Processing Technologies:

Roll-to-roll processing enables efficient production of large-area flexible circuits. Laser direct imaging achieves sub-50μm features on dimensionally unstable substrates. Plasma treatment enhances adhesion for subsequent metallization and assembly processes.

Precision Manufacturing:

• Material Handling: Specialized fixtures preventing substrate damage during processing • Via Formation: Laser drilling for microvias preserving substrate integrity • Plating Processes: Additive and semi-additive techniques for fine traces • Surface Treatment: Chemical processes optimized for flexible materials

Multilayer PCB techniques adapted for flexible substrates enable complex routing in minimal thickness. Controlled lamination processes ensure consistent adhesion without compromising flexibility.

Flexible Screen Circuit Board Manufacturing Process

Flexible display PCB assembly requires specialized techniques accommodating substrate movement while ensuring reliable component attachment surviving mechanical stress.

Advanced Assembly Capabilities:

Low-temperature soldering processes prevent substrate damage while ensuring reliable joints. Anisotropic conductive adhesives enable ultra-fine pitch connections for display drivers. Underfill materials provide mechanical reinforcement without restricting flexibility.

Component Integration:

• Display Driver ICs: Chip-on-flex bonding for direct display connection • Touch Controllers: Integration with transparent conductive layers • Power Management: Miniaturized components minimizing thickness • Interconnections: Zero insertion force connectors for reliable mating

SMT assembly adapted for flexible substrates includes specialized fixtures maintaining planarity during placement and reflow. Selective reinforcement protects critical components while preserving overall flexibility.

Environmental protection through thin conformal coatings shields assemblies from moisture without adding stiffness. Comprehensive testing validates mechanical and electrical performance through flex cycling and environmental exposure.

Foldable Display PCB Applications and Markets

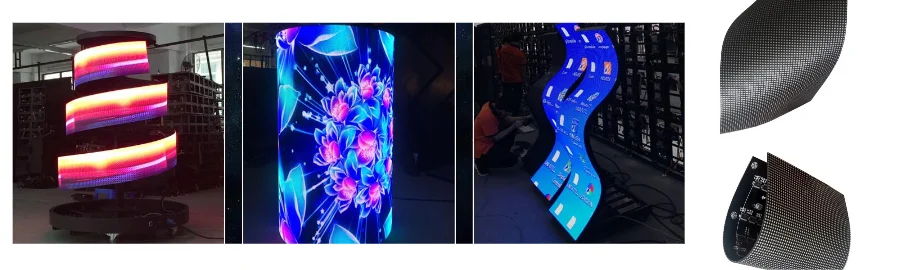

Flexible display PCBs enable transformative products across consumer, automotive, and medical markets with innovative form factors impossible with rigid displays.

Consumer Electronics:

Foldable smartphones combine portability with large screen experiences through sophisticated hinge mechanisms and flexible displays. Wearable devices integrate conformal displays wrapping around wrists or clothing. Rollable tablets and laptops maximize screen area while minimizing device footprint when stored.

Automotive Integration:

Curved automotive displays seamlessly integrate with dashboard contours enhancing aesthetic appeal and ergonomics. Pillar-to-pillar displays create immersive cockpit experiences. Flexible lighting solutions enable dynamic exterior styling and advanced safety features.

Medical and Industrial:

Conformal medical patches integrate displays with physiological monitoring for real-time health tracking. Industrial equipment employs flexible displays conforming to control surfaces improving operator interfaces. Aerospace applications leverage lightweight flexible displays reducing system weight.

Flexible Display PCB Testing and Quality Control

Highleap PCB Factory provides end-to-end flexible display PCB solutions from design optimization through high-volume production, supporting global manufacturers with advanced capabilities and proven reliability.

Engineering Support:

• Mechanical simulation predicts flex behavior optimizing designs for reliability • Signal integrity analysis ensures performance through dynamic conditions • Design reviews identify potential issues before production • Rapid prototyping accelerates development cycles with quick-turn capabilities

Production Capabilities:

Small batch assembly services support development and pilot production. Scalable manufacturing systems accommodate volume requirements from hundreds to millions annually. Advanced quality systems ensure consistent production across all volumes.

Quality Assurance:

Dynamic flex testing validates mechanical endurance under application conditions. Environmental testing confirms performance across temperature and humidity ranges. Electrical testing verifies signal integrity and power consumption specifications. Statistical process control maintains consistent quality throughout production.

Supply Chain Excellence:

Strategic material sourcing ensures availability of specialized flexible substrates. Component procurement leverages global networks for optimal pricing and availability. Logistics capabilities include specialized packaging protecting flexible assemblies during shipment. International shipping expertise ensures timely delivery worldwide.

Partnership with Highleap PCB Factory provides access to specialized flexible display manufacturing expertise, advanced production technologies, and commitment to quality bringing innovative display products to market successfully. Continuous investment in capabilities and training maintains leadership in flexible display PCB manufacturing supporting next-generation bendable display applications.

Frequently Asked Questions About Flexible Display PCB

Q: What determines the minimum bend radius for flexible display PCBs?

A: Minimum bend radius depends on copper thickness, substrate material, and layer count. Single-layer polyimide achieves 1mm radius while multilayer requires 3-5mm for reliable performance.

Q: How do you ensure reliability through millions of flex cycles?

A: We use rolled annealed copper for fatigue resistance, optimize trace routing to minimize stress, and conduct accelerated testing to validate long-term reliability.

Q: What assembly challenges exist for flexible display PCBs?

A: Main challenges include substrate dimensional instability, low-temperature processing requirements, and component placement accuracy. We address these with specialized fixtures and vision systems.

Q: Can you support both prototype and mass production requirements?

A: Yes, we offer 48-hour rapid prototyping for validation and scalable production up to millions of units annually with consistent quality across all volumes.