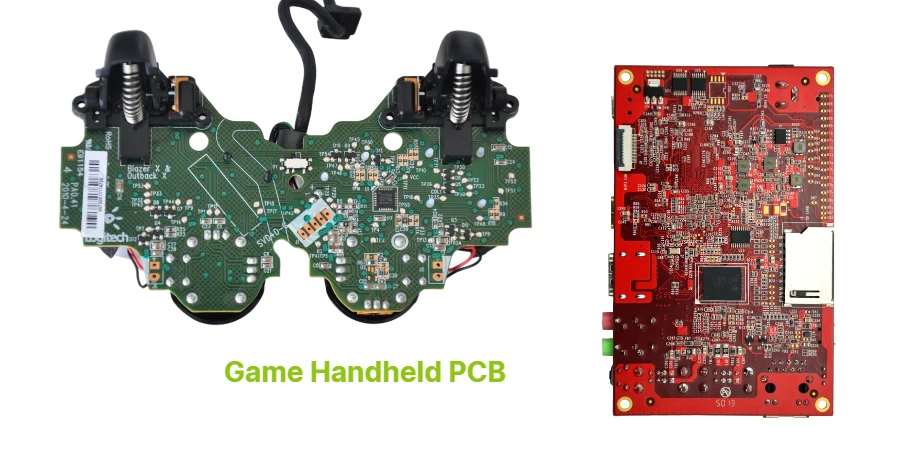

From nostalgic retro consoles that revive childhood memories to today’s sleek portable arcade systems, handheld gaming has always depended on the technology inside its circuit boards. HILPCB designs and manufactures Game Handheld PCBs that bring these devices to life—integrating display control, audio processing, input circuitry, power management, and wireless connectivity into compact, reliable boards. Whether for hobbyist builds, indie gaming projects, or commercial handheld consoles, we provide both the engineering expertise and full turnkey assembly needed to deliver an exceptional gaming experience.

Game Handheld PCB Core Architecture

Modern Game Handheld PCB designs integrate multiple gaming subsystems for optimal portable entertainment:

Processing & Control:

- ARM-based microcontrollers for Portable Game PCB emulation and native gaming

- Graphics processing units optimized for LCD/OLED display output

- Real-time operating system support for multi-game platforms

- Memory controllers for ROM/RAM management and save state functionality

Input & Output Systems:

- Button matrix controllers for D-pad, action buttons, and shoulder triggers

- Analog stick interfaces with precision ADC conversion

- Audio processing circuits with amplifiers and headphone output

- Display controllers supporting various LCD and OLED screen formats

Power & Connectivity:

- Battery management systems for rechargeable lithium cells

- USB charging circuits with power delivery optimization

- WiFi and Bluetooth modules for multiplayer and content sharing

- SD card interfaces for game storage and homebrew development

Professional Retro Gaming PCB designs typically utilize 4-6 layer multilayer PCB structures to manage complex signal routing between processors, displays, and input systems while maintaining compact form factors essential for portable gaming comfort.

Manufacturing Excellence for Gaming Hardware

Our production capabilities cater specifically to Game Handheld PCB requirements:

Precision Manufacturing:

- Handheld Console PCB production using FR4 PCB materials optimized for gaming applications

- High-density component placement for Gaming Device PCB miniaturization

- Advanced signal integrity management for interference-free gaming performance

Assembly Capabilities: SMT assembly lines handle precision placement of gaming processors, display controllers, and input interface components. Our turnkey assembly services include firmware installation, display calibration, and comprehensive gaming performance testing.

Prototyping Support:

- Rapid prototyping for DIY Gaming PCB projects and maker community

- Small batch assembly for indie game developers and limited edition consoles

- Design optimization for cost-effective small-scale production

Advanced Gaming Technology Integration

Display Technology: Game Handheld PCB systems support various display technologies including IPS LCD, OLED, and e-ink displays. Our designs utilize HDI PCB technology for ultra-compact display connector integration while maintaining signal integrity for high-refresh gaming.

Audio Processing: High-quality audio is essential for gaming immersion. We implement dedicated audio processing circuits with low-noise amplifiers and support for stereo speakers and headphone outputs, ensuring crystal-clear game audio and sound effects.

Input Interface Design: Gaming controls require responsive and durable input systems. Our Portable Game PCB designs incorporate:

- Tactile membrane switches for reliable button response

- Analog joystick interfaces with precision calibration

- Touch panel integration for modern gaming interfaces

- Haptic feedback controllers for enhanced gaming experience

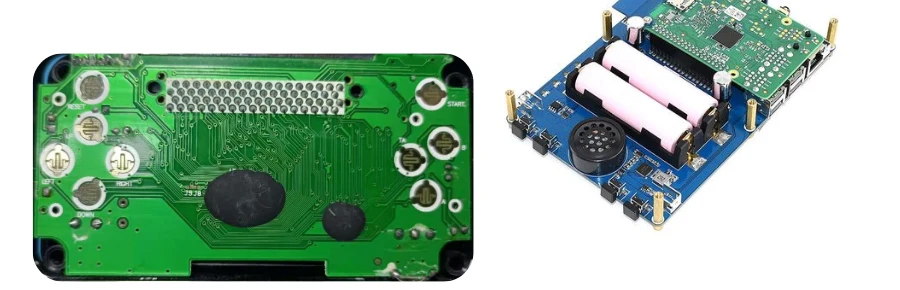

Flexible Interconnections: Complex handheld designs benefit from flex PCB solutions for button panels, display connections, and battery interconnects, enabling ergonomic designs while maintaining electrical reliability.

Gaming Applications & Market Segments

Our Game Handheld PCB solutions serve diverse gaming markets:

Retro Gaming:

- Classic arcade emulation consoles

- Multi-system retro gaming devices

- Portable versions of vintage game systems

- Open-source gaming platforms like RetroPie handhelds

Modern Gaming:

- Independent gaming consoles for indie developers

- Educational gaming devices for STEM learning

- Specialized gaming controllers and accessories

- Custom gaming solutions for unique applications

DIY & Maker Community:

- Open hardware gaming platforms

- Raspberry Pi-based gaming projects

- Arduino gaming shields and expansion boards

- Custom PCB designs for gaming enthusiasts

Commercial Applications:

- Promotional gaming devices for marketing

- Training simulators with game-like interfaces

- Therapeutic gaming devices for rehabilitation

- Industrial control panels with gaming-inspired interfaces

Why Choose HILPCB for Game Handheld PCB Manufacturing

At HILPCB, we combine over 15 years of PCB manufacturing expertise with deep knowledge of gaming hardware requirements. From retro consoles to modern handhelds, we understand that performance, durability, and player experience are critical. Our engineers specialize in ARM-based processors, display drivers, audio systems, and high-speed interconnects, ensuring your Game Handheld PCB meets the exact performance standards that gamers expect.

We support projects of all scales — from prototypes for indie developers and DIY makers to mass production for global gaming brands. With flexible MOQs starting at just 5 units, rapid prototyping in as fast as 48–72 hours, and full turnkey assembly including component sourcing, firmware programming, and functional testing, we help you move from concept to launch without delays. Every board is built to IPC-A-610 Class 3 standards and tested under gaming stress conditions, ensuring long-term reliability in real-world usage.

Partnering with HILPCB means gaining an innovation ally. We provide design-for-manufacturing (DFM) guidance, suggest the latest gaming technologies, and optimize layouts for size, power efficiency, and signal integrity. Whether you need a compact portable arcade PCB, a high-performance OLED-based gaming device, or a custom controller board, we help you deliver products that stand out in the competitive gaming market.

Frequently Asked Questions

Q: What makes Game Handheld PCB design unique compared to other consumer electronics?

A: Game Handheld PCB design requires balancing performance, power efficiency, and portability. Key challenges include managing multiple high-speed interfaces (display, audio, input) while maintaining low power consumption for extended battery life. Gaming applications also demand low-latency input processing and stable performance under varying thermal conditions.

Q: Can you support small-scale production for indie game developers?

A: Yes, we specialize in supporting indie developers and maker projects. Our small batch assembly capabilities start from prototype quantities, and we provide design optimization services to help reduce costs for small-scale production runs while maintaining gaming performance standards.

Q: What display technologies do you support for handheld gaming devices?

A: Our Game Handheld PCB designs support various display technologies including IPS LCD (2.8" to 7"), OLED displays for premium devices, and e-ink displays for low-power gaming applications. We handle the complex signal routing and power management required for each display type.

Q: How do you ensure gaming performance and user experience?

A: We focus on low-latency design, stable power delivery, and thermal management. Our Game Handheld PCBs undergo extensive gaming performance testing including input responsiveness, display quality, audio fidelity, and battery life validation to ensure optimal gaming experience across various game types and usage scenarios.