When a next-generation 5G base station fails its first compliance test, the culprit is often not the chipset or the software—it’s the PCB. Impedance mismatches create standing waves, reflections, and unwanted harmonics that cripple RF and microwave performance. For high-frequency designs, precise impedance control is not optional; it’s the foundation of reliable operation and regulatory compliance.

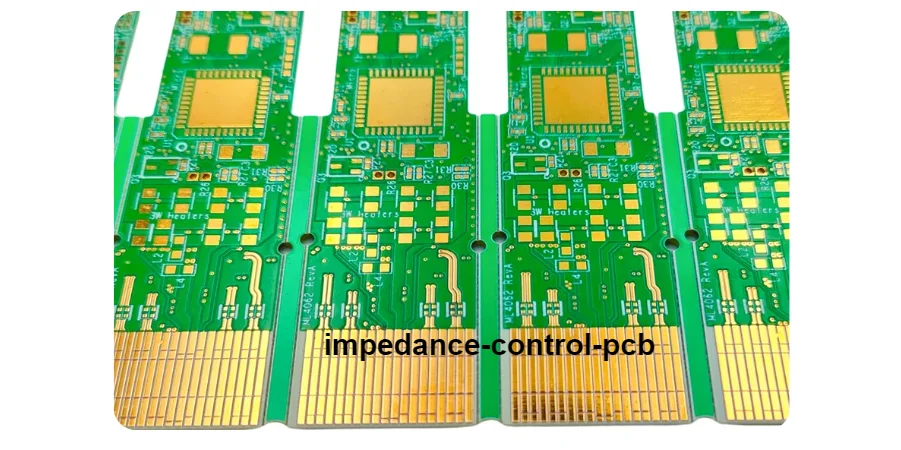

At Highleap PCB Factory (HILPCB), we specialize in RF and microwave PCB manufacturing with ±5Ω impedance accuracy. Our engineering process eliminates variability before your design reaches the test bench, ensuring optimal signal integrity for 5G, aerospace, defense, and other critical applications.

The Physics Behind Impedance Control

Understanding impedance control starts with recognizing that every PCB trace behaves as a transmission line at frequencies where signal wavelengths approach trace dimensions. For modern digital systems operating at multi-gigahertz frequencies, even short traces exhibit transmission line behavior requiring careful impedance management.

Characteristic Impedance Fundamentals: The relationship between trace geometry and impedance follows well-established electromagnetic principles. For microstrip traces, characteristic impedance depends on trace width, copper thickness, substrate height, and dielectric constant. Small variations in any parameter can significantly impact the final impedance value, making manufacturing control essential for consistent results.

Material Properties Impact: PCB substrate materials exhibit frequency-dependent dielectric properties that affect impedance stability across operating bandwidths. Standard FR4 materials provide adequate performance for applications below 5GHz, while specialized low-loss materials become necessary for millimeter-wave applications. Our material selection process considers both electrical performance and manufacturing compatibility.

Temperature Coefficient Effects: Impedance stability across temperature ranges depends on thermal expansion characteristics of both substrate and copper conductors. High-Tg PCB materials provide better dimensional stability, while proper thermal management prevents impedance drift during operation.

Manufacturing Process Excellence in Impedance Control

Achieving precise and consistent impedance control in PCB manufacturing requires a streamlined, integrated process that ensures every variable is meticulously monitored and controlled. This is critical for applications in high-frequency designs, where even minor discrepancies can lead to signal integrity issues.

Key Manufacturing Techniques for Impedance Control

We implement a combination of advanced processes and cutting-edge technologies to guarantee precise impedance control across every PCB we manufacture.

1. Statistical Process Control (SPC)

To maintain strict impedance tolerances, we employ Statistical Process Control (SPC) systems that continuously monitor critical variables such as trace width, copper thickness, and dielectric height throughout the entire production cycle. By leveraging real-time data collection, we can make immediate adjustments during manufacturing, ensuring that impedance stays within the required ±5% specifications.

- Real-Time Monitoring: Constantly updates our process parameters to maintain stability.

- Immediate Adjustments: Allows for instant corrections if any variance is detected.

- Minimizes Waste: Ensures optimal usage of materials by maintaining process consistency.

2. Advanced Copper Plating Control

The electroplating process plays a vital role in ensuring uniform trace resistance and impedance characteristics. We utilize state-of-the-art automated plating systems, which incorporate current density optimization and real-time thickness monitoring to ensure uniform copper distribution, even in complex HDI PCB designs with high aspect ratio vias.

- Automated Plating Systems: Improve plating uniformity and efficiency.

- Thickness Monitoring: Ensures the copper distribution is consistent across the entire PCB.

- HDI PCB Compatibility: Our process accommodates intricate designs with high-density interconnects.

3. Precision Etching for Accurate Impedance

The etching process is crucial for achieving the precise trace width required for impedance control. Our advanced precision etching techniques use real-time monitoring of etch rate uniformity, with automatic chemistry adjustments to guarantee a consistent trace profile across the entire panel. This meticulous control ensures that the final impedance is highly accurate, reducing the risk of signal interference and data loss.

- Trace Width Control: Guarantees accurate impedance characteristics throughout the board.

- Automated Chemistry Adjustments: Allows for optimal etching, even in complex designs.

- Improved Signal Integrity: Precision in etching leads to enhanced electrical performance in high-speed applications.

High-Speed Digital System Applications

Modern processors and communication systems push frequency boundaries that make impedance control critical for basic functionality, not just optimal performance.

Processor Interface Design: Next-generation CPUs operate at clock frequencies approaching 10GHz with edge rates in the sub-100 picosecond range. At these speeds, every trace behaves as a transmission line where impedance mismatches cause reflections that can corrupt data or create timing violations. DDR5 memory interfaces exemplify this challenge, requiring 50Ω single-ended impedance control within ±7% to maintain timing margins across all operating conditions.

SerDes Channel Optimization: Multi-gigabit serial interfaces like 25G/100G Ethernet and PCIe Gen 5 use advanced signaling techniques that demand exceptional impedance accuracy. Channel equalization and forward error correction can compensate for some channel impairments, but consistent impedance provides the foundation for reliable high-speed communication.

Power Delivery Network Integration: High-performance processors require sophisticated power delivery systems that must coexist with sensitive high-speed signals. Power plane impedance affects signal integrity through ground bounce and simultaneous switching noise. Our multilayer PCB stackup designs optimize both signal impedance and power delivery impedance for maximum system performance.

RF & Microwave PCB Engineering for Optimal Signal Integrity

RF and microwave PCB design demands the most stringent impedance control, as even minor deviations can cause measurable loss, reflection, and distortion.

50Ω System Integrity

The industry-standard 50Ω impedance offers the optimal balance between power handling and attenuation. Achieving this consistently requires precise control over trace dimensions, dielectric properties, and fabrication tolerances. Our processes maintain ±2Ω accuracy across varied stack-ups, ensuring maximum power transfer and signal fidelity.

Optimized Transmission Line Topologies

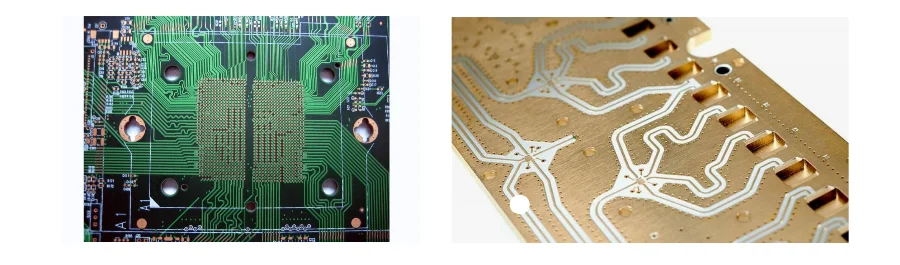

Common RF geometries include microstrip, stripline, and coplanar waveguide:

- Microstrip – Simplifies component access and tuning.

- Stripline – Offers superior isolation within multilayer structures.

- Coplanar Waveguide – Provides stable impedance with adjacent ground references.

**Controlled Via Transitions **

Layer changes introduce inductive and capacitive discontinuities that degrade RF performance. We employ impedance modeling, stub elimination via back-drilling, and optimized pad/via geometry to minimize insertion loss and reflections.

Precision Connector Interfaces

From PCB trace to coaxial interface, impedance continuity is critical. Our connector footprint engineering ensures matched impedance, minimal parasitics, and mechanical robustness for repeatable high-frequency performance.

HILPCB — Precision Impedance-Controlled PCB Solutions

1. Our Core

We specialize in high-frequency, high-speed, and complex multilayer impedance-controlled PCB manufacturing, offering a fully integrated process from early design verification to mass production. Our expertise covers advanced RF and microwave systems, high-speed digital interconnects, and dense multilayer stackups with tight impedance tolerances. Every board we produce is engineered to meet target impedance values with proven long-term stability, even under the most demanding operating conditions.

2. Our Capabilities

- Time Domain Reflectometry (DC–40 GHz) — Pinpointing localized impedance deviations with calibration traceable to national standards.

- Vector Network Analyzer S-Parameter Analysis — Validating insertion loss, return loss, and impedance stability across wide frequency ranges.

- Production-Matched Test Coupons — Replicating actual stackup and trace geometries to ensure true-to-production performance data.

- High-Precision SMT Assembly — Micron-level component placement for optimal high-frequency signal integrity.

- Rigid-Flex PCB Technology — Extending precise impedance control into complex three-dimensional assemblies.

3. Why Choose HILPCB

- End-to-End Quality Control — All processes, from material selection to final assembly, are managed in-house for complete oversight.

- Rapid Prototyping to Volume Production — Flexible scaling without compromising precision or consistency.

- Proven Industry Expertise — Successfully delivering solutions for telecommunications, aerospace, medical devices, and high-performance computing applications.

From the first prototype to full-scale production, we ensure your high-speed designs achieve precise impedance targets — consistently, reliably, and without costly iterations. Our engineering team is ready to help you transform complex requirements into manufacturable, high-performance solutions.

Frequently Asked Questions

Q: What impedance tolerance can you achieve in production? We routinely achieve ±5% impedance tolerance for standard applications, with ±2Ω capability for critical RF applications through advanced process control and premium material selection.

Q: How do you validate impedance control during manufacturing? Every production panel includes impedance test coupons measured using calibrated TDR equipment, with complete documentation provided for traceability and quality assurance.

Q: Can impedance be controlled on flexible PCBs? Yes, flex PCB designs can achieve controlled impedance using specialized flexible dielectric materials and precise conductor geometry control.

Q: What's the impact of temperature on impedance stability? Material selection significantly affects temperature stability. Standard FR4 shows ~3% impedance change over automotive temperature ranges, while specialized materials provide better stability for critical applications.

Q: How early should impedance requirements be established? Impedance requirements should be defined during initial stackup design to ensure manufacturable solutions and prevent costly design revisions.

Q: What test methods validate impedance accuracy? We use both TDR and network analyzer measurements on production test coupons to validate impedance performance and characterize frequency response across your operating bandwidth.