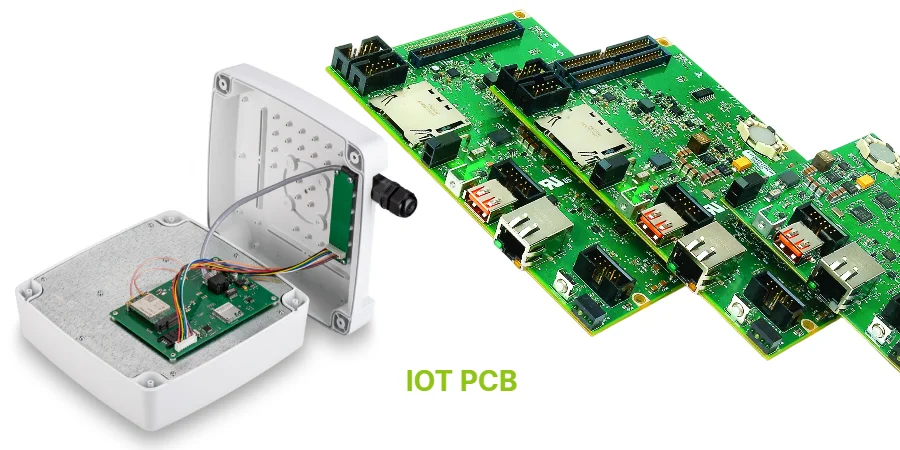

Highleap PCB Factory manufactures IOT PCB solutions for connected devices across consumer, industrial, medical, and automotive markets. We focus on complex stackups, special materials, and tight process control—so your designs meet targets for RF performance, low power, and long-term reliability. From IoT gateway PCBs and smart sensor PCBs to battery-powered IoT boards and edge computing PCBs, our team builds what you specify, at the quality level you expect.

We support the full lifecycle: DFM review, quick-turn prototypes, volume scaling, and after-sales support. Payment is straightforward, and logistics are global and predictable.

IOT PCB Design Guidelines

IOT devices compress radios, sensors, power, and compute into small footprints. Good layout and materials selection are as critical as component choice.

Core Technical Specifications:

• Layer Count: 4–12L HDI (stacked/skip microvias) for dense RF + MCU + PMIC integration

• Impedance Control: ±5% for 2.4/5/6 GHz RF, NB-IoT/LTE-M, Sub-GHz ISM links

• Power Profile: Low-leakage planes, tight ground returns, sleep-current optimization

• Thermal Strategy: Via-in-pad, thermal vias, and metal-core where heat density is high

Critical Design Factors:

- RF sections isolated with controlled-impedance routing, stitching vias, and clean reference planes.

- Clock and high-speed buses length-matched; return paths kept short to minimize EMI.

- Power trees segmented for radio, sensor, and compute domains to protect sleep currents.

- DFM rules aligned early via our Gerber Viewer and online 3D Viewer.

Materials and Stackups for IOT Applications

Special materials are often the difference between “works” and “works everywhere.” We build to spec and advise when trade-offs appear.

Specialized Materials We Process:

• High-TG FR-4 for robust lead-free assembly and thermal margin

• PTFE/Rogers/low-Dk laminates for high-frequency IoT PCB and antenna performance

• Polyimide flex / rigid-flex for wearables, compact modules, and connectors under motion

• Aluminum/Copper metal-core for LED drivers, power stages, and hot-spot control (Metal-Core PCB details)

• Ceramic (Al₂O₃/AlN) options on request for extreme thermal conductivity

Precision Manufacturing:

• Microvias (laser), stacked/any-layer as required

• Fine lines/space to 60/60 µm (design-dependent)

• ENIG/ENEPIG/OSP finishes for reliability and bonding flexibility

• Tight dielectric control for antenna and filter sections

IOT PCB Assembly Process

We assemble IoT device PCBs with consistent quality—0402/0201 passives, fine-pitch QFN/BGA, RF cans, modules, and connectors.

Advanced Assembly Capabilities:

• High-precision SMT assembly with AOI + X-ray for hidden joints

• Via-in-pad fill/planarization compatible with fine-pitch BGAs

• Low-voiding thermal pad processes for PMICs and RF PAs

• Conformal coating/underfill where environment or vibration demands it

(Need small runs before ramp?) Prototype to pilot is covered; see our full list of capabilities at Products & Services.

Integration Examples:

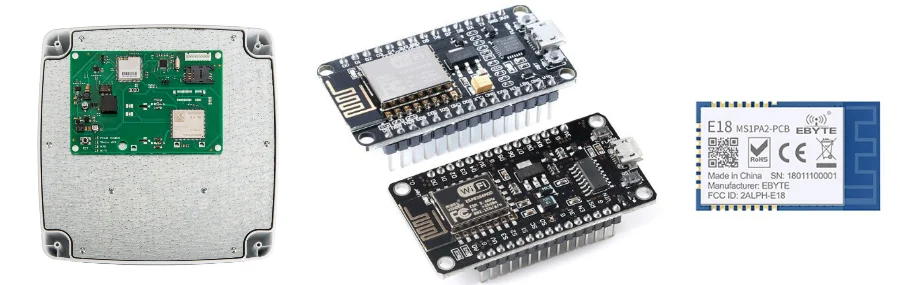

• IoT wireless module PCB: Wi-Fi/BLE/Zigbee/Thread/LoRa/NB-IoT with matched networks

• Sensor fusion boards: IMU/pressure/gas/optical with low-noise analog front-ends

• IoT gateway PCB: Ethernet, cellular, GNSS, secure element, and edge compute

Applications and Markets

Consumer & Smart Home – Smart thermostats, smart door locks, voice assistants, smart lighting, security cameras, environmental sensors, smart home hubs, home automation systems, energy management devices, connected appliances, smart displays, and remote control systems.

Industrial IoT (IIoT) – Condition monitoring systems, predictive maintenance solutions, asset tracking devices, smart meters, industrial robots, factory automation, environmental monitoring, real-time data acquisition, smart sensors for manufacturing, remote monitoring systems, supply chain management, and logistics tracking systems.

Healthcare & Wearables – Fitness trackers, health monitoring bands, ECG monitors, smartwatches, remote patient monitoring devices, biometric measurement devices, medical diagnostics tools, wearable glucose monitors, heart rate monitors, wearable sleep trackers, and personal health devices.

Mobility/Automotive – Telematics systems, GPS navigation, autonomous vehicle sensors, battery management systems (BMS), electric vehicle charging stations, vehicle-to-vehicle (V2V) communication, in-vehicle infotainment systems, smart lighting control, connected car applications, collision detection systems, fleet management systems, and intelligent transport systems (ITS).

Testing, Quality, and Reliability

Every batch is built to be deployed, not just demonstrated.

Engineering Support:

• DFM/DFT reviews, stackup proposals, and material risk notes

• Power profiling and SI/PI guidance for low-power IoT PCB design

• Quick-turn prototypes to validate RF, EMC, and power targets

Quality Systems:

• ICT/FCT where fixtures are available; boundary scan as needed

• Impedance coupons and RF coupon options for antenna sections

• Environmental testing (temp/humidity), vibration, salt-spray on request

Assurance, Service, and Logistics:

- Quality guarantee: root-cause analysis and corrective action if issues occur.

- After-sales support: responsive FA, rework/replace paths defined up front.

- Payment: flexible terms and methods to fit procurement flows.

- Shipping: export-ready docs, protective packaging, and global lanes with predictable lead times.

IOT PCB Manufacturing Support and After-Sales Service

At Highleap PCB Factory, we don't just deliver IOT PCB solutions; we ensure that you have ongoing support throughout the lifecycle of your product. Whether you need design-for-manufacturing feedback or rapid prototyping, we’re here to help. Additionally, our reliable after-sales service guarantees that your products perform as expected.

Comprehensive Support and Service:

• Design for Manufacturability (DFM) Reviews: Early validation to optimize your design for production

• Quick-Turn Prototyping: Test and validate your design quickly with fast turnaround times

• Flexible Payment Options: Easy and secure payment methods tailored to your needs

• Global Logistics: Seamless delivery worldwide, with custom packaging for sensitive products

We are committed to delivering products that meet your standards, on time, and with consistent quality.

Frequently Asked Questions About IOT PCB

Q: Can you handle both standard and special-material IoT boards?

A: Yes. We routinely build FR-4 HDI, PTFE/Rogers RF, rigid-flex polyimide, and metal-core IoT PCB for power-dense designs.

Q: What’s the best way to avoid RF surprises late in the project?

A: Lock stackup and impedance early, isolate RF from noisy domains, and validate with our Gerber Viewer and 3D Viewer before release.

Q: Do you support small pilot runs before mass production?

A: Absolutely—quick-turn prototypes, IoT PCB assembly for pilots, then scale to volume with the same process controls.

Q: Can you also build PCBs for non-IoT electronics?

A: Yes. We manufacture and assemble PCBs for IoT devices and any electronic product PCB categories—consumer, industrial, medical, and automotive—using the same quality framework.