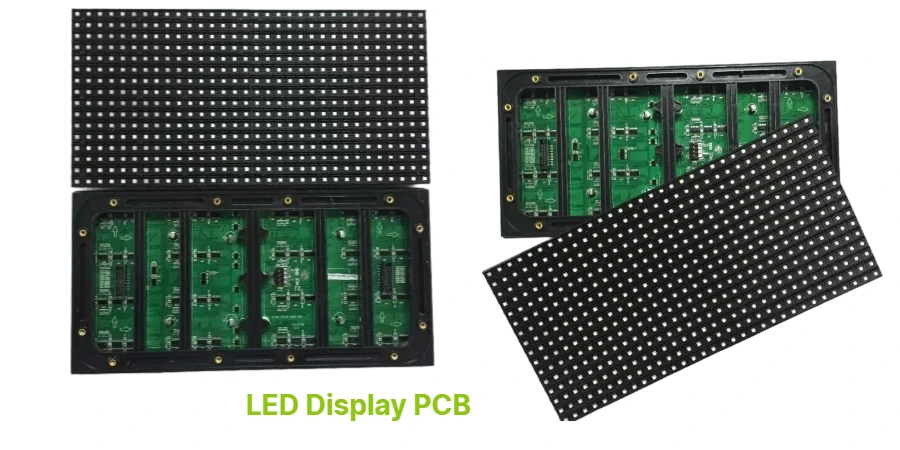

LED displays dominate outdoor advertising, sports stadiums, and high-brightness applications where visibility and impact matter most. Behind every brilliant LED display is a carefully engineered LED Display PCB managing massive power loads, precise timing, and environmental challenges that exceed conventional electronics requirements.

HILPCB specializes in LED Display PCB manufacturing for outdoor advertising, stadium installations, digital signage, and transportation displays. Our high-power PCB solutions handle the unique requirements of LED matrix systems, from current regulation to thermal management in demanding environments.

LED Display PCB designs integrate high-current drivers, switching power supplies, communication interfaces, and environmental protection within robust form factors. Our expertise encompasses small-pitch indoor modules, large-format outdoor displays, and specialized applications including transparent LED systems and architectural lighting.

LED Display PCB Architecture and Current Management

LED Display PCB design requires specialized knowledge of high-current distribution, thermal management, and electromagnetic compatibility. The fundamental challenge lies in delivering precise current control to thousands of LEDs while managing heat generation and maintaining synchronized operation across large installations.

Core LED Display PCB Components:

• High-Current LED Drivers: Constant-current regulation circuits managing individual LED chains with 16-bit PWM control for smooth dimming and color accuracy across wide brightness ranges

• Switching Power Systems: High-efficiency power supplies delivering multiple voltage rails from 3.3V logic to 5V LED supplies with current capacity exceeding 50 amperes per module

• Communication Controllers: High-speed data interfaces supporting Ethernet, fiber optic, and proprietary protocols for synchronized operation across massive display installations

• Environmental Protection: Ruggedized circuits with enhanced ESD protection, surge suppression, and moisture resistance meeting IP65/IP67 requirements for outdoor operation

LED Display PCBs must handle pixel refresh rates exceeding 3,840Hz to prevent flicker on camera while maintaining color uniformity across temperature variations. Our designs implement advanced current feedback control and temperature compensation ensuring consistent performance across environmental conditions.

We manufacture complete LED display ecosystems including LED display driver PCBs optimized for specific pixel pitches, LED display controller boards managing video processing, LED power supply modules with high-efficiency regulation, LED display hub cards for centralized control, and LED display calibration systems ensuring uniformity.

High-Power LED Display PCB Manufacturing

Professional LED Display PCB manufacturing employs specialized techniques for high-current handling, thermal management, and environmental durability. Material selection and process control directly impact LED lifespan, brightness uniformity, and system reliability in demanding outdoor applications.

Heavy Copper PCB Construction:

LED Display PCBs require 2-6 oz copper thickness for reliable current distribution. Our specialized electroplating processes ensure uniform copper deposition and current-carrying capacity while maintaining precise trace geometries for controlled impedance signals.

Thermal Management Solutions:

Aluminum PCB substrates with thermal conductivity up to 3.0 W/mK efficiently transfer heat from high-power LEDs to external heat sinks. These metal-core constructions prevent thermal buildup that degrades LED efficiency and lifespan.

Advanced Manufacturing Techniques:

• Heavy Copper Processing: Specialized plating and etching processes for 2-6 oz copper with controlled aspect ratios and reliable current distribution

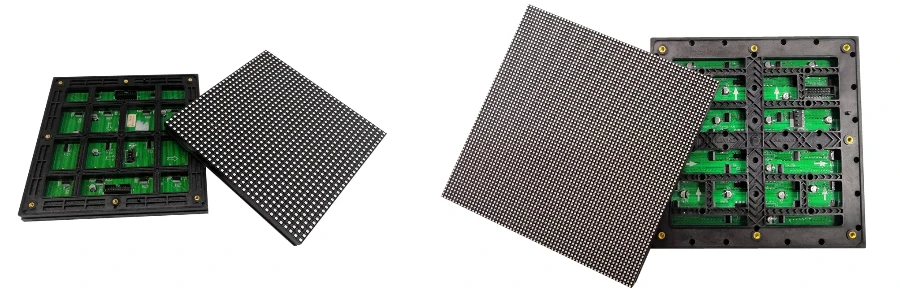

• Large Format Capability: PCB manufacturing up to 500mm x 500mm for large LED modules while maintaining dimensional accuracy and electrical performance

• Environmental Protection: Conformal coatings, potting compound compatibility, and corrosion-resistant finishes for outdoor installation requirements

• High-Voltage Isolation: Proper creepage and clearance distances for power supply sections with enhanced electrical safety and regulatory compliance

Professional LED Display PCB Assembly and Validation

LED Display PCB assembly requires specialized techniques for high-power components, environmental protection, and comprehensive testing under actual operating conditions. Our assembly processes ensure reliable performance in demanding outdoor environments while maintaining cost-effectiveness for large installations.

High-Power Assembly Processes:

LED driver ICs and power management components utilize various packaging including high-thermal-pad QFN and exposed-pad packages requiring specialized SMT assembly techniques. Thermal interface materials and controlled reflow profiles ensure reliable thermal and electrical connections.

LED Display PCB Categories:

• Indoor LED Display PCBs: Fine-pitch modules (P1.25-P2.5) with high pixel density requiring precise assembly and advanced thermal management for close-viewing applications

• Outdoor LED Display PCBs: Weather-resistant designs (P4-P16) with IP65/IP67 protection, enhanced UV resistance, and temperature cycling qualification for permanent installations

• Stadium LED Display Systems: Large-format controllers for massive installations with fiber optic interfaces, redundant power supplies, and synchronized operation capabilities

• Transportation LED PCBs: Airport displays, highway signs, and public transit information meeting transportation authority specifications and reliability requirements

Comprehensive Testing Protocols:

High-current testing validates power handling capability under maximum load conditions. Optical testing using calibrated photometers ensures LED brightness uniformity and color accuracy. Environmental stress testing including thermal cycling, humidity exposure, and vibration qualification confirms reliability for outdoor installations.

LED Display PCB Applications and System Integration

HILPCB delivers LED Display PCB manufacturing solutions for outdoor advertising, sports venues, transportation systems, and architectural applications, ensuring reliable operation and scalable deployment from small installations through massive stadium displays.

Commercial Advertising Applications: Digital billboard controllers for outdoor advertising displays requiring maximum brightness, weather resistance, and 24/7 operation reliability. Recent projects include 10m x 6m billboard systems and shopping center LED walls with remote monitoring capabilities.

Sports and Entertainment Venues: Stadium perimeter displays, scoreboard systems, and arena LED installations supporting synchronized operation across hundreds of modules. Enhanced EMC compliance and structural integration for major league venues and entertainment facilities.

Transportation and Infrastructure: Airport information displays, highway variable message signs, and public transit LED systems meeting transportation authority specifications. Enhanced reliability requirements and remote diagnostic capabilities for critical infrastructure applications.

Architectural and Retail Integration: Building facade LED systems, retail display walls, and corporate lobby installations requiring aesthetic integration and energy efficiency optimization. Custom form factors and specialized mounting systems for architectural applications.

Why Choose HILPCB for LED Display PCB Manufacturing

At HILPCB, we deliver comprehensive LED Display PCB manufacturing and assembly solutions, providing the specialized capabilities required for high-power LED applications from concept through mass deployment. Our expertise in thermal management, high-current design, and environmental protection ensures reliable performance in demanding installations.

Specialized Capabilities:

- High-Power Expertise: Heavy copper PCBs, aluminum substrates, and thermal management solutions for demanding LED applications

- Environmental Qualification: IP65/IP67 rated designs with comprehensive testing including temperature cycling, humidity resistance, and UV exposure validation

- Scalable Production: Flexible manufacturing supporting both prototype development and high-volume production for large installations

- Global Standards: ISO 9001:2015 certified with automotive and transportation approvals for specialized applications

Industry Leadership: Our Shenzhen location provides access to specialized LED component suppliers, high-power materials, and advanced manufacturing equipment, enabling rapid technology adoption and cost optimization while maintaining the quality standards required for professional LED display installations.

Frequently Asked Questions About LED Display PCB Manufacturing

Q: How do Chinese manufacturers handle the extreme power requirements of LED displays? A: Chinese LED Display PCB manufacturers have invested in specialized equipment and expertise for high-power electronics manufacturing. We use heavy copper processing, aluminum substrates, and high-current testing capabilities developed through extensive experience in power electronics manufacturing.

Q: What quality standards ensure LED Display PCBs survive outdoor environments? A: We implement comprehensive environmental testing including IP65/IP67 validation, thermal cycling from -40°C to +85°C, UV exposure testing, and vibration qualification. All outdoor LED Display PCBs undergo accelerated aging to ensure long-term reliability.

Q: Can you manufacture both small indoor modules and large outdoor displays? A: Yes, we handle the complete range from fine-pitch indoor modules (P1.25) to large outdoor displays (P16). Our manufacturing capabilities include precision assembly for high-density applications and large-format boards for outdoor installations.

Q: What's the typical lead time for LED Display PCB manufacturing? A: Standard LED Display PCB prototypes require 7-10 days with production quantities typically delivered within 15-25 days. We maintain inventory of common LED components and power devices to reduce lead times for volume orders.

Q: Do you provide complete system integration beyond just PCB manufacturing? A: Our turnkey services include component sourcing, PCB fabrication, assembly, testing, and system-level validation. We work with LED suppliers, power component manufacturers, and system integrators to provide complete solutions for LED display projects.