Rigorous reliability testing validates Metal Core PCB performance across intended operating lifetimes, preventing field failures that damage reputation and incur warranty costs. At Highleap PCB Factory, our comprehensive testing protocols exceed IPC standards, ensuring MCPCBs deliver consistent thermal management throughout product lifecycles. This guide details testing methodologies, failure analysis techniques, and quality assurance strategies for reliable thermal PCB solutions.

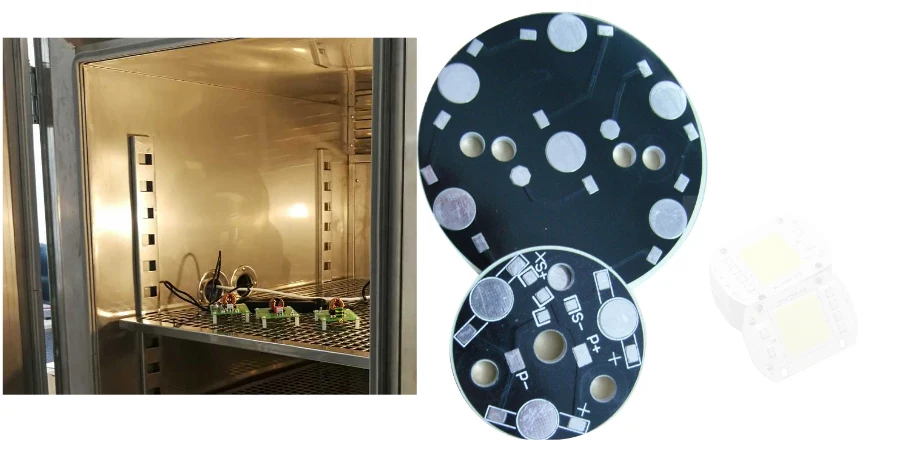

Thermal Cycling Test Protocols

Thermal cycling represents the most critical reliability test for MCPCBs, simulating temperature fluctuations experienced during operation and environmental exposure.

Standard Test Conditions: IPC-TM-650 Method 2.6.7.1 defines standard thermal cycling parameters. Temperature range typically -40°C to +125°C for general applications, extending to -55°C to +150°C for military/aerospace. Dwell time 10-30 minutes ensuring thermal equilibrium. Transition rate 10-15°C/minute preventing thermal shock effects. Cycle count varies: 500 cycles for consumer products, 1000 cycles for industrial, 2000+ cycles for automotive MCPCB standards applications.

Failure Mechanisms Detection: Delamination between aluminum PCB substrate and dielectric manifests as blistering or separation. Coefficient of thermal expansion (CTE) mismatch creates stress concentrations at interfaces. Solder joint fatigue develops from repeated thermal excursions causing intermittent failures. Via barrel cracking results from z-axis expansion differences. Trace lifting occurs when adhesion degrades under thermal stress.

Advanced Cycling Variations: Power cycling adds electrical load during temperature transitions simulating actual operation. Rapid temperature cycling (RTC) uses liquid-to-liquid transfer achieving 40°C/minute rates. Combined environment testing adds vibration during thermal cycling. Humidity exposure between cycles accelerates corrosion mechanisms. Mini-cycles around operating temperature detect marginal designs.

Reliability Test Matrix

| Test Method | Standard | Duration | Key Parameters |

|---|---|---|---|

| Thermal Cycling | IPC-TM-650 2.6.7 | 500-2000 cycles | -40/+125°C, 10min dwell |

| HAST | JESD22-A110 | 96-264 hours | 130°C/85%RH/33psi |

| Thermal Shock | MIL-STD-883 | 100-300 cycles | Liquid-liquid transfer |

| Salt Spray | ASTM B117 | 48-1000 hours | 5% NaCl, 35°C |

Accelerated Life Testing Methods

Accelerated testing predicts long-term reliability through elevated stress conditions, compressing years of operation into weeks of testing.

HAST (Highly Accelerated Stress Test): Temperature-humidity-bias testing accelerates moisture-related failures. Conditions: 110-130°C, 85%RH, 33-49 psi pressure, with or without electrical bias. Acceleration factor 50-100x versus field conditions. Failure modes include corrosion, dendrite growth, and delamination. 264 hours HAST approximates 10+ years field exposure. Bias voltage accelerates electrochemical migration failures.

THB (Temperature Humidity Bias): Standard conditions: 85°C/85%RH with applied voltage bias. 1000 hours exposure simulates 5-7 years typical field conditions. Lower acceleration factor than HAST but better correlation with field failures. Monitors insulation resistance degradation over time. Effective for detecting moisture sensitivity and ionic contamination issues.

Power Temperature Cycling: Combines thermal cycling with electrical power dissipation. Junction temperature excursions stress die attach and wire bonds. ON/OFF cycling creates thermal gradients within packages. Accelerates solder joint fatigue under actual operating conditions. Monitors thermal resistance increase indicating degradation.

Mechanical Stress Testing

Mechanical testing validates MCPCB structural integrity under handling, assembly, and operational stresses.

Bend Test Requirements: IPC-TM-650 Method 2.4.5 defines standard bend test procedures. 1% strain minimum for rigid boards, 2% for automotive applications. Support span and load point geometry affect stress distribution. Copper core PCB substrates require modified parameters due to higher stiffness. Pass criteria: no cracks, delamination, or electrical failures.

Vibration Testing Protocols: Sinusoidal vibration 10-2000 Hz sweeps identify resonant frequencies. Random vibration simulates real-world conditions more accurately. Power spectral density profiles match application environments. Automotive: 10g acceleration typical, aerospace up to 20g. Duration 8-24 hours per axis depending on application severity.

Shock and Drop Testing: Mechanical shock testing validates handling robustness. Half-sine pulse 50-1500g peak acceleration, 0.5-11ms duration. Drop testing from 1-2 meters simulates handling accidents. Board support conditions significantly affect results. Component attachment integrity primary failure concern.

Environmental Exposure Testing

Environmental testing validates MCPCB performance under various atmospheric conditions encountered during storage and operation.

Corrosion Resistance Validation: Salt spray testing (ASTM B117) evaluates corrosion protection. Mixed flowing gas testing simulates industrial atmospheres. Cyclic corrosion testing alternates salt spray with drying. Surface finish quality critical for corrosion resistance. Conformal coating effectiveness validation under environmental stress.

UV Exposure Testing: Ultraviolet radiation degrades polymer materials over time. Solder mask color stability important for appearance. White solder masks for LED applications require UV stability. ASTM G154 defines standard UV test cycles. 1000 hours exposure simulates 5+ years outdoor service.

Altitude and Pressure Testing: Low pressure testing simulates high altitude operation. Partial discharge inception voltage decreases with altitude. Outgassing concerns for space applications. Pressure cycling stresses hermetic seals. Combined altitude-temperature testing for aerospace applications.

Failure Analysis Techniques

Visual Inspection

- Optical microscopy 10-1000x

- Surface defect identification

- Solder joint inspection

- Delamination detection

Cross-Sectioning

- Internal structure analysis

- Via quality assessment

- Layer thickness measurement

- Crack propagation study

Advanced Methods

- SEM/EDX analysis

- Acoustic microscopy

- X-ray inspection

- Thermal imaging

Electrical Reliability Validation

Electrical testing ensures MCPCB maintains specified performance throughout operational lifetime under various stress conditions.

Insulation Resistance Testing: Measure dielectric integrity between circuit and metal substrate. Apply 500-1000VDC test voltage monitoring leakage current. Minimum 1×10⁸ Ω resistance required for quality boards. Temperature and humidity affect insulation resistance significantly. Surface contamination dramatically reduces measured values.

Dielectric Withstanding Voltage: Hi-pot testing verifies breakdown voltage exceeds specification. Apply 2x operating voltage +1000V for production testing. Monitor leakage current during voltage application. Partial discharge detection for high-voltage applications. Breakdown typically occurs at defect sites or contamination.

Continuity and Isolation: Flying probe or bed-of-nails testing verifies connectivity. Four-wire measurement ensures accurate low-resistance readings. Isolation testing between independent circuits prevents shorts. Temperature coefficient of resistance monitoring detects marginal connections. Contact resistance increases indicate degradation.

Thermal Performance Validation

Thermal testing confirms MCPCB achieves designed heat dissipation performance maintaining component junction temperatures within specification. These tests complement thermal simulation predictions with real-world validation.

Thermal Resistance Measurement: Steady-state thermal resistance characterizes heat flow efficiency. Apply known power measuring temperature differential. Junction-to-case and case-to-ambient measurements required. Compare results with design calculations and simulations. Lower thermal resistance indicates better performance.

Transient Thermal Testing: Dynamic thermal impedance reveals time-dependent behavior. Structure function analysis identifies thermal path bottlenecks. Die attach quality assessment through transient response. Thermal interface material performance validation. Identifies assembly defects affecting heat transfer.

Infrared Thermography: Non-contact temperature mapping during operation. Hot spot identification reveals design weaknesses. Temperature gradient visualization confirms heat spreading. Transient thermal events captured with high-speed cameras. Emissivity calibration ensures accurate measurements.

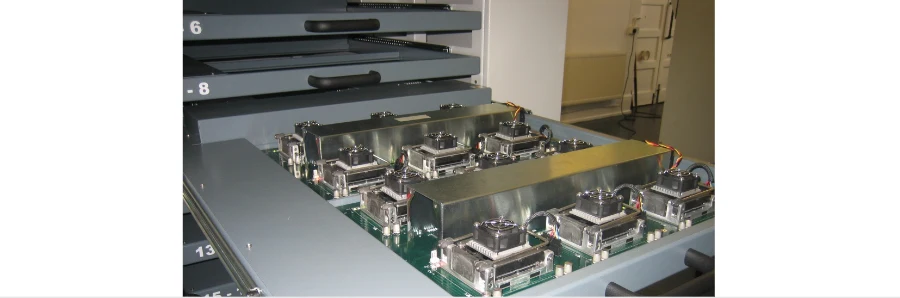

Quality Control Integration

Integrating reliability testing into production quality control ensures consistent performance across manufacturing batches.

Sampling Plans: Statistical sampling per MIL-STD-105 or equivalent. Lot acceptance based on AQL levels appropriate for application. Destructive testing on representative samples. 100% screening for critical parameters. Continuous monitoring through SPC charts.

Process Monitoring: In-process testing identifies issues before completion. Thermal conductivity verification on material samples. Dielectric thickness measurement ensures consistency. Adhesion testing validates lamination quality. Ionic contamination testing prevents field failures.

Data Management: Comprehensive test data recording and analysis. Trend analysis identifies process drift early. Correlation between test results and field performance. Database enables rapid failure investigation. Continuous improvement through data-driven decisions.

Test Equipment Requirements

Environmental Chambers

- Temperature range: -70°C to +180°C

- Humidity control: 10-98% RH

- Ramp rate: 5-15°C/minute

- Chamber size for panel testing

Electrical Test Systems

- Hi-pot tester: 0-5kVDC/AC

- Insulation resistance: up to 10¹² Ω

- 4-wire resistance: μΩ resolution

- Automated test fixtures available

Analysis Equipment

- Optical microscope: 10-1000x

- SEM/EDX for failure analysis

- X-ray for internal inspection

- Thermal camera: 0.05°C resolution

Failure Analysis Procedures

Systematic failure analysis identifies root causes enabling corrective actions preventing recurrence. Our comprehensive approach combines multiple analytical techniques revealing failure mechanisms.

Initial Assessment: Document failure symptoms and conditions. Photograph boards before destructive analysis. Review manufacturing and test records. Interview operators about observations. Establish failure timeline and pattern.

Non-Destructive Analysis: Visual inspection under magnification. X-ray inspection for internal defects. Electrical testing to characterize failure. Thermal imaging during powered operation. Acoustic microscopy for delamination.

Destructive Analysis: Cross-sectioning at failure location. SEM examination of fracture surfaces. EDX analysis for contamination. Microsectioning for detailed structure. Chemical analysis of residues.

Root Cause Determination: Compare findings with known failure modes. Correlate with process parameters. Review design against requirements. Identify contributing factors. Develop corrective action plan.

Continuous Improvement Through Testing

Reliability testing drives continuous improvement in MCPCB design rules and manufacturing processes.

Design Optimization: Test results inform design rule updates. Material selection based on performance data. Process parameters refined through testing. Weak points identified and strengthened. Margin validation ensures robustness.

Process Enhancement: Manufacturing process adjustments based on failures. Material supplier qualification through testing. Equipment calibration verified by test results. Training needs identified through failure patterns. Documentation updated with lessons learned.

Customer Feedback Integration: Field failure analysis improves future designs. Warranty data correlation with test results. Application-specific test development. Customer satisfaction through reliability. Competitive advantage through superior quality.

Ensuring MCPCB Reliability Through Comprehensive Testing

Reliability testing transforms MCPCB manufacturing from production to assurance, validating performance across intended operating conditions and lifetimes. Comprehensive testing protocols identify potential failure modes before products reach the field, protecting reputation and minimizing warranty costs. Our advanced testing capabilities combined with expertise in MCPCB assembly and cost optimization ensure thermal management solutions meet the most demanding reliability requirements.

Partner with Highleap PCB Factory for MCPCBs backed by rigorous testing and proven reliability. Our comprehensive test facilities, experienced engineers, and commitment to quality ensure your thermal management solutions perform consistently throughout product lifecycles. Contact us today to discuss your reliability requirements and discover how our testing capabilities validate MCPCB performance for your critical applications.