Accurate thermal simulation transforms Metal Core PCB design from trial-and-error to predictive engineering. At Highleap PCB Factory, we leverage advanced simulation tools validating thermal performance before manufacturing, reducing development cycles 40-60% while ensuring first-pass success. This comprehensive guide covers simulation methodologies, software tools, and validation techniques for optimizing MCPCB thermal designs.

Fundamentals of MCPCB Thermal Modeling

Effective thermal simulation requires accurate representation of MCPCB construction, material properties, and boundary conditions. Understanding modeling fundamentals ensures simulation results correlate with real-world performance.

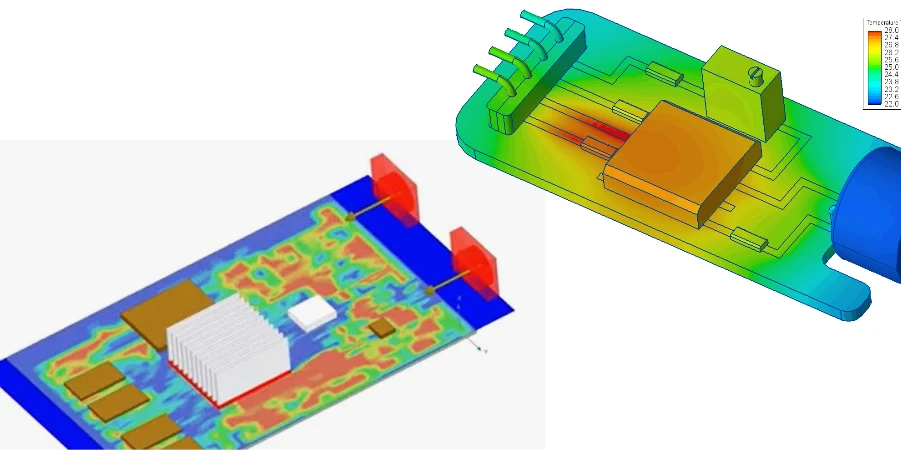

Multi-Layer Thermal Modeling: MCPCBs require three-dimensional modeling capturing metal substrate, dielectric layer, and circuit copper interactions. The aluminum PCB substrate acts as primary heat spreader with 140-200 W/m·K conductivity. Dielectric layers create thermal resistance requiring accurate thickness and conductivity modeling. Circuit copper contributes lateral heat spreading especially for heavy copper designs. Interface resistances between layers significantly impact thermal performance requiring careful characterization.

Material Property Definition: Accurate material properties ensure simulation validity. Aluminum substrates: 140-200 W/m·K thermal conductivity, 2700 kg/m³ density, 900 J/kg·K specific heat. Copper core PCB: 385-400 W/m·K conductivity, 8960 kg/m³ density, 385 J/kg·K specific heat. Dielectric materials: 1.0-8.0 W/m·K depending on formulation, temperature-dependent properties for accuracy. Component packages require detailed thermal models including die attach, wire bonds, and mold compound properties.

Boundary Condition Specification: Realistic boundary conditions determine simulation accuracy. Convection coefficients: 5-10 W/m²·K natural convection, 25-100 W/m²·K forced air cooling. Radiation effects become significant above 50°C requiring surface emissivity definition. Mounting interfaces create additional thermal resistance requiring contact resistance modeling. Ambient temperature variations affect cooling performance requiring worst-case analysis.

Simulation Software Comparison

| Software | Strengths | MCPCB Features | Learning Curve |

|---|---|---|---|

| ANSYS Icepak | Detailed 3D analysis | Full layer modeling | Steep |

| FloTHERM | PCB-specific tools | Built-in MCPCB templates | Moderate |

| SolidWorks Flow | CAD integration | Basic thermal analysis | Gentle |

| COMSOL | Multiphysics coupling | Custom physics | Very steep |

Advanced Simulation Techniques

Sophisticated simulation approaches capture complex thermal phenomena ensuring accurate MCPCB performance prediction. Advanced techniques address nonlinearities, transient effects, and coupled physics interactions.

Transient Thermal Analysis: Power cycling creates temperature fluctuations requiring time-dependent simulation. Thermal mass effects in metal substrates provide transient buffering. Die temperature response lags power changes affecting junction temperature peaks. Solder joint fatigue depends on temperature cycling amplitude and frequency. PWM switching effects require fine temporal resolution capturing microsecond heating dynamics. Correlate with reliability testing for validation.

Nonlinear Effects Modeling: Temperature-dependent material properties affect high-temperature accuracy. Thermal conductivity decreases 0.1-0.3%/°C for metals requiring iterative solutions. Radiation becomes dominant above 100°C requiring view factor calculations. Contact resistance varies with pressure and temperature affecting interface modeling. Natural convection coefficients change with temperature differential requiring correlation updates.

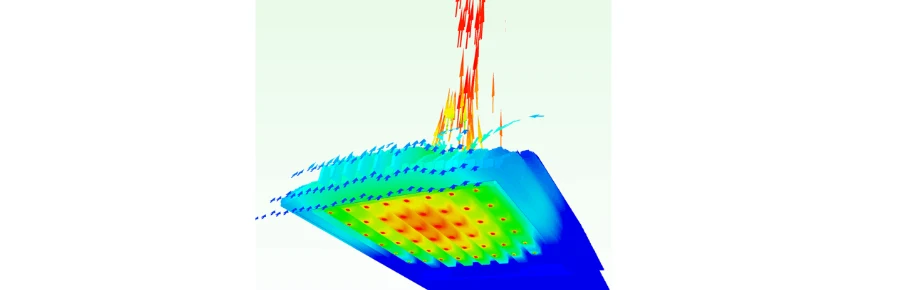

Coupled Physics Simulation: Electrical-thermal coupling captures Joule heating in traces and vias. Current density concentration at corners creates localized hot spots. Temperature affects electrical resistance creating positive feedback requiring iteration. Mechanical stress from CTE mismatch impacts reliability requiring thermo-mechanical analysis. Fluid flow modeling for forced convection requires CFD coupling.

Validation Methodology and Correlation

Simulation validation ensures model accuracy and builds confidence in predictive capabilities. Systematic correlation between simulation and measurement establishes model reliability.

Physical Testing Correlation: Thermocouple measurements validate junction and case temperatures. Infrared thermography provides full-field temperature mapping for model correlation. Thermal test vehicles with embedded sensors enable detailed validation. Power cycling tests confirm transient model accuracy. Environmental testing validates boundary condition assumptions. Follow MCPCB design rules for test vehicle design.

Model Calibration Process: Initial correlation identifies model discrepancies requiring adjustment. Interface resistance tuning matches measured thermal impedance. Convection coefficient adjustment aligns surface temperatures. Material property refinement improves agreement especially for dielectrics. Mesh sensitivity studies ensure numerical accuracy without excessive computation.

Uncertainty Quantification: Monte Carlo analysis captures material property variations. Sensitivity studies identify critical parameters affecting results. Worst-case analysis ensures robust design margins. Statistical correlation validates model confidence intervals. Design margins account for modeling uncertainties ensuring reliable operation.

LED Application Thermal Modeling

LED applications require specialized thermal modeling addressing unique LED characteristics and optical-thermal interactions. Accurate modeling ensures optimal performance and lifetime.

Junction Temperature Prediction: LED efficiency depends strongly on junction temperature requiring accurate modeling. Thermal resistance from junction to solder point varies with package design. Phosphor heating in white LEDs adds complexity requiring separate thermal zones. Multiple LED arrays create thermal crosstalk affecting individual junction temperatures. Dynamic thermal compact models enable system-level simulation. Consider MCPCB assembly effects on thermal performance.

Optical-Thermal Coupling: Light extraction efficiency decreases with temperature affecting heat generation. Phosphor conversion efficiency temperature dependence impacts thermal load. Optical feedback from reflective substrates affects absorption. Color shift with temperature requires coupled optical-thermal optimization. Lifetime prediction models link junction temperature to L70 degradation.

System-Level Optimization: Heat sink integration requires modeling complete thermal path. Natural versus forced convection trade-offs guide cooling design. Thermal via placement optimization balances cost against performance. PCB layout affects spreading resistance requiring iterative optimization. Driver placement impacts both electrical and thermal performance. Review MCPCB cost analysis for optimization trade-offs.

Simulation Best Practices

Model Preparation

- Simplify geometry while preserving heat paths

- Use symmetry/2D-axi where valid to cut runtime

- Include TIMs, solder, vias & copper planes

- Use temperature-dependent properties

Mesh Strategy

- Refine at TIM/solder/via & hot-spot regions

- Ensure ≥3–5 elements through thin layers

- Add boundary layers for convection/CFD

- Run mesh-independence & y⁺ checks (if CFD)

Solver Control

- Track residuals; energy balance < 1%

- Pick Δt from thermal time constant (Rθ·C)

- Use coupled CHT for solid/air when needed

- Stabilize parametric runs with tight tolerances

Validation & Reporting

- Correlate with IR/thermocouple measurements

- Sensitivity & uncertainty budget (mesh/BCs)

- Report KPIs: Tj, ΔT, Rθ, Tmax vs. limits

- Convert findings into clear design actions

Power Electronics Thermal Modeling

Power electronics applications create extreme thermal challenges requiring sophisticated modeling approaches. Accurate simulation enables power density optimization while ensuring reliability.

Switching Device Modeling: MOSFET and IGBT losses include conduction and switching components. Temperature-dependent on-resistance affects conduction losses. Switching losses depend on voltage, current, and frequency. Thermal network models capture die, substrate, and package thermal paths. Transient thermal impedance characterizes pulse power capability. Consider automotive MCPCB standards for vehicle applications.

Current Density Effects: High current traces create significant Joule heating requiring detailed modeling. Via arrays concentrate current creating localized hot spots. Skin effect at high frequencies affects current distribution. Thermal vias near high-current paths require optimization. Bus bar interfaces create additional thermal resistance.

Cooling System Integration: Liquid cooling integration requires fluid-thermal coupling. Heat pipe solutions need two-phase heat transfer modeling. Forced air cooling demands CFD analysis for flow optimization. Natural convection designs require orientation sensitivity analysis. Phase change materials provide transient thermal buffering.

Parametric Studies and Optimization

Systematic parametric studies identify optimal MCPCB configurations balancing performance, cost, and manufacturability.

Design Space Exploration: Substrate thickness variations affect thermal spreading and weight. Dielectric conductivity trade-offs between isolation and heat transfer. Via density optimization balances thermal performance with cost. Copper weight impacts both electrical and thermal performance. Component placement sensitivity affects system thermal resistance.

Multi-Objective Optimization: Thermal performance versus cost trade-off analysis. Weight minimization for portable and aerospace applications. Size reduction while maintaining thermal performance. Reliability maximization through stress minimization. Manufacturing yield optimization through robust design.

Sensitivity Analysis: Identify parameters with greatest impact on thermal performance. Tolerance stack-up effects on worst-case temperatures. Material property variations impact on design margins. Boundary condition uncertainties affecting results. Manufacturing process variations influence on performance.

Simulation-to-Manufacturing Workflow

Initial Design

Concept thermal modeling

Material selection

Preliminary layout

Detailed Analysis

3D thermal simulation

Transient analysis

Optimization studies

Prototype Validation

Physical testing

Model correlation

Design refinement

Production

Manufacturing transfer

Quality verification

Continuous improvement

Thermal-Ready Power & Automotive PCBs — From Simulation to Scalable Manufacturing

Design high-power and automotive boards that hit junction-temperature targets and pass lifetime tests, then scale cleanly to mass production. We combine physics-based thermal modeling with manufacturable stack-ups (MCPCB / heavy copper PCB) and assembly controls to de-risk your launch.

Power-Density Reality, Engineered

- Switching devices: MOSFET/IGBT conduction & switching losses vs. junction temperature modeled with transient thermal impedance; die—substrate—package paths captured in compact thermal networks.

- Current density effects: Joule heating on wide traces and vias, current crowding & skin effect hotspots; optimized via fields near high-current paths; bus-bar interface characterization.

- Integrated cooling: TIM + heatsink contact, baseplate spreading resistance, liquid-cooling co-simulation, PCM buffering, and vapor-chamber two-phase spreading—selected for cost, weight, and manufacturability.

Automotive-Grade Requirements, Designed-In

- Environment & stress: −40 °C to +125 °C, thermal shock, power cycling, humidity, and vibration/thermal-interface coupling.

- Reliability models to margins: Coffin—Manson, Arrhenius, Weibull, and physics-of-failure mapped to actionable design limits.

- Multi-domain constraints: EMC-driven placement, heatsink/mounting limits, weight and cost ceilings—resolved in the thermal stack and layout.

Simulation-Driven Optimization that You Can Build

- Parametric sweeps (substrate/dielectric conductivity, copper weight, via pattern, placement) plus DoE/Taguchi/RSM to expose sensitivities.

- Multi-objective optimization balances thermal, electrical, mass, and cost; ML surrogates/genetic search accelerate iteration to a manufacturable optimum.

Manufacturing-Ready Deliverables

- Validated stack-ups (thickness, isolation, copper weight), drill/slot/countersink and panelization rules for yield.

- Assembly controls (stencil/aperture, oxide control, reflow profiles for aluminum/copper cores) and reliability plans (thermal cycling/thermal shock/Hi-Pot/warpage).

- One-stop build with DFM feedback, pilot runs, and scalable production.

Accelerating MCPCB Development Through Simulation

Thermal simulation transforms thermal management PCB development from costly iterations to predictive design. Accurate modeling reduces prototype cycles, validates performance before manufacturing, and optimizes designs for cost and reliability. Our simulation services complement proven manufacturing processes ensuring thermally optimized solutions.

Partner with Highleap PCB Factory for comprehensive thermal simulation support throughout your MCPCB development. Our experienced engineers combine advanced simulation tools with manufacturing expertise, ensuring designs achieve thermal targets while remaining cost-effective and manufacturable. Upload your design for complimentary thermal analysis and optimization recommendations tailored to your application requirements.