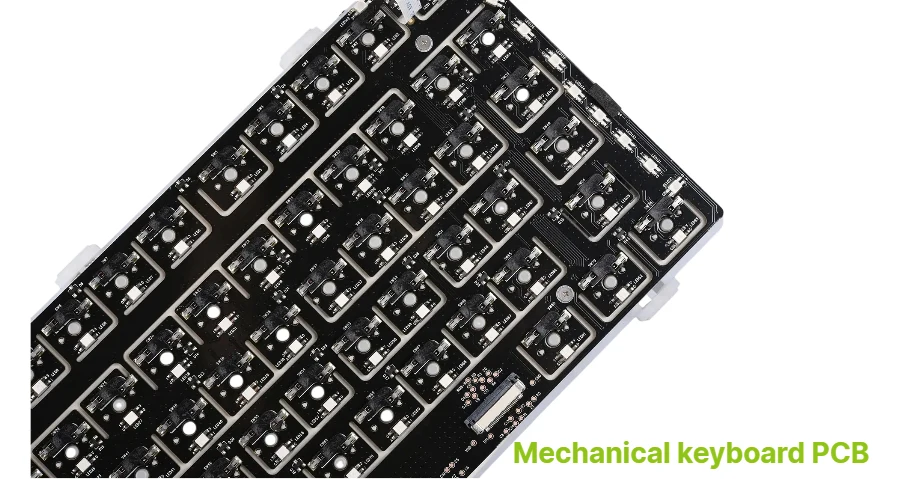

The mechanical keyboard revolution has transformed typing from a necessity into an art form. Behind every satisfying keystroke lies a precisely engineered Mechanical Keyboard PCB that manages complex switch matrices, RGB lighting systems, wireless connectivity, and programmable firmware. Whether it's a competitive gaming setup or a productivity powerhouse, these circuit boards define the modern typing experience.

At HILPCB, we specialize in manufacturing advanced electronic assemblies for gaming hardware, computer peripherals, consumer electronics, and industrial applications. Our Mechanical Keyboard PCB manufacturing combines cutting-edge technology with artisan-level attention to detail, delivering solutions that exceed the expectations of keyboard enthusiasts and commercial manufacturers alike.

Mechanical Keyboard PCB Categories and Layouts

Enthusiast and Custom Keyboards:

- 60% Keyboard PCB: Compact 61-key layouts for minimalist setups with maximum desk space

- 65% Keyboard PCB: 68-key designs adding dedicated arrow keys and function row access

- 75% Keyboard PCB: Compressed full-function layouts with F-row and compact spacing

- TKL Keyboard PCB: Tenkeyless designs for gaming-focused and professional applications

Gaming-Optimized Designs:

- Gaming Keyboard PCB: Ultra-fast scanning with 1000Hz polling and N-key rollover

- Hot Swap Gaming PCB: Tool-free switch replacement for competitive advantage customization

- RGB Gaming Keyboard PCB: Per-key addressable lighting with advanced effect synchronization

- Tournament Keyboard PCB: Competition-grade reliability with anti-ghosting and macro support

Wireless and Portable Solutions:

- Wireless Keyboard PCB: Bluetooth 5.0 and 2.4GHz connectivity with extended battery life

- USB-C Keyboard PCB: Modern connector standards with fast charging and data transmission

- Split Keyboard PCB: Ergonomic two-piece designs with customizable key positioning

- Travel Keyboard PCB: Ultra-portable designs with foldable and compact form factors

Professional and Ergonomic Applications:

- Ergonomic Keyboard PCB: Curved and angled layouts reducing repetitive strain injuries

- Programmable Keyboard PCB: Full QMK/VIA firmware support with unlimited customization

- Macro Pad PCB: Dedicated function pads with rotary encoders and OLED displays

- Industrial Keyboard PCB: Ruggedized designs for manufacturing and harsh environments

Advanced Manufacturing Technologies and Assembly

Our Mechanical Keyboard PCB production leverages specialized manufacturing processes tailored for keyboard applications:

Hot-Swap Socket Integration

Modern Hot Swap Keyboard PCB designs require precision placement of Kailh, Gateron, or Mill-Max sockets using SMT assembly techniques. Our automated placement systems ensure perfect alignment and consistent solder joint quality for thousands of switch insertion cycles.

Multi-Layer Design Optimization

Complex RGB Keyboard PCB layouts utilize multilayer PCB construction to separate switch matrices from LED control circuits, minimizing electromagnetic interference while supporting advanced lighting effects and wireless connectivity modules.

Flexible Circuit Integration

Premium keyboards incorporate flex PCB technology for daughterboards, rotary encoder connections, and battery interconnects. This enables innovative designs like gasket-mount keyboards and split layouts while maintaining electrical reliability.

Quality Assembly Services

Our turnkey assembly services include firmware programming, switch socket installation, RGB LED placement, and comprehensive testing. We handle everything from prototype development to production quantities exceeding 100,000 units annually.

RGB Lighting Systems and Visual Integration

Modern Mechanical Keyboard PCBs feature sophisticated lighting architectures that enhance both aesthetics and functionality.

Advanced LED Control Systems: Per-key RGB illumination requires complex driver circuits managing hundreds of individual LEDs. HDI PCB technology enables dense LED placement while maintaining thermal management and signal integrity for smooth lighting animations.

Lighting Effect Processing: Dedicated lighting controllers process real-time effects including reactive typing, audio visualization, and game integration. Advanced algorithms synchronize lighting across multiple devices and platforms for immersive gaming experiences.

Power Management Optimization: RGB systems significantly impact battery life in wireless keyboards. Intelligent power management circuits adjust brightness levels, enable selective zone lighting, and implement adaptive frame rates to maximize usage time.

Software Ecosystem Integration: Modern RGB Keyboard PCB designs support extensive software customization through popular platforms like OpenRGB, SignalRGB, and manufacturer-specific software suites, enabling unlimited personalization possibilities.

Mechanical Keyboard Ecosystem and Accessories

Mechanical Keyboard PCB development involves comprehensive peripheral ecosystems and specialized components:

Switch and Stabilizer Systems:

- Switch Tester PCB: Sample boards for testing different mechanical switch types and characteristics

- Switch Lubing Station PCB: Automated switch modification and lubrication systems

- Stabilizer PCB: Dedicated stabilizer mounting systems for improved large key performance

- Switch Filming Jig PCB: Precision tools for switch modification and performance enhancement

Customization and Modification Tools:

- Keycap Puller PCB: Integrated keycap removal tools with LED status indicators

- Switch Opener PCB: Automated switch disassembly tools for enthusiast modifications

- Desolder Gun PCB: Professional desoldering equipment for PCB rework and repair

- Keyboard Tester PCB: Comprehensive testing platforms for switch and PCB validation

Case and Mounting Accessories:

- Daughterboard PCB: Modular connection systems for premium keyboard cases

- Rotary Encoder PCB: Volume and function control knobs with push-button functionality

- OLED Display PCB: Status screens showing layer information, time, and system status

- Wireless Charging PCB: Inductive charging systems for cable-free keyboard operation

Audio and Haptic Enhancement:

- Piezo Buzzer PCB: Audio feedback systems for typing confirmation and alerts

- Haptic Feedback PCB: Tactile response systems enhancing typing feel and gaming immersion

- Sound Dampening PCB: Acoustic optimization systems reducing ping and resonance

- Typing Analytics PCB: Performance monitoring systems tracking speed and accuracy metrics

Firmware and Programming Integration

Modern Mechanical Keyboard PCBs support advanced firmware ecosystems that enable unprecedented customization and functionality.

QMK Firmware Support: Custom Keyboard PCB designs integrate seamlessly with QMK (Quantum Mechanical Keyboard) firmware, enabling users to program custom key mappings, macros, and lighting effects. Our designs include bootloader support for easy firmware updates and customization.

VIA Compatibility: VIA-compatible Programmable Keyboard PCB designs allow real-time customization without firmware compilation. Users can modify layouts, create macros, and adjust settings through intuitive graphical interfaces.

Advanced Programming Features:

- Layer System Support: Multiple keyboard layouts accessible through function keys

- Macro Programming: Complex keystroke sequences and timing control

- Tap Dance Functions: Multiple actions from single key presses based on timing

- Combo Keys: Custom functions triggered by simultaneous key presses

Gaming Integration APIs: Gaming Keyboard PCB designs support integration with popular games and platforms, enabling reactive lighting, game-specific profiles, and performance analytics for competitive gaming applications.

Wireless Technology and Connectivity Solutions

Contemporary Mechanical Keyboard PCB designs balance wireless convenience with gaming performance requirements.

Multi-Protocol Wireless Systems: Advanced Wireless Keyboard PCB implementations support multiple connectivity options including Bluetooth 5.0 for device compatibility, 2.4GHz proprietary protocols for gaming performance, and USB-C for charging and wired operation.

Ultra-Low Latency Performance: Gaming-focused wireless systems achieve sub-1ms input latency through optimized RF circuits and dedicated gaming dongles. Advanced polling rates up to 8000Hz ensure competitive gaming performance rivals wired connections.

Battery Life Optimization: Extended operation utilizes high-Tg PCB materials for thermal stability during charging cycles. Smart power management systems adapt performance based on usage patterns, extending battery life to weeks or months between charges.

Charging and Power Systems: Modern keyboards incorporate USB-C fast charging, wireless charging capabilities, and battery health monitoring. Advanced power distribution ensures consistent performance throughout the entire battery discharge cycle.

Why Choose HILPCB for Mechanical Keyboard PCB Manufacturing

The mechanical keyboard market demands exceptional quality, customization flexibility, and rapid iteration capabilities. HILPCB delivers comprehensive manufacturing solutions that serve both keyboard enthusiasts and commercial manufacturers with equal expertise and dedication.

Our Mechanical Keyboard Advantages:

- Keyboard Expertise: 15+ years specializing in keyboard PCB design, manufacturing, and assembly

- Flexible Production: From 10-piece prototypes for enthusiast projects to 100,000+ unit production runs

- Quality Excellence: IPC-A-610 Class 3 standards with specialized keyboard testing protocols

- Customization Support: Full design services for unique layouts, features, and aesthetic requirements

- Fast Turnaround: 3-day prototypes and 7-day production runs for rapid market entry

Complete Manufacturing Services:

- PCB fabrication using premium FR4 PCB materials optimized for keyboard applications

- Precision hot-swap socket placement and RGB LED installation

- Firmware programming and testing with QMK/VIA compatibility verification

- Custom packaging and fulfillment services for keyboard brands and retailers

- Design consultation and optimization for cost-effective volume production

Whether you're developing premium enthusiast keyboards, competitive gaming peripherals, or innovative ergonomic solutions, our engineering team and manufacturing capabilities deliver the precision, reliability, and customization your projects require for market success.