Choosing the right mechanical keyboard PCB manufacturer is about more than finding a factory that can produce boards — it’s about working with a partner who understands the unique demands of mechanical keyboards and can scale with your brand’s growth. At HILPCB, we combine advanced PCB fabrication and assembly with deep expertise in keyboard-specific requirements, making us a trusted choice for both enthusiast startups and global OEMs.

From custom-designed mechanical keyboard PCBs for premium gaming boards to standard 104/108-key layouts for enterprise keyboards, our services cover the full spectrum of design, prototyping, and mass production. With strong process control, quick-turn prototyping, and scalable manufacturing capacity, we help brands bring reliable, high-performance keyboards to market faster and with greater confidence.

Mechanical Keyboard PCB Manufacturer Capabilities and Infrastructure

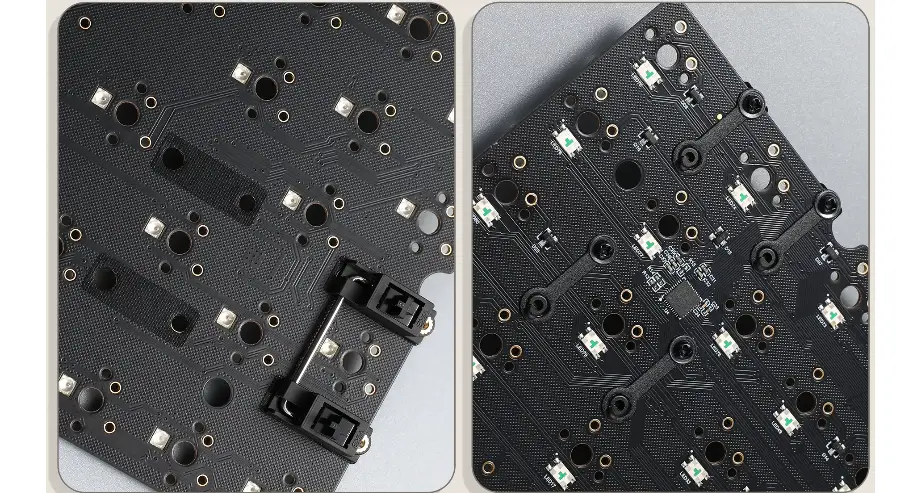

As an established Mechanical Keyboard PCB Manufacturer, we maintain comprehensive capabilities supporting every aspect of keyboard development and production. Our Keyboard PCB Factory infrastructure includes:

- Advanced PCB fabrication supporting 2-10 layer designs for Custom PCB Manufacturer requirements

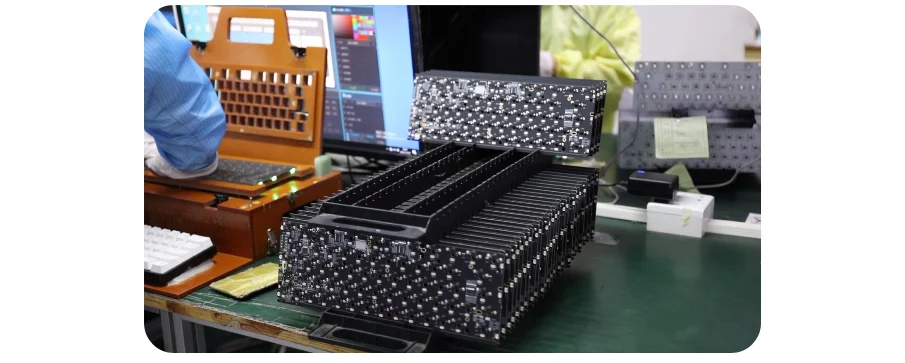

- High-volume SMT lines dedicated to Keyboard Production with 50,000+ components/hour

- Specialized testing equipment validating PCB Supplier quality standards

- ISO 9001:2015 certified OEM Keyboard Manufacturing processes

- In-house engineering supporting Mechanical Keyboard PCB Manufacturer design optimization

- Flexible production scaling from 100 to 1,000,000+ units annually

Our Keyboard PCB Factory employs over 500 skilled technicians with specific expertise in mechanical keyboard assembly. The facility spans 50,000 square feet of manufacturing space with dedicated lines for multilayer PCB production and SMT assembly.

Modern Custom PCB Manufacturer operations require rapid prototyping capabilities, with our quick-turn services delivering first articles in 24-48 hours for design validation.

Manufacturing Processes and Quality Systems

Our manufacturing processes are specifically optimized for mechanical keyboard requirements as a specialized Keyboard PCB Factory:

- PCB Supplier Processes: Automated optical inspection at every production stage

- Keyboard Production Standards: IPC-A-610 Class 2/3 assembly standards

- OEM Keyboard Manufacturing: Statistical process control maintaining Cpk > 1.33

- Mechanical Keyboard PCB Manufacturer: 100% electrical testing of finished boards

- Custom PCB Manufacturer: Batch traceability from raw materials through shipping

- Keyboard PCB Factory: Environmental testing including thermal cycling and humidity

Turnkey assembly capabilities as a comprehensive PCB Supplier include component sourcing, inventory management, and just-in-time delivery supporting lean manufacturing initiatives.

Technology and Innovation Leadership for Keyboard Manufacturing

Leading manufacturers must continuously innovate to meet evolving market demands and maintain competitive advantages in keyboard technology.

Manufacturing Technology Advantages

- Advanced HDI Capabilities Microvia and buried via technology enabling ultra-compact keyboard designs with maximum functionality.

- Flexible Manufacturing Systems Quick changeover between products supporting high-mix production environments efficiently.

- Automated Testing Systems Custom test fixtures validating every keyboard function including RGB, switches, and connectivity.

- Industry 4.0 Integration Real-time production monitoring, predictive maintenance, and quality analytics improving yields.

- Rapid Prototyping Services 24-hour PCB fabrication and assembly for urgent development projects.

Engineering Support Services

- Design for Manufacturing (DFM) Pre-production analysis optimizing designs for cost-effective manufacturing.

- Component Engineering Alternative sourcing and obsolescence management ensuring long-term availability.

- Firmware Development QMK/VIA integration and custom firmware supporting unique features.

- Compliance Management FCC, CE, RoHS certification support for global market access.

Mechanical Keyboard PCB Manufacturer Market Specializations

Our Mechanical Keyboard PCB Manufacturer services support diverse market segments:

- Gaming Keyboard Manufacturing for Esports and PC Gaming Brands

- Office Keyboard Production for Corporate and Enterprise Markets

- Enthusiast Keyboard PCB Factory Services for Group Buys and Custom Projects

- OEM Keyboard Manufacturing for Private Label and Retail Brands

- Industrial Keyboard Production for Specialized Applications

- Educational Market PCB Supplier for School and Institution Orders

- Regional Brand Support as Asia-Based Keyboard PCB Factory

Custom PCB Manufacturer capabilities extend beyond standard keyboards to specialized input devices including keypads, macro pads, and custom control surfaces.

Partnership and Support Services

Beyond manufacturing, we provide comprehensive partnership services as your Mechanical Keyboard PCB Manufacturer:

Supply Chain Management:

- Component sourcing leveraging $50M+ annual purchasing power

- Inventory management with bonded warehouse options

- Alternative component qualification during shortages

- Long-term supply agreements ensuring availability

Product Development Support:

- Industrial design consultation for new products

- Prototype iteration with rapid feedback cycles

- Beta testing and reliability validation

- Production ramp-up planning and execution

Business Support Services:

- Flexible payment terms for qualified customers

- Drop-shipping and fulfillment services

- Private labeling and custom branding

- Technical documentation and certification assistance

Why Choose HILPCB as Your Mechanical Keyboard PCB Manufacturer

Partnering with HILPCB means gaining access to a manufacturer that excels not only in keyboard PCBs but across the entire electronics landscape. We produce everything from gaming and office mechanical keyboard PCBs to PCBs for mice, headsets, microphones, and audio controllers — ensuring your peripherals can be developed and manufactured under one roof. This cross-category expertise helps our clients build cohesive ecosystems of products with consistent quality and performance.

Our broad set of certifications and rigorous quality systems reflect our commitment to reliability, safety, and compliance across global markets. Whether you need a prototype for a custom keyboard project or a large-volume production run for retail distribution, HILPCB delivers with a focus on precision, flexibility, and cost efficiency.

For brands looking to stand out in a competitive market, HILPCB is more than just a factory — we are a long-term partner for innovation, scale, and quality in mechanical keyboard PCBs and beyond.

Frequently Asked Questions – Mechanical Keyboard PCB Manufacturer

Q1: How to choose the right Mechanical Keyboard PCB Manufacturer?

A: Evaluate technical capabilities (layer count, HDI, assembly), quality certifications (ISO 9001, IPC standards), production capacity, keyboard-specific experience, communication responsiveness, and pricing transparency.

Q2: What certifications should a Keyboard PCB Factory have?

A: Essential certifications include ISO 9001 for quality management, IPC-A-610 for assembly standards, UL for safety, and RoHS for environmental compliance. ISO 14001 and IATF 16949 indicate advanced capabilities.

Q3: What's the typical MOQ for Custom PCB Manufacturer services?

A: MOQs vary: prototypes start at 5 units, small batch production typically requires 100+ units, while cost-effective mass production begins around 500-1000 units depending on complexity.

Q4: How do Keyboard Production lead times typically work?

A: Standard timelines: 24-48 hours for prototype PCBs, 2-3 weeks for assembled prototypes, 3-4 weeks for pilot runs, and 4-6 weeks for volume production including component sourcing.

Q5: Can a PCB Supplier help with component sourcing during shortages?

A: Yes, established manufacturers maintain relationships with multiple distributors, can source alternatives, hold strategic inventory, and often have allocation during shortages due to purchasing volume.

Q6: What support does OEM Keyboard Manufacturing typically include?

A: OEM services typically include design assistance, prototype development, testing and validation, production scaling, quality assurance, packaging/branding, and often logistics and fulfillment support.