At Highleap PCB Factory, we manufacture thermal management solutions for all high-power electronics applications—extending far beyond basic Metal Core PCBs. From power electronics and automotive systems to industrial equipment and renewable energy, our expertise in thermal PCB design ensures reliable performance across all industries. While this guide focuses on Metal Core PCB manufacturing, our comprehensive capabilities span every thermal challenge. Whether you need high-thermal PCB for extreme applications or heavy copper PCB for high-current designs, Highleap PCB Factory delivers complete thermal management solutions for advanced electronics across all sectors.

Advanced Thermal Management Through Metal Core Technology

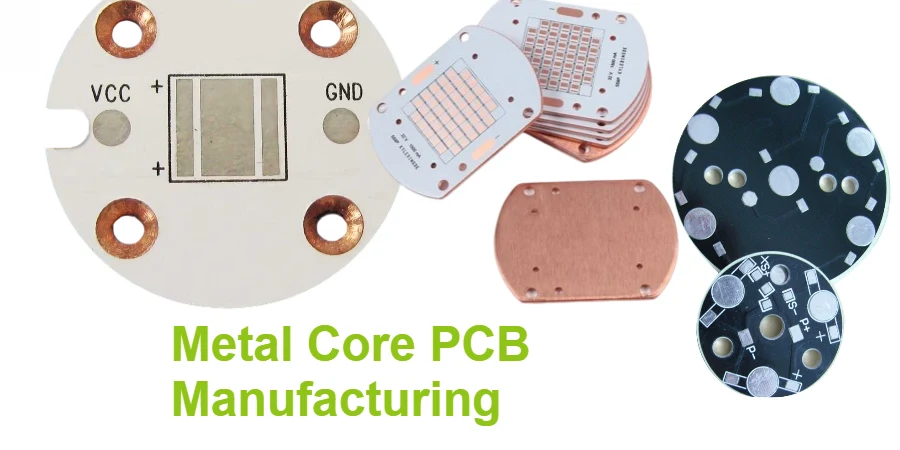

Metal Core PCBs represent a fundamental shift from traditional thermal management approaches, integrating heat spreading directly into the circuit board substrate. At Highleap PCB Factory, we manufacture MCPCBs that combine aluminum or copper substrates with precision-engineered dielectric layers, creating thermal highways that conduct heat 5-20 times more effectively than standard FR-4 boards.

Superior Heat Conduction Performance: Our MCPCB designs utilize specialized metal substrates that function as integrated heat spreaders, eliminating thermal bottlenecks that plague conventional PCB designs. The three-layer construction—metal substrate, thermally conductive dielectric, and copper circuit layer—creates direct thermal paths from heat-generating components to external cooling systems. Integrated aluminum PCB solutions provide cost-effective thermal management, while copper core PCB designs deliver ultimate performance for extreme power density applications.

Engineered for Reliability: Advanced thermal interface engineering ensures consistent performance across temperature extremes. Our dielectric layer technology, ranging from 1.0 to 8.0 W/m·K thermal conductivity, balances thermal performance with electrical isolation requirements. Coordinating with MCPCB design rules, thermal management PCB, and MCPCB assembly processes, our manufacturing expertise ensures thermal solutions translate directly into extended component lifetimes and improved system reliability.

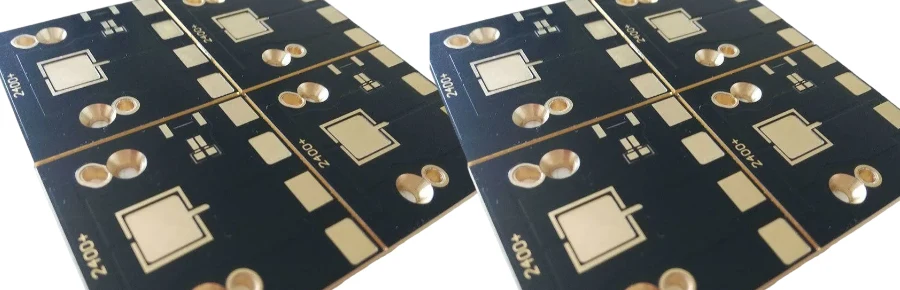

Manufacturing Excellence: Real-time thermal monitoring and precision lamination processes ensure consistent dielectric thickness and void-free interfaces. Statistical process control maintains thermal conductivity within specification while automated testing validates thermal resistance performance. This comprehensive approach reduces development risks and accelerates time-to-market for companies requiring proven thermal management solutions.

Thermal Performance Specifications

Standard Grade

Thermal Conductivity: 1.0-2.0 W/m·K

Applications: General LED lighting

Cost Factor: Base pricing

Enhanced Grade

Thermal Conductivity: 3.0-5.0 W/m·K

Applications: Automotive, high-power

Cost Factor: +40-60% premium

Premium Grade

Thermal Conductivity: 8.0 W/m·K

Applications: Extreme thermal challenges

Cost Factor: +100% premium

Substrate Material Engineering and Selection

The foundation of effective thermal management lies in optimal substrate material selection, balancing thermal conductivity, mechanical properties, cost, and manufacturing requirements for specific application needs.

Aluminum Substrate Technology: Aluminum cores provide the optimal balance of thermal performance and cost-effectiveness for most applications. Our aluminum substrates utilize 5052 and 6061 alloys offering 140-200 W/m·K thermal conductivity with excellent manufacturability. The lightweight construction (2.7 g/cm³) makes aluminum ideal for portable and automotive MCPCB standards applications where weight matters. Surface treatments including anodizing enhance corrosion resistance and thermal radiation, extending operational lifetime in harsh environments.

Copper Core Performance: For applications demanding maximum thermal performance, copper substrates deliver 385-400 W/m·K conductivity—nearly double aluminum performance. The superior thermal mass provides excellent transient response, absorbing heat spikes that would damage other substrates. While copper costs 3-4x more than aluminum, the performance benefits justify the investment for size-critical or extreme power density applications. Advanced thermal simulation validates design performance before manufacturing.

Dielectric Layer Engineering: The thermally conductive dielectric layer represents the critical thermal interface between circuit and substrate. Our dielectric technology spans from cost-effective 1.0 W/m·K materials for general applications to premium 8.0 W/m·K formulations for extreme thermal challenges. Layer thickness optimization balances thermal resistance with electrical isolation requirements, ensuring both thermal performance and safety compliance.

Application-Driven Design Solutions

Metal Core PCBs serve diverse industries with specific thermal management requirements, each demanding specialized design approaches and material selections.

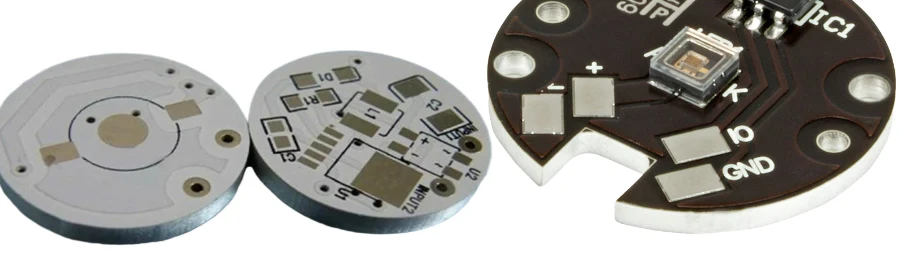

LED PCB Board Manufacturing Excellence

LED applications represent the largest MCPCB market segment, requiring specialized thermal and optical optimization. Our LED-specific designs incorporate white solder masks with >85% reflectivity, optimized thermal via patterns, and junction temperature calculations ensuring L70 lifetime predictions. Applications span from 50-300W street lighting modules to automotive matrix LED headlights requiring precise thermal control.

Automotive Electronics Integration

Automotive MCPCBs meet stringent reliability requirements including AEC-Q100 qualification, -40°C to +125°C operation, and 15-year lifetime expectations. Our automotive-grade designs incorporate vibration resistance, shock tolerance, and environmental sealing for harsh operating conditions. Electric vehicle applications including inverters and charging systems benefit from our high-power thermal management expertise.

Power Electronics Optimization

High-power applications including solar inverters, motor drives, and welding equipment leverage MCPCB thermal management for improved power density and efficiency. Our power electronics designs handle extreme current densities while maintaining safe operating temperatures, enabling miniaturization and performance improvements across diverse power applications.

Manufacturing Capabilities Overview

Size Range

10×10mm to 600×500mm single piece

Thickness Options

0.5-8.0mm metal substrate thickness

Copper Weight

1-20oz (35-420μm) options available

Lead Time

5-7 days prototypes, 10-15 days production

All specifications backed by ISO 9001:2015 and IATF 16949 certified processes

Quality Assurance and Manufacturing Excellence

Comprehensive quality systems ensure consistent thermal performance and electrical reliability across all MCPCB products. Our manufacturing processes incorporate statistical process control, real-time monitoring, and comprehensive testing protocols validating both thermal and electrical performance parameters.

Process Control Systems: ISO 9001:2015 and IATF 16949 certified manufacturing processes ensure consistent quality delivery. Real-time monitoring systems track critical parameters including lamination temperature, pressure, and dielectric thickness. Statistical process control maintains Cpk >1.33 for critical characteristics while continuous improvement programs drive ongoing optimization. Our reliability testing protocols validate long-term performance.

Thermal Performance Validation: Every production batch includes thermal conductivity verification and thermal resistance measurement. Infrared thermography mapping validates temperature distribution under operational loads while accelerated life testing confirms long-term reliability. Complete documentation including thermal test reports accompanies every shipment.

Global Manufacturing Support: Worldwide manufacturing facilities provide local support with global consistency. Advanced logistics networks ensure rapid delivery via DHL, FedEx, and UPS with real-time tracking. Technical support teams provide multilingual assistance including English, Chinese, Japanese, and German language capabilities.

Complete MCPCB vs FR-4 Solution Engineering

Understanding when to specify Metal Core PCBs versus traditional FR-4 requires comprehensive analysis of thermal requirements, electrical needs, mechanical constraints, and economic factors. Our engineering team provides guidance ensuring optimal technology selection for specific application requirements. Review our MCPCB cost analysis for detailed comparisons.

Design Decision Criteria: Choose MCPCB when power density exceeds 2W/cm², operating temperature approaches component limits, reliability requirements are strict, or size constraints demand efficient cooling. Consider FR-4 when power density remains below 1W/cm², multi-layer complexity is required, cost sensitivity is extreme, or thermal performance is adequate with conventional cooling methods.

Engineering Support Services: Our thermal engineers provide comprehensive design support including thermal analysis and simulation, material selection optimization, cost-performance trade-off analysis, and design rule compliance verification. Manufacturing support ensures smooth production through process development, yield improvement initiatives, and quality system implementation.

Global MCPCB Manufacturer Partnership

Highleap PCB Factory combines global manufacturing scale with local engineering support, ensuring consistent quality while providing responsive customer service. Our worldwide operations deliver reliable thermal management solutions with comprehensive technical support throughout the product lifecycle.

Advanced Manufacturing Infrastructure: State-of-the-art production facilities feature specialized equipment for metal substrate processing, precision lamination systems, and automated testing capabilities. Clean room assembly environments ensure contamination-free processing while statistical process control maintains consistent quality across all production runs.

Customer Partnership Approach: Technical consultation services, rapid prototyping capabilities, and volume production scaling ensure seamless support from concept through production. Lifecycle management support includes obsolescence management, design modifications, and performance upgrade consultation maintaining long-term customer success.

Your Complete Thermal Management Electronics Partner

While Metal Core PCBs demonstrate our thermal engineering expertise, Highleap PCB Factory manufactures circuit boards for every thermal management challenge. Power electronics, industrial equipment, automotive systems, renewable energy—our experience with sophisticated thermal design benefits all customers requiring reliable heat dissipation solutions. This comprehensive background ensures your thermal management products achieve exceptional performance and reliability.

Whether you need prototypes for innovative thermal concepts or thousands of units for commercial deployments, our integrated manufacturing capabilities deliver superior results. From initial thermal analysis through performance validation to volume production, we provide complete support ensuring your products succeed in demanding thermal environments. Choose Highleap PCB Factory for thermal management electronics that keep critical systems cool, efficient, and reliable.