From professional studio recordings to smartphone voice assistants and advanced conference systems, every audio capture experience depends on precisely engineered Microphone PCBs that transform acoustic waves into pristine digital signals. These sophisticated circuit boards integrate sensitive analog components, advanced signal processing, noise reduction algorithms, and wireless transmission systems.

At HILPCB, we manufacture cutting-edge electronic assemblies serving audio equipment, telecommunications, consumer electronics, and professional broadcasting industries. Our Microphone PCB solutions showcase our expertise in high-fidelity analog design while representing one specialized domain within our comprehensive electronics manufacturing capabilities.

Microphone PCB Technology and Audio Applications

Professional Recording Equipment:

- Studio Microphone PCB: High-end condenser microphones with ultra-low noise preamps and phantom power

- Broadcast Microphone PCB: Dynamic microphones for radio and television with integrated pop filters

- Instrument Microphone PCB: Specialized designs for musical instruments with frequency-specific optimization

- Ribbon Microphone PCB: Vintage-style ribbon microphones with transformer-coupled outputs

Consumer and Mobile Devices:

- MEMS Microphone PCB: Miniaturized silicon microphones for smartphones and earbuds

- Smartphone Microphone PCB: Multi-microphone arrays with noise cancellation and beamforming

- Headset Microphone PCB: Gaming and communication headsets with boom microphone integration

- Smart Speaker Microphone PCB: Far-field voice recognition with wake word detection

Wireless and Portable Systems:

- Wireless Microphone PCB: UHF and digital wireless systems with encrypted transmission

- Lavalier Microphone PCB: Miniature clip-on microphones for presentations and broadcasting

- Handheld Microphone PCB: Battery-powered microphones with integrated transmitters

- Body-Pack Microphone PCB: Compact wireless transmitters for performers and speakers

Professional and Industrial Applications:

- Conference Microphone PCB: Ceiling and table microphones with automatic mixing capabilities

- Security Microphone PCB: Surveillance microphones with long-range audio pickup

- Medical Microphone PCB: Stethoscope microphones and patient monitoring audio systems

- Automotive Microphone PCB: Hands-free calling and voice command systems for vehicles

Advanced Audio Signal Processing

Our Microphone PCB manufacturing combines precision analog design with sophisticated digital signal processing:

High-Fidelity Analog Front-End

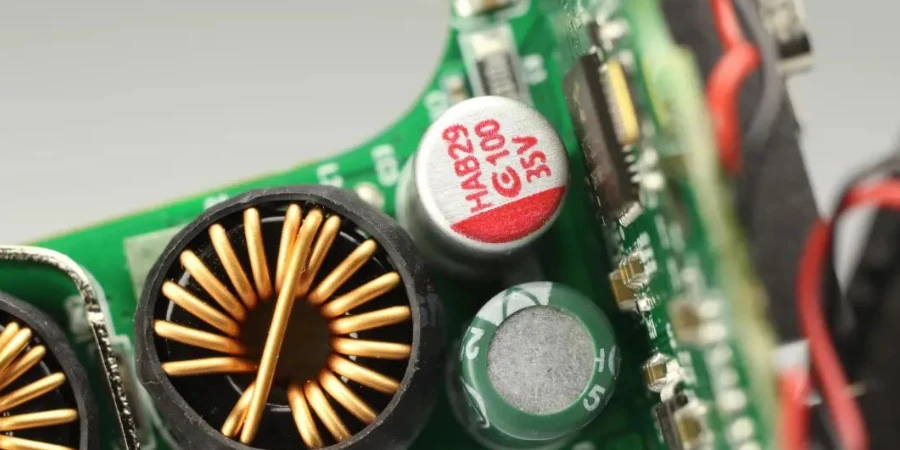

Professional Studio Microphone PCB designs require ultra-low noise analog circuits using multilayer PCB construction to isolate sensitive audio signals from digital switching noise. Precision ground planes and power distribution ensure optimal signal-to-noise ratios.

MEMS Integration and Assembly

Modern MEMS Microphone PCB systems utilize HDI PCB technology for ultra-compact microphone array implementations. SMT assembly processes handle miniature MEMS devices with specialized handling procedures for acoustic sensitivity preservation.

Digital Audio Processing

Advanced Microphone PCB designs integrate dedicated DSP processors for real-time noise reduction, echo cancellation, and beam forming. High-speed PCB design techniques ensure clean digital audio transmission and processing.

Flexible System Integration

Modern microphone systems utilize flex PCB technology for boom microphone connections, cable strain relief, and compact headset integration while maintaining excellent audio performance and mechanical durability.

Wireless Audio Technology and Connectivity

Contemporary Microphone PCB designs balance audio quality with wireless performance across professional and consumer applications.

Professional Wireless Systems: Wireless Microphone PCB designs for professional applications utilize dedicated UHF frequency bands with sophisticated frequency coordination and interference avoidance. Advanced RF circuits ensure reliable transmission with minimal dropouts during live performances.

Digital Wireless Innovation: Next-generation digital wireless systems integrate audio compression, error correction, and encryption within Microphone PCB designs. Low-latency codecs and adaptive bit-rate algorithms maintain audio quality while optimizing battery life and transmission reliability.

Battery Management Optimization: Extended operation requires intelligent power management using high-Tg PCB materials for thermal stability during charging cycles. Smart battery monitoring and adaptive transmission power extend usage time for critical applications.

Multi-Protocol Connectivity: Modern Microphone PCB systems support multiple wireless standards including Bluetooth, WiFi, and proprietary protocols for seamless integration with various audio equipment and smart devices.

Audio Ecosystem and Professional Accessories

Microphone PCB development increasingly involves comprehensive audio ecosystems and specialized peripheral products:

Recording Studio Equipment:

- Audio Interface PCB: Multi-channel microphone preamps with digital conversion and USB connectivity

- Mixer Console PCB: Live sound mixing boards with integrated microphone processing

- Monitor Speaker PCB: Studio reference monitors with bi-amplified crossover networks

- Audio Processor PCB: Hardware compressors, equalizers, and effects units for professional audio

Broadcast and Communication Systems:

- Intercom System PCB: Two-way communication systems for production teams

- Audio Router PCB: Broadcast audio routing and distribution matrices

- Telephone Interface PCB: Broadcast phone systems with caller audio processing

- Streaming Encoder PCB: Live streaming audio encoding and transmission systems

Consumer Audio Accessories:

- Audio Recorder PCB: Portable digital recorders with built-in microphone preamps

- Podcast Kit PCB: Complete podcasting solutions with integrated processing

- Gaming Audio PCB: Gaming headset amplifiers and virtual surround processing

- Smart Home Hub PCB: Voice assistant platforms with advanced microphone arrays

Industrial Audio Solutions:

- PA System PCB: Public address amplifiers and distribution systems

- Emergency Communication PCB: Mass notification systems with voice evacuation

- Hearing Loop PCB: Assistive listening systems for hearing-impaired users

- Noise Monitoring PCB: Environmental noise measurement and logging systems

HILPCB: Audio Electronics Manufacturing Excellence

Microphone PCB manufacturing demonstrates our expertise in high-fidelity analog design and precision audio electronics, representing one specialized segment of our comprehensive manufacturing capabilities. We serve diverse industries including telecommunications, medical devices, automotive, industrial automation, and consumer electronics.

Our Audio Manufacturing Advantages:

- Analog Design Expertise: Ultra-low noise circuit design with precision component placement and EMI control

- Scalable Audio Production: From 20-piece prototypes to millions of units for major audio equipment manufacturers

- Quality Audio Standards: IPC-A-610 Class 3 with specialized audio performance testing and validation protocols

- Advanced Materials: Rogers PCB and low-loss materials for RF wireless microphone applications

- Complete Assembly Services: Turnkey assembly including acoustic testing and calibration

Whether you're developing Microphone PCBs, audio processing systems, medical devices, automotive electronics, or any audio-related electronic assembly, our experienced team delivers the precision, innovation, and audio quality your products demand for market leadership.

Frequently Asked Questions

Q: What types of Microphone PCB do you manufacture and what audio quality can you achieve?

A: We manufacture all types of Microphone PCB including studio condenser microphones, MEMS microphone arrays, wireless microphone systems, and professional broadcast microphones. Our designs achieve professional audio specifications including THD+N below 0.01%, SNR exceeding 80dB, and frequency response from 20Hz to 20kHz.

Q: How do you ensure audio quality and minimize noise in Microphone PCB designs?

A: We implement specialized analog design techniques including dedicated ground planes, power supply filtering, component placement optimization, and EMI shielding. Our testing includes audio performance validation, THD measurement, frequency response analysis, and electromagnetic compatibility verification for professional audio standards.

Q: Can you support both consumer and professional audio applications?

A: Yes, we serve both markets with appropriate design standards and manufacturing processes. Consumer applications focus on cost optimization and miniaturization, while professional audio requires enhanced performance specifications, reliability testing, and compliance with broadcasting industry standards.

Q: What wireless technologies and audio codecs can you integrate into Microphone PCB systems?

A: We support all major wireless standards including UHF analog, digital wireless protocols, Bluetooth with aptX codecs, WiFi audio streaming, and proprietary low-latency systems. Advanced codec integration includes AAC, SBC, LDAC, and uncompressed digital audio transmission for professional applications.