The Crisis: Your production line just stopped. Testing revealed a critical bug. A key component went obsolete overnight. You need a fix NOW, not a 6-week redesign cycle.

The Solution: HILPCB's emergency PCB modification service implements targeted fixes within 24-48 hours. We modify existing designs surgically—changing only what's necessary to get production running again.

Real example: A medical device manufacturer discovered EMI failures during FCC testing. Complete redesign would take 8 weeks and $50,000. Our modification service fixed the issue in 3 days for $2,800 by adding strategic ground planes and repositioning three components.

Types of PCB Modifications We Handle in Under 48 Hours

Component Obsolescence Modifications

When distributors announce end-of-life with zero warning, we implement alternate parts fast. Our database contains 50,000+ verified component substitutions with proven footprint modifications. Recent project: Replaced obsolete Maxim power controller with TI equivalent, modified support circuitry, validated performance—36 hours total.

Typical modifications include:

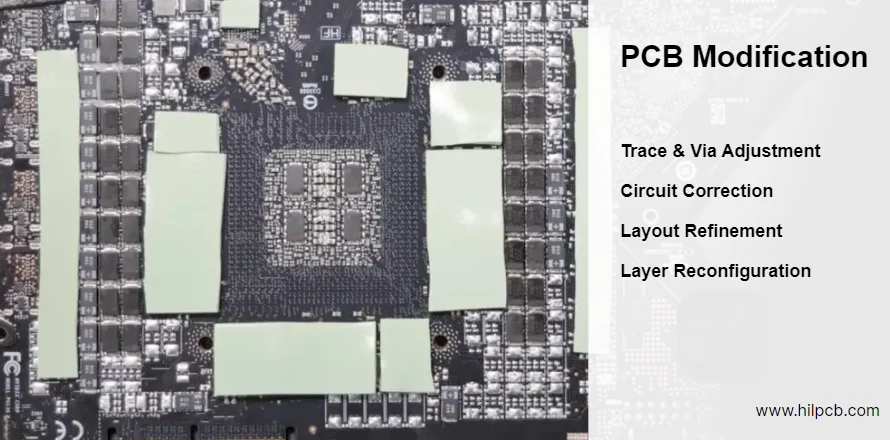

- BGA to QFN package conversions with routing adjustments

- Through-hole to SMT transitions for modernization

- Multi-source component options to prevent future shortages

- Pin-compatible substitutions with minimal trace changes

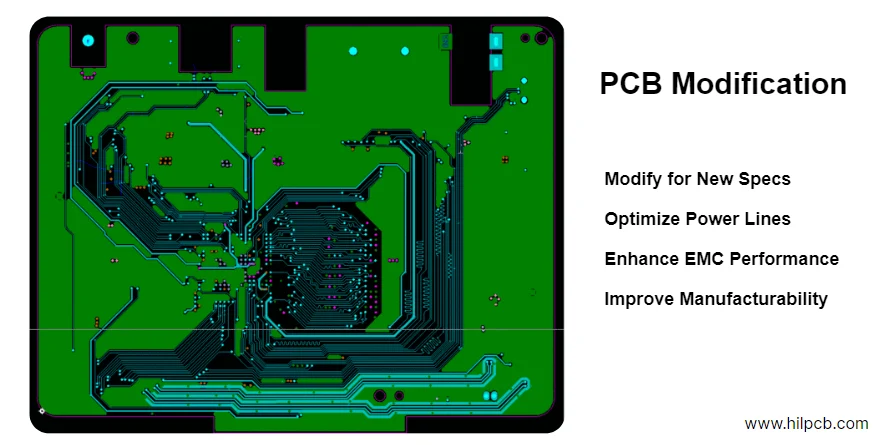

EMI/EMC Compliance Modifications

Failed emissions testing doesn't mean starting over. Strategic modifications often solve EMI issues without major redesign. We analyze test reports, identify emission sources, and implement targeted fixes.

Quick EMI fixes that work:

- Adding 0Ω resistors for filter insertion points (modify in 4 hours)

- Ground plane stitching via additions (modify in 8 hours)

- Crystal circuit guard ring implementation (modify in 12 hours)

- Differential pair rerouting for common-mode reduction (modify in 24 hours)

Production Yield Modifications

When assembly yields drop below 85%, minor modifications often restore profitability. We analyze AOI reports, ICT failures, and rework data to identify root causes.

Yield-improving modifications:

- Thermal relief adjustments for better soldering (4-hour modification)

- Pad size optimization for component tombstoning issues (6-hour modification)

- Via-in-pad filling for BGA assembly problems (24-hour modification)

- Stencil aperture adjustments for paste release (2-hour modification)

The 48-Hour PCB Modification Process

Hour 0-4: Emergency Assessment

- Engineer reviews your files and issue description

- Feasibility confirmation within 2 hours

- Cost and timeline quote delivered

- Alternative solutions presented if needed

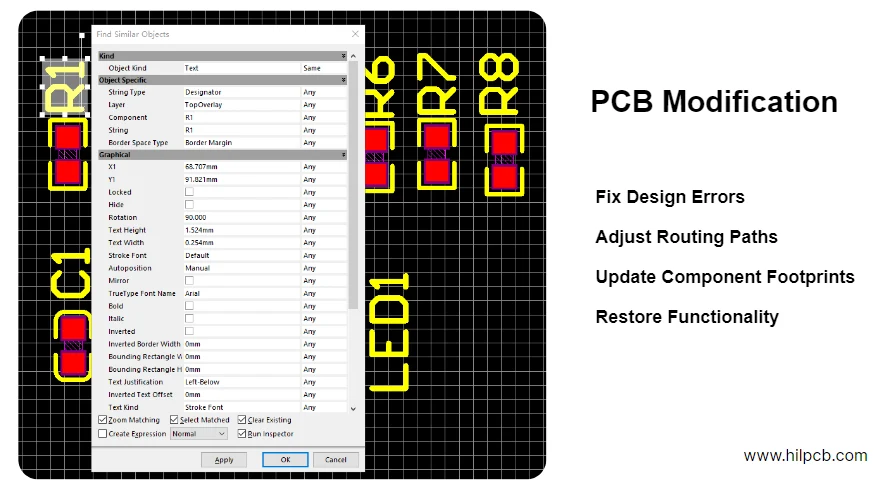

Hour 4-24: Modification Implementation

- CAD modifications with real-time client updates

- DRC verification and impedance checking

- Gerber generation with modification documentation

- Manufacturing file preparation and validation

Hour 24-48: Production & Verification

- Expedited PCB fabrication on dedicated line

- Priority assembly with your components

- Functional testing per your specifications

- Overnight shipping to your facility

PCB Modification Cost Structure (No Hidden Surprises)

Engineering Modification Fees:

- Simple modifications (≤10 net changes): $500-800

- Medium complexity (10-50 changes): $800-1,500

- Complex modifications (>50 changes): $1,500-3,000

- Emergency 24-hour service: +50% surcharge

Common modification examples with actual costs:

- Add test points for ICT coverage: $500 + fabrication

- Replace EOL component with alternate: $650 + fabrication

- Fix impedance mismatch on differential pairs: $950 + fabrication

- Resolve thermal issues with copper pour: $750 + fabrication

What's included: ✓ Engineering time and CAD work ✓ Electrical rule checking (ERC/DRC) ✓ Modification documentation package ✓ Gerber file generation and verification ✓ One round of client revisions

When PCB Modification Beats Redesign

Modification makes sense when:

- Time critical: Need solution in days, not weeks

- Limited scope: <20% of board requires changes

- Inventory exists: Components already purchased

- Tooling investment: Test fixtures and stencils must be preserved

- Certification valid: Changes don't trigger recertification

Real customer example: Automotive sensor manufacturer faced $2M inventory write-off when AEC-Q100 microcontroller became unavailable. Redesign quote: $45,000 and 12 weeks. Our modification solution: $3,200 and 72 hours. Result: Saved inventory, maintained delivery schedule, avoided customer penalties.

For complete overhauls, our PCB redesign service provides comprehensive updates. If you need technology modernization, explore PCB upgrade options. For cost analysis, request a detailed PCB quote comparison.

FAQ: PCB Modification Services

Q: Can you modify boards without original design files? A: Yes. We reverse-engineer from physical samples using X-ray, delayering, and optical scanning. Add 24-48 hours for reverse engineering.

Q: What if modification doesn't solve the problem? A: Our 98% first-time success rate comes from thorough assessment. If modification fails, engineering fees credit toward redesign services.

Q: Do you handle high-speed (25+ Gbps) modifications? A: Yes. We maintain impedance control within ±5% during modifications using field solvers and TDR verification.

Q: Can modifications maintain UL/CE certification? A: Most minor modifications don't affect certification. We provide detailed change documentation for submission to certification bodies.

Q: What's your minimum order for modified boards? A: No minimum for prototypes. Most modifications run 5-50 pieces for validation before volume production.