When a major automotive manufacturer needed assembly line control system upgrades, their specification contained one critical phrase: "Zero unplanned downtime tolerance." This requirement drives every aspect of PLC PCB design and manufacturing—from component selection through final testing and certification.

Programmable Logic Controllers represent the nervous system of modern industrial automation, controlling everything from simple conveyors to complex chemical processes. The PCBs inside these systems must deliver decades of reliable operation under conditions that would destroy consumer electronics.

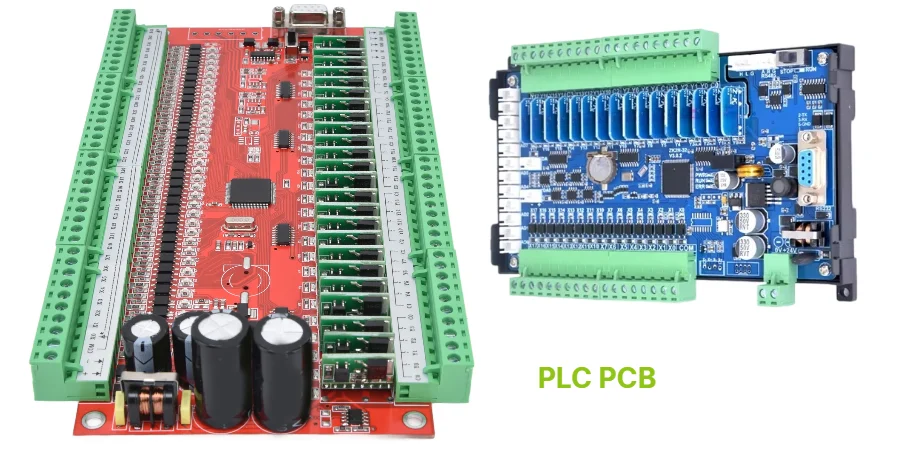

PLC I/O Module PCB Design and Interface Circuits

Input/Output modules form the critical interface between PLC control systems and field devices. PCB design must handle diverse signal types while providing robust isolation and protection against industrial electrical environments.

Digital Input Module Design: Digital inputs handle 24VDC signals with noise filtering and isolation. Input circuits use optocouplers for 2500V isolation between field and logic circuits. Input impedance standardized at 7mA nominal current ensures compatibility with various field devices.

Digital Output Implementation: Output modules provide switching for field devices using relay contacts or solid-state switches. Transistor outputs offer faster switching but require careful inductive load selection. Relay outputs provide better isolation and higher current handling with limited switching speed.

Analog Signal Processing: Analog modules handle industrial signals including 4-20mA current loops, 0-10V voltage signals, and thermocouple inputs. ADC resolution typically ranges 12-16 bits with 0.1% accuracy over industrial temperature ranges. Common-mode rejection prevents ground loop interference in current loops.

Protection and Isolation: All I/O circuits require robust protection against voltage transients, electrostatic discharge, and reverse polarity. Surge protection devices and transorbs protect against electrical faults, while fuses provide overcurrent protection with trip indication.

Industrial Communication PCB Interfaces

Modern PLC systems rely on robust communication interfaces for factory automation network integration. PCB design must support multiple protocols while maintaining electromagnetic compatibility and electrical isolation.

Ethernet Integration: Standard Ethernet provides enterprise network connectivity, while industrial protocols like EtherNet/IP and PROFINET enable real-time field device communication. PCB design includes isolation transformers and surge protection for industrial environments.

Fieldbus Interface Implementation: Traditional protocols including PROFIBUS, DeviceNet, and CANopen require specialized interface circuits. Each protocol has specific electrical requirements for signal levels, termination, and isolation with protocol-specific connectors and cable management.

Serial Communication Design: RS-232, RS-485, and RS-422 interfaces provide legacy device connectivity. RS-485 networks require proper termination and biasing for reliable long-distance communication. Isolation prevents ground loops in industrial installations.

Modular Communication Architecture: Modern PLCs use modular designs where communication interfaces are separate PCB modules. This enables application-specific customization while maintaining common control platforms. Hot-swappable modules require careful connector design and ESD protection.

Industrial-Grade PCB Manufacturing Standards

PLC PCBs must meet stringent manufacturing standards ensuring reliable operation in harsh industrial environments over extended lifespans. Material selection, assembly processes, and quality control all contribute to industrial-grade reliability.

Material Requirements: Industrial applications require high-Tg PCB materials with enhanced thermal stability and mechanical strength. Glass transition temperatures above 170°C ensure dimensional stability during thermal cycling. FR4 PCB substrates meet UL94 V-0 flame retardant requirements for safety applications.

Construction Specifications: Multilayer PCB designs provide dedicated power and ground planes for clean signal distribution. Heavy copper construction (2-6oz) handles high currents while maintaining acceptable voltage drops with redundant paths for critical power rails.

Surface Finish Selection: HASL provides excellent solder joint reliability and environmental resistance for industrial applications. ENIG offers superior planarity for fine-pitch components with better corrosion resistance in humid environments.

Quality Control Processes: Industrial PCB assembly requires controlled processes with statistical monitoring. Every PLC PCB undergoes comprehensive electrical testing including in-circuit testing, functional testing, and boundary scan verification. Automated optical inspection verifies assembly quality before functional testing.

Environmental Testing and Reliability Validation

PLC systems must operate reliably across extreme environmental conditions over operational lifespans measured in decades. Comprehensive testing validates design margins and identifies potential failure modes.

Temperature Performance: PLC PCBs maintain operation across -20°C to +70°C ambient temperatures while handling internal heat generation. Accelerated thermal cycling simulates years of daily temperature variations validating solder joint reliability and component stability.

Humidity and Corrosion Resistance: Industrial environments expose systems to humidity levels approaching 95% without condensation. Salt spray and mixed flowing gas testing validate resistance to corrosive environments in chemical processing and marine applications.

Mechanical Robustness: Installation near heavy machinery subjects systems to continuous vibration and shock loads. Testing per IEC 60068 standards validates mechanical design integrity under industrial vibration conditions with proper component mounting techniques.

EMC Validation: PLC systems must operate in electromagnetically noisy environments while limiting electromagnetic emissions. Testing includes immunity against external interference and emission verification for industrial standard compliance.

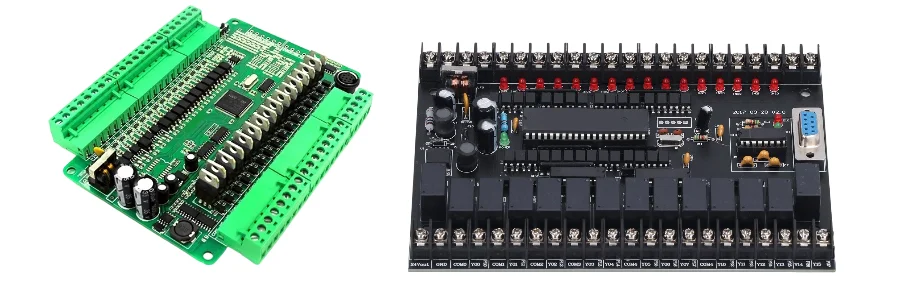

PLC CPU and Processing Module Design

The central processing unit implements control algorithms while managing communication with I/O modules and external systems. CPU module design balances processing performance with industrial reliability requirements.

Processor Selection: Industrial microcontrollers must operate across extended temperature ranges with enhanced electromagnetic immunity. ARM Cortex processors offer excellent performance while specialized industrial processors provide integrated PLC peripherals.

Memory Architecture: PLC systems require volatile RAM for program execution and non-volatile memory for program storage and data logging. FRAM or EEPROM provides retentive data storage, while battery backup maintains RAM contents during power interruptions.

Real-Time Performance: PLC algorithms require deterministic execution with scan times measured in milliseconds. Real-time operating systems ensure consistent timing performance, while hardware timers provide precise timing for critical functions.

Communication Processing: Modern PLCs handle multiple protocols simultaneously while maintaining real-time control performance. Dedicated communication processors or hardware acceleration offload communication from main control processors.

Power Supply Design for Industrial PLCs

PLC power supplies provide clean, stable power across wide input ranges while withstanding electrical disturbances common in industrial environments. Power design significantly affects overall system reliability and electromagnetic compatibility.

Input Conditioning: Industrial supplies handle input voltage variations of ±15% while maintaining regulated outputs. Input filters suppress conducted emissions and provide transient immunity. Power factor correction improves efficiency and reduces harmonic distortion.

Multi-Rail Architecture: PLC systems require multiple voltage rails including 24VDC for field devices, 5VDC for logic circuits, 3.3VDC for microprocessors, and isolated supplies for communication interfaces. Each rail requires appropriate regulation and filtering.

Safety and Monitoring: Safety applications may require reinforced isolation between input power and control circuits. Voltage monitoring detects undervoltage and overvoltage conditions affecting system operation. Current monitoring enables load diagnostics and preventive maintenance.

Modern PLC systems often utilize backplane PCB architectures for modular construction and reliable inter-module communication. Our small batch assembly services accommodate prototype development and specialized PLC configurations.

Frequently Asked Questions

Q: What makes PLC PCBs different from standard industrial PCBs? PLC PCBs require modular architectures, extensive I/O interfaces, real-time communication capabilities, and compliance with industrial automation standards like IEC 61131 with enhanced environmental resistance.

Q: How long do PLC PCBs last in industrial environments? Well-designed PLC PCBs achieve 15-20 year operational lifespans with proper maintenance. Success factors include industrial-grade components, robust environmental protection, and conservative electrical/thermal design margins.

Q: What environmental testing is required for PLC certification? Comprehensive testing includes temperature cycling (-25°C to +70°C), humidity testing (95% RH), vibration/shock testing per IEC 60068 standards, and electromagnetic compatibility per IEC 61000 standards.

Q: How do you ensure component availability for long PLC lifecycles? Strategic component selection emphasizes long-term availability roadmaps, multiple source options, and automotive-grade alternatives. Supplier partnerships and inventory management ensure continued production capability.

Q: What communication protocols are becoming standard? Ethernet-based protocols like EtherNet/IP and PROFINET increasingly dominate due to IT infrastructure compatibility. Traditional fieldbus protocols remain important for legacy integration and specialized applications.