Rogers 4350B represents a breakthrough in hydrocarbon ceramic laminate technology, specifically engineered for millimeter-wave and high-frequency applications demanding exceptional electrical performance. At Highleap PCB Factory, our specialized Rogers 4350B manufacturing processes leverage advanced fabrication techniques to deliver PCBs that maintain precise electrical characteristics across demanding frequency ranges from DC to 40+ GHz, ensuring optimal performance in critical RF and microwave systems.

The unique glass microfiber reinforcement structure of Rogers 4350B, combined with its proprietary low-loss dielectric formulation, delivers a dielectric constant (Dk) of 3.48 ± 0.04 at 10 GHz with exceptional frequency stability. The material's dissipation factor (Df) of 0.0037 at 10 GHz ensures minimal signal attenuation, making it the preferred choice for 5G infrastructure, automotive radar, and satellite communication systems where phase accuracy and low insertion loss are paramount.

Rogers 4350B Material Engineering and Electrical Characteristics

Rogers 4350B exhibits superior electrical stability with less than 2% dielectric constant variation from 1 MHz to 40 GHz, critical for broadband applications requiring consistent impedance characteristics. The material's low coefficient of thermal expansion (CTE) of 10 ppm/°C in the X-Y plane and 32 ppm/°C in the Z-axis provides exceptional dimensional stability during thermal cycling, essential for automotive radar applications operating from -40°C to +150°C.

The glass transition temperature (Tg) exceeding 280°C enables lead-free assembly processes without material degradation, while the thermal conductivity of 0.69 W/m/K facilitates efficient heat dissipation in power amplifier applications. Water absorption remains below 0.04%, significantly reducing dielectric constant drift in humid environments and ensuring long-term reliability in outdoor telecommunications infrastructure.

Rogers 4350B's isotropic properties minimize skew in differential pair routing, crucial for high-speed digital applications. The material's low loss tangent combined with smooth copper surface (Rz < 3.0 μm) reduces conductor loss at millimeter-wave frequencies, enabling efficient signal transmission in 77-81 GHz automotive radar and 24-30 GHz 5G beamforming networks.

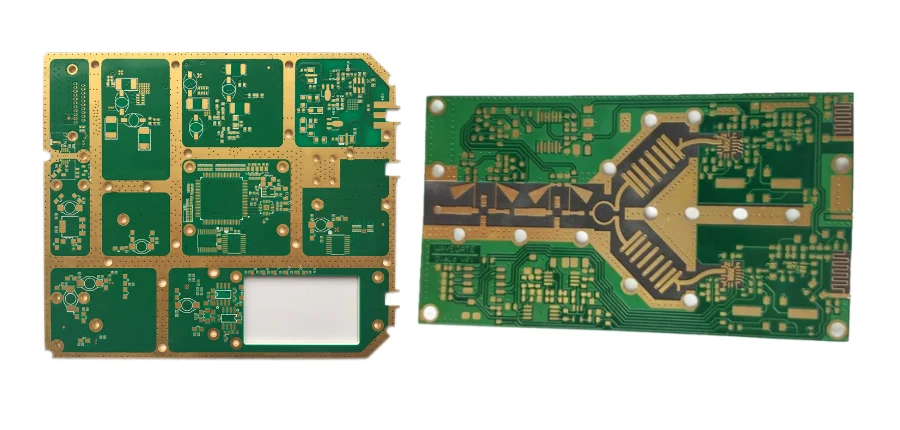

Advanced Rogers 4350B Fabrication Processes and Manufacturing Controls

Rogers 4350B processing demands specialized drilling parameters optimized for its ceramic-filled composition. Our proprietary drill programs utilize carbide bits with 130-degree point angles, operating at speeds between 120-180 SFM with feed rates of 2-6 IPM depending on hole diameter and aspect ratio. This approach minimizes ceramic particle pullout and ensures consistent hole wall quality throughout multilayer stackups.

High-frequency PCB lamination processes for Rogers 4350B employ controlled heating profiles reaching 370°C at 350 PSI, with 75-minute dwell times ensuring complete resin cure without void formation. The cooling cycle follows a precise 1.5°C per minute rate to minimize internal stress and prevent warpage in complex multilayer configurations.

Chemical processing of Rogers 4350B requires modified etchant formulations accounting for the substrate's enhanced chemical resistance. We utilize plasma desmear processes operating at 250W power with optimized oxygen/CF4 chemistry to remove drilling debris while activating surfaces for reliable electroless copper adhesion. Via hole plating employs high throwing power chemistry ensuring complete coverage in aspect ratios up to 10:1.

Controlled Impedance Engineering for Rogers 4350B Applications

Impedance control in Rogers 4350B PCBs requires precise electromagnetic field modeling accounting for frequency-dependent dielectric properties and conductor surface roughness effects. For 50-ohm microstrip transmission lines on 0.508mm Rogers 4350B with 35μm copper, trace widths typically measure 1.45mm, accounting for manufacturing tolerances and surface roughness compensation at frequencies above 20 GHz.

Multilayer PCB designs utilizing Rogers 4350B benefit from our advanced field solving capabilities employing 3D electromagnetic simulation tools. Stripline configurations require careful reference plane spacing optimization, with typical 50-ohm striplines measuring 0.75mm width between planes spaced 0.508mm apart, compensated for via stub effects and layer-to-layer registration tolerances.

Differential pair routing strategies for Rogers 4350B follow stringent design rules maintaining 100-ohm impedance with minimal skew. Edge-coupled pairs utilize 0.85mm trace widths with 0.18mm spacing, while broadside-coupled configurations employ 1.1mm traces separated by 0.254mm dielectric thickness, accounting for interlayer dielectric variations and copper weight tolerances.

Rogers 4350B Layer Stackup Optimization and Via Architecture

Complex multilayer configurations using Rogers 4350B require strategic material selection balancing performance and cost. Hybrid stackups combining Rogers 4350B with compatible dielectrics provide cost optimization while maintaining critical layer performance. Typical 10-layer stackups employ Rogers 4350B for outer layers and primary signal layers, with FR4-based prepregs for internal power distribution where high-frequency performance is less critical.

Micro-via technology in Rogers 4350B applications utilizes laser drilling with 0.1mm diameter holes maintaining 1:1 aspect ratios to minimize parasitic effects above 30 GHz. Back-drilling of through-hole vias eliminates resonant stubs affecting broadband performance, with our precision back-drilling capabilities achieving ±0.05mm depth control ensuring consistent electrical performance across production lots.

Sequential lamination processes for blind and buried via structures require careful thermal budget management to prevent Rogers 4350B degradation. Each sub-assembly undergoes independent drilling, plating, and inspection before final lamination, ensuring reliable interconnection without compromising base material properties or dimensional accuracy.

High-Power Rogers 4350B Thermal Management and Assembly Optimization

Power amplifier applications utilizing Rogers 4350B demand sophisticated thermal management strategies due to the material's moderate thermal conductivity. Thermal via arrays with 0.15mm diameter holes spaced at 0.4mm intervals provide efficient heat transfer paths, reducing junction-to-case thermal resistance by 50-70% compared to solid copper fills alone.

SMT assembly processes for Rogers 4350B substrates require optimized reflow profiles limiting peak temperatures to 250°C with maximum heating rates of 2°C/second to prevent thermal shock. Vapor phase soldering provides uniform heating distribution, critical for maintaining substrate integrity while achieving reliable solder joint formation on fine-pitch components.

Component placement accuracy becomes critical on Rogers 4350B substrates due to the material's smooth surface finish and thermal properties. Our automated placement systems maintain ±0.03mm tolerances for 0201 components and ±0.025mm for flip-chip devices, ensuring optimal solder joint geometry and electrical performance in high-frequency circuits.

Rogers 4350B Quality Assurance and Advanced Testing Protocols

Quality control for Rogers 4350B PCBs employs specialized metrology addressing the material's unique electrical properties. Dielectric constant verification utilizes stripline resonator test structures integrated into production panels, enabling statistical process control with ±1% measurement accuracy across frequency ranges from 1-40 GHz.

Insertion loss characterization employs calibrated vector network analysis with precision test fixtures compensating for probe-to-circuit transitions. Our testing protocols verify performance parameters including return loss, insertion loss, and group delay across operational frequency bands, ensuring compliance with stringent RF system requirements.

Environmental qualification testing for Rogers 4350B assemblies follows modified IPC standards accounting for automotive and aerospace requirements. Thermal cycling from -65°C to +150°C with 1500 cycle minimum validates long-term reliability, while humidity testing at 85°C/85% RH for 1000 hours confirms moisture resistance performance.

Advanced Rogers 4350B Applications and Industry Solutions

Automotive radar systems operating at 77-81 GHz represent the largest growth market for Rogers 4350B substrates. These applications demand exceptional phase stability and low loss performance in compact antenna arrays subjected to extreme temperature cycling. Our turnkey assembly services for radar modules include specialized RF testing to 110 GHz using advanced measurement systems.

5G millimeter-wave infrastructure utilizes Rogers 4350B for beamforming networks and power amplifier modules operating from 24-30 GHz. The material's stable electrical properties enable phase-matched transmission line networks achieving ±1.5° phase tolerance across temperature ranges, critical for massive MIMO base station performance.

Satellite communication systems increasingly adopt Rogers 4350B for Ka-band applications from 26.5-40 GHz, where the material's low outgassing properties and radiation resistance meet space qualification requirements. Our manufacturing processes accommodate stringent documentation and material traceability standards required for space-grade applications.

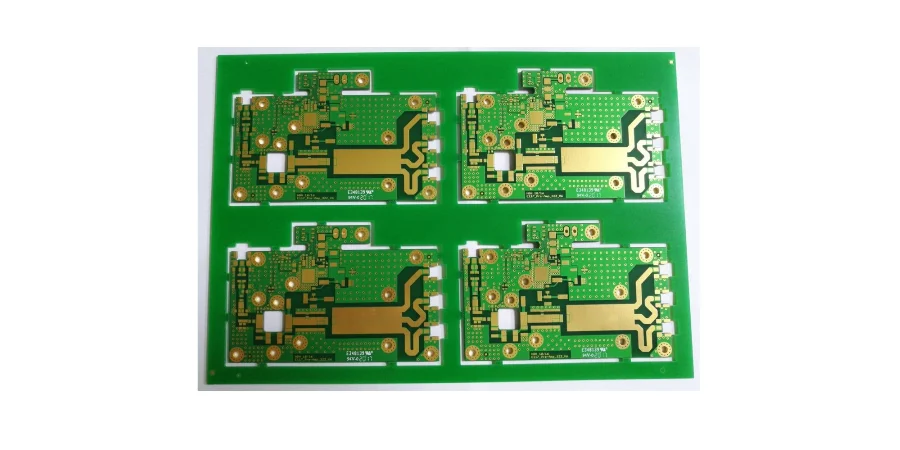

Cost-Effective Rogers 4350B Manufacturing Strategies and Supply Chain Optimization

Rogers 4350B material costs can be optimized through intelligent panel utilization and hybrid stackup strategies. Mixed material designs utilizing Rogers 4350B only for performance-critical layers reduce overall material costs by 35-55% while maintaining electrical specifications. Our design optimization services identify cost reduction opportunities without compromising performance requirements.

Small batch assembly capabilities enable cost-effective Rogers 4350B prototyping with maintained inventory of standard thicknesses minimizing lead times for development projects. Volume pricing structures for production quantities provide significant cost advantages while preserving specialized processing requirements and quality standards.

Strategic supplier partnerships ensure consistent Rogers 4350B material availability and quality. Our procurement processes include incoming material testing and certification, maintaining lot-to-lot traceability throughout the manufacturing process. This approach ensures supply chain reliability while optimizing inventory investment and reducing project risk.

Conclusion and Manufacturing Excellence

Rogers 4350B PCB manufacturing represents the convergence of advanced materials science and precision manufacturing processes, demanding specialized expertise and equipment investments to achieve optimal electrical performance. Highleap PCB Factory's comprehensive Rogers 4350B capabilities encompass the complete manufacturing spectrum from initial design consultation through final assembly and qualification testing. Our commitment to process innovation, quality excellence, and technical support ensures successful implementation of Rogers 4350B solutions for the most demanding millimeter-wave and high-frequency applications, backed by comprehensive documentation, ongoing technical support, and supply chain reliability that extends throughout the entire product development and production lifecycle.