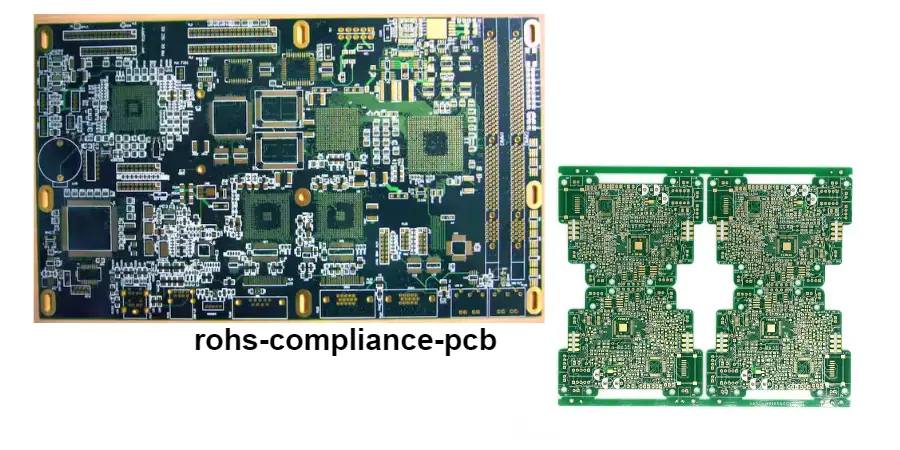

Global electronics markets demand environmental compliance—regulatory non-compliance can trigger product seizures, market restrictions, and financial penalties. RoHS compliance PCB manufacturing addresses these requirements through systematic elimination of hazardous substances and lead-free processes ensuring unrestricted global market access.

HILPCB maintains comprehensive RoHS compliance certification with lead-free manufacturing processes eliminating restricted hazardous substances while maintaining superior electrical performance and reliability.

RoHS Compliance PCB Structure and Regulatory Requirements

RoHS compliance PCB manufacturing addresses comprehensive restrictions on hazardous substances including lead, mercury, cadmium, hexavalent chromium, and brominated flame retardants.

The fundamental RoHS compliance requirements include:

- Complete elimination of lead from solder alloys, surface finishes, and component terminations

- Restriction of mercury, cadmium, and hexavalent chromium in all manufacturing processes

- Control of PBB and PBDE in flame retardant systems

- Lead-free surface finishes including HASL, ENIG, and OSP for single-double layer PCB applications

- Flex PCB manufacturing with RoHS-compliant adhesives and coverlays

- Heavy copper PCB processes utilizing lead-free plating chemistries

RoHS compliance extends beyond individual PCB manufacturing to encompass complete supply chain management including component sourcing, material certification, and process validation ensuring consistent regulatory compliance throughout production and global distribution.

Specialized Lead-Free Manufacturing and Process Optimization

Our RoHS compliance PCB manufacturing incorporates advanced lead-free technologies and process optimization that deliver superior performance while maintaining complete environmental regulatory compliance:

- Lead-Free Solder Alloy Systems: SAC (Tin-Silver-Copper) alloys optimized for reliability and thermal performance

- Advanced Surface Finish Technologies: ENIG, HASL lead-free, and organic solderable preservative (OSP) processes

- Environmental Process Controls: Systematic elimination of restricted substances throughout manufacturing workflows

- Supply Chain Compliance Management: Comprehensive supplier qualification and material certification programs

- Documentation and Traceability: Complete compliance documentation supporting regulatory audits and customer requirements

- Large volume assembly with RoHS compliance: Scalable production maintaining environmental compliance across all volume requirements

Quality management systems for RoHS compliance incorporate risk-based approaches that monitor and control potential contamination sources while ensuring consistent regulatory compliance throughout all manufacturing operations and supply chain partnerships.

Supply Chain Management and Material Certification for RoHS Compliance

Achieving consistent RoHS compliance requires comprehensive supply chain management that addresses material sourcing, supplier qualification, and continuous monitoring of potential contamination sources throughout global supply networks and manufacturing operations.

Advanced Supplier Qualification and Management

RoHS compliance demands systematic supplier evaluation ensuring consistent regulatory compliance throughout global supply chains.

- Supplier Compliance Certification: Comprehensive qualification requiring suppliers to demonstrate RoHS compliance through testing and documentation

- Material Declaration Management: Systematic collection of material composition data including substance declarations and compliance certificates

- Audit and Verification Programs: Regular supplier audits confirming ongoing compliance while identifying risks

- Corrective Action and Continuous Improvement: Structured procedures for addressing compliance issues with immediate corrective action

Material Testing and Validation Systems

Comprehensive testing ensures accurate identification and control of restricted substances throughout manufacturing processes.

- X-Ray Fluorescence (XRF) Screening: High-throughput screening for detecting restricted heavy metals in materials

- Chemical Analysis and Confirmation: Advanced analytical techniques for definitive identification of restricted substances

- Process Contamination Monitoring: Systematic monitoring for potential cross-contamination from legacy equipment

- Statistical Sampling and Quality Control: Risk-based sampling optimized for compliance verification

Documentation and Regulatory Reporting

RoHS compliance requires comprehensive documentation supporting regulatory reporting and customer declarations.

- Compliance Declaration Systems: Automated systems generating compliance declarations and certificates

- Regulatory Database Management: Comprehensive tracking of regulatory requirements across global markets

- Audit Trail and Traceability: Complete documentation supporting regulatory audits and investigations

- Customer Communication and Support: Proactive communication for regulatory changes and compliance status updates

RoHS Compliance Applications and Global Market Requirements

RoHS compliance PCB manufacturing serves global markets with diverse regulatory requirements that demand systematic environmental compliance for unrestricted market access and customer acceptance across international distribution networks.

European Union Market Access: RoHS directive compliance provides mandatory market access for electronic products sold in European markets, with enforcement procedures including product testing, market surveillance, and penalties for non-compliance. Consistent compliance ensures unrestricted distribution throughout EU member countries.

Global Regulatory Harmonization: Many countries including China, Japan, and South Korea have adopted RoHS-similar regulations creating global demand for compliant products. Systematic compliance addresses multiple regulatory requirements through unified manufacturing processes and documentation systems.

Customer Specification Requirements: Major OEMs and brand owners require RoHS compliance as standard procurement requirement regardless of regulatory mandates. Supplier qualification procedures increasingly demand demonstrated environmental compliance with comprehensive documentation and ongoing monitoring.

Insurance and Liability Management: Environmental compliance reduces liability risks associated with product recalls, regulatory violations, and environmental damage claims. Insurance requirements increasingly consider environmental compliance as risk management factor affecting coverage and premium costs.

Advanced Environmental Compliance Technologies and Innovation

Environmental compliance leadership requires continuous advancement in materials, processes, and management systems that exceed current regulatory requirements while anticipating future environmental regulations and customer expectations.

Next-Generation Lead-Free Technologies:

- Advanced solder alloy development providing superior reliability and thermal performance compared to traditional lead-containing systems

- Nano-technology approaches enhancing mechanical properties and reliability of lead-free solder joints

- Small batch assembly optimization for lead-free processes maintaining quality and efficiency

- Bio-based surface finish alternatives providing environmental benefits beyond RoHS compliance requirements

Integrated Compliance Management Systems:

- Real-time monitoring systems providing continuous compliance verification throughout manufacturing operations

- Predictive analytics identifying potential compliance risks before they affect production or product quality

- Blockchain-based traceability systems providing immutable compliance documentation throughout supply chains

- Artificial intelligence applications optimizing compliance procedures while minimizing testing and documentation overhead

Sustainable Manufacturing Integration:

- Circular economy principles incorporating material recovery and recycling throughout manufacturing processes

- Energy-efficient processes reducing carbon footprint while maintaining regulatory compliance and product quality

- Water conservation and waste minimization programs addressing broader environmental impact beyond RoHS requirements

- Life-cycle assessment integration optimizing environmental performance throughout product lifecycles

Why Choose HILPCB for RoHS Compliance PCB Manufacturing

Environmental regulatory compliance requires manufacturing partners with comprehensive compliance expertise, proven processes, and commitment to continuous improvement that ensures reliable market access across global distribution networks. HILPCB delivers RoHS compliance manufacturing with advanced environmental technologies and management systems that exceed regulatory requirements while maintaining superior product performance.

Our RoHS compliance certification represents proven environmental manufacturing through systematic implementation of lead-free processes, hazardous substance controls, and comprehensive supply chain management. Compliance systems address all aspects of environmental manufacturing from material sourcing through final product delivery, ensuring consistent regulatory performance across all production volumes and global markets.

Technical expertise encompasses advanced lead-free technologies, environmental testing, and regulatory compliance management that ensures optimal environmental performance while maintaining electrical and mechanical properties required for demanding applications. From prototype development through volume production, we deliver environmental excellence that supports unrestricted global market access and customer satisfaction.

Frequently Asked Questions — RoHS Compliance PCB

Q1: What substances are restricted under RoHS directive?

A: RoHS restricts lead, mercury, cadmium, hexavalent chromium, polybrominated biphenyls (PBB), and polybrominated diphenyl ethers (PBDE) in electronic products, with additional restrictions on phthalates in some applications.

Q2: How does lead-free soldering affect PCB reliability?

A: Modern lead-free solder alloys provide excellent reliability through optimized processing parameters and advanced alloy formulations, often exceeding the performance of traditional lead-containing systems in many applications.

Q3: What documentation is required for RoHS compliance?

A: Comprehensive documentation includes material declarations, test reports, supplier certificates, process validation records, and compliance declarations that demonstrate systematic environmental compliance throughout manufacturing.

Q4: How do you ensure ongoing RoHS compliance?

A: Systematic supplier management, regular material testing, process monitoring, and continuous training programs ensure consistent compliance while adapting to evolving regulatory requirements and customer specifications.

Q5: Can RoHS compliance be maintained for complex PCB designs?

A: Yes, advanced lead-free technologies and specialized processes successfully address complex designs including high-density interconnects, high-frequency applications, and thermal management requirements while maintaining complete regulatory compliance.

Q6: What are the cost implications of RoHS compliance?

A: While initial implementation may require investment in new processes and materials, RoHS compliance typically provides long-term cost benefits through unrestricted market access, reduced liability risks, and improved customer acceptance.