When a critical automotive radar system fails during final testing, engineers face a nightmare scenario: identifying microscopic defects in complex multilayer PCBs worth thousands of dollars each. Traditional continuity testing reveals the board is "functional," but performance data shows intermittent failures under real-world conditions. The answer lies in advanced diagnostics that can peer into the invisible world of signal propagation.

At Highleap PCB Factory (HILPCB), we utilize Time Domain Reflectometry (TDR) testing as the cornerstone of our quality control process. This technology transforms invisible electrical problems into precise, actionable data—enabling us to detect manufacturing defects, validate design performance, and ensure long-term reliability before products reach the field.

The Science Behind TDR Testing Technology

TDR testing operates on a fundamental principle: when fast electrical pulses encounter changes in transmission line characteristics, they create reflections that reveal the exact nature and location of discontinuities. This technology transforms PCB traces into detailed maps of electrical behavior, revealing problems invisible to conventional testing methods.

Pulse Propagation Analysis: TDR instruments generate precisely timed electrical pulses with rise times measured in picoseconds. These pulses travel along PCB traces at approximately 50-70% the speed of light, depending on the dielectric material. When encountering impedance changes, opens, shorts, or other discontinuities, portions of the pulse energy reflect back to the instrument while the remainder continues forward.

Spatial Resolution Capabilities: Modern TDR equipment can resolve discontinuities to within millimeters on a PCB trace. This spatial precision enables identification of specific manufacturing defects such as via transitions, solder joint problems, or material inconsistencies. The technique is particularly valuable for high-speed PCB designs where signal integrity directly impacts system performance.

Impedance Characterization: TDR testing provides continuous impedance profiles along trace lengths, revealing variations that affect signal quality. Unlike simple resistance measurements, TDR captures the complex impedance behavior that determines high-frequency performance in modern electronic systems.

Manufacturing Process Integration for Quality Excellence

Implementing TDR testing effectively requires integration throughout the manufacturing process, not just as a final inspection step. This comprehensive approach ensures quality is built into every stage of production.

Strategic Quality Control Implementation

We implement a systematic approach that leverages TDR testing capabilities at multiple manufacturing stages to maximize defect detection and minimize production costs.

1. Pre-Production Validation

Before committing to full production runs, we perform comprehensive TDR characterization on prototype boards to establish baseline performance standards. This process validates design assumptions, confirms manufacturing feasibility, and establishes quality benchmarks for production monitoring.

- Design Verification: Confirms impedance targets are achievable with selected materials and processes.

- Process Optimization: Identifies manufacturing parameters that affect electrical performance.

- Benchmark Establishment: Creates reference standards for production quality control.

2. In-Process Monitoring

TDR testing during key manufacturing steps enables immediate detection of process variations before they propagate through subsequent operations. Our automated testing systems can identify trends in electrical performance that indicate tool wear, material variations, or environmental changes.

- Real-Time Process Control: Immediate feedback enables process adjustments during production.

- Trend Analysis: Statistical monitoring identifies gradual changes before they affect quality.

- Cost Reduction: Early detection prevents expensive rework on completed assemblies.

3. Final Quality Assurance

Comprehensive TDR testing validates that finished products meet all electrical specifications and will perform reliably throughout their operational lifetime. This testing goes beyond simple pass/fail criteria to provide detailed performance documentation.

- Performance Documentation: Detailed electrical characterization for customer records.

- Reliability Prediction: Identifies marginal products that might fail prematurely.

- Compliance Verification: Ensures products meet industry standards and specifications.

Advanced Applications in Electronics Manufacturing

TDR testing extends far beyond basic quality control, enabling sophisticated analysis of complex electrical behaviors in modern electronic systems.

Failure Analysis and Diagnostics: When electronic systems fail in the field, TDR testing provides powerful diagnostic capabilities. The technique can identify the exact location of failures such as electromigration damage, thermal stress fractures, or corrosion-induced opens. This information guides repair strategies and helps prevent similar failures in future designs.

Multilayer PCB Characterization: Complex multilayer designs present unique challenges for electrical testing. TDR testing can characterize inner layer traces that are inaccessible to traditional probing methods, validating signal integrity through the complete layer stack.

Material Property Evaluation: TDR testing reveals how different PCB materials affect signal propagation. This information guides material selection for specific applications and helps optimize designs for maximum performance and reliability.

Specialized Testing for Critical Applications

Different industries and applications require customized TDR testing approaches to address specific performance requirements and failure modes.

Aerospace and Defense Systems

Military and aerospace applications demand exceptional reliability under extreme conditions. Our TDR testing protocols for these applications include temperature cycling, humidity exposure, and mechanical stress testing to validate performance across operational envelopes.

Automotive Electronics

Modern vehicles incorporate increasingly complex electronic systems that must operate reliably for decades. TDR testing validates signal integrity in engine control units, safety systems, and autonomous driving components where failure is not an option.

Medical Device Validation

Medical electronics require exceptional reliability and consistent performance. TDR testing ensures that critical monitoring and life support systems maintain signal integrity throughout their operational lifetime.

Industrial Control Systems

Manufacturing automation and process control systems demand consistent performance in harsh industrial environments. TDR testing validates electrical performance under conditions including electromagnetic interference, temperature extremes, and mechanical vibration.

HILPCB — Advanced TDR Testing Solutions

1. Our Testing Philosophy

We approach TDR testing as an integral part of quality manufacturing, not just an inspection step. Our comprehensive testing methodology combines advanced instrumentation with deep understanding of PCB physics to provide actionable insights that improve both current production and future designs. Every test procedure is designed to maximize information content while minimizing testing time and cost.

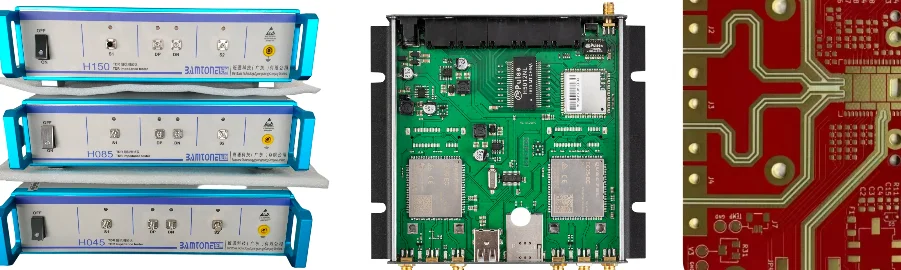

2. Our Technical Capabilities

- High-Resolution TDR Systems (DC—50 GHz) — Detecting discontinuities smaller than 1mm with calibrated accuracy traceable to national standards.

- Automated Production Testing — High-throughput testing systems integrated with manufacturing workflow for 100% production coverage.

- Custom Test Fixture Development — Application-specific testing solutions for complex PCB geometries and connector interfaces.

- Statistical Process Analysis — Advanced data analysis identifying trends and correlations in electrical performance data.

- Flex PCB Testing Expertise — Specialized techniques for characterizing flexible circuits and rigid-flex assemblies.

3. Why Choose HILPCB

- Comprehensive Quality Integration — TDR testing integrated throughout manufacturing process for maximum defect detection efficiency.

- Advanced Instrumentation — State-of-the-art testing equipment maintained with regular calibration and upgrades.

- Expert Analysis Team — Experienced engineers who understand both PCB physics and practical manufacturing constraints.

From initial prototypes through high-volume production, our TDR testing capabilities ensure your critical electronics meet performance specifications and reliability requirements. Our engineering team works closely with customers to develop optimized testing strategies that balance thoroughness with production efficiency.

Frequently Asked Questions

Q: What defects can TDR testing detect that other methods miss? TDR testing can identify impedance variations, via transition problems, trace discontinuities, and material inconsistencies that don't affect DC connectivity but cause signal integrity issues in high-speed applications.

Q: How does TDR testing compare to network analyzer measurements? TDR provides spatial information about where problems occur along traces, while network analyzers characterize overall frequency response. Both techniques are complementary for complete electrical characterization.

Q: Can TDR testing be performed on assembled PCBs? Yes, TDR testing can characterize assembled boards, though component loading may affect measurements. We develop custom test procedures for specific assembly configurations and component types.

Q: What resolution can be achieved with TDR testing? Modern TDR systems can resolve discontinuities to within 1mm on typical PCB materials, with exact resolution depending on pulse rise time and dielectric properties of the substrate material.

Q: How does TDR testing affect production throughput? Our automated TDR testing systems are designed for high-throughput production environments, typically adding less than 30 seconds per board to the manufacturing cycle while providing comprehensive electrical validation.

Q: What documentation is provided with TDR testing results? We provide detailed test reports including impedance profiles, discontinuity locations, and statistical analysis of electrical performance, with all measurements traceable to calibrated standards for quality assurance purposes.