Electronic device fires in homes and facilities can cause property damage, injuries, and massive product recalls worth millions. UL 94V-0 PCB fire safety standards establish stringent flame retardant requirements that prevent fire propagation and ensure safe operation across diverse applications.

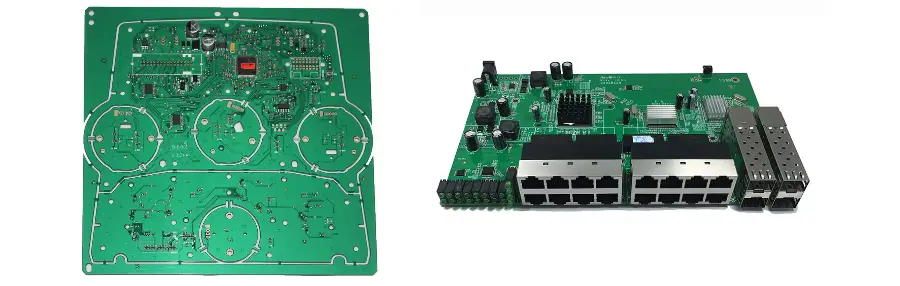

HILPCB manufactures UL 94V-0 certified PCBs with flame retardant materials and processes that ensure reliable fire resistance for consumer electronics, industrial equipment, and safety-critical applications.

Understanding UL 94V-0 PCB Fire Safety Requirements

UL 94V-0 PCB standards establish the most stringent flame retardant requirements for printed circuit board materials, ensuring rapid flame extinguishment and minimal fire propagation.

UL 94V-0 Standard Specifications: The V-0 classification requires test specimens to self-extinguish within 10 seconds after flame removal, show no flaming drips, and demonstrate total flame time under 50 seconds for five flame applications.

Fire Safety Mechanisms: UL 94V-0 materials incorporate flame retardant chemistries that interrupt combustion through thermal decomposition products, endothermic reactions, and char formation creating protective barriers.

Material Selection: FR4 PCB substrates achieving UL 94V-0 rating utilize specialized flame retardant additives while maintaining electrical and mechanical properties. High-Tg PCB materials combine elevated glass transition temperatures with UL 94V-0 performance.

Critical Applications: Consumer electronics, building systems, transportation equipment, and industrial machinery where component failures could lead to fire incidents.

Advanced Flame Retardant Materials and Manufacturing Technologies

UL 94V-0 PCB manufacturing requires specialized materials and processing techniques that maintain superior electrical and mechanical performance while providing exceptional fire resistance through advanced flame retardant technologies.

Specialized Material Systems for Fire Safety

Our UL 94V-0 PCB manufacturing incorporates advanced material technologies delivering superior fire resistance while maintaining optimal electrical and mechanical performance.

1. Advanced Flame Retardant Chemistry Integration

Modern UL 94V-0 materials utilize sophisticated flame retardant systems providing fire resistance without compromising electrical properties or environmental performance.

- Phosphorus-Based Flame Retardants: Environmentally preferred systems

- Nitrogen-Based Additives: Synergistic flame retardant enhancement

- Inorganic Flame Retardants: Mineral-based thermal stability

2. Specialized Substrate Manufacturing

Multilayer PCB construction with UL 94V-0 materials requires specialized lamination processes ensuring uniform flame retardant distribution while maintaining electrical and mechanical integrity.

- Controlled Lamination Processes: Optimized temperature and pressure profiles

- Uniform Fire Resistance: Consistent UL 94V-0 performance throughout layers

- Enhanced Reliability: Long-term stability under operating conditions

3. High-Temperature Performance Integration

Applications requiring both fire safety and elevated temperature operation utilize ceramic PCB and rogers PCB materials combining UL 94V-0 flame retardancy with superior thermal performance.

Fire Safety Testing and Certification Procedures

UL 94V-0 PCB certification requires comprehensive testing demonstrating consistent fire resistance performance across production lots and operating conditions.

Comprehensive UL 94 Testing Protocols

- Vertical Burning Test Procedures: Standardized flame application and measurement under controlled laboratory conditions

- Flame Spread and Extinction Timing: Precise measurement ensuring materials meet stringent UL 94V-0 timing requirements

- Dripping and Char Formation Assessment: Evaluation of material behavior during combustion

- Temperature and Environmental Conditioning: Testing across temperature and humidity ranges

Production Quality Control and Monitoring

- Incoming Material Certification: Comprehensive verification of flame retardant properties with compliance documentation

- Process Control Monitoring: Statistical monitoring of manufacturing processes affecting flame retardant properties

- Final Product Validation: Sample testing confirming UL 94V-0 performance with complete documentation

Environmental and Safety Considerations

- Halogen-Free PCB Development: Environmental-friendly flame retardant systems achieving UL 94V-0 performance

- Low Smoke and Toxicity: Materials minimizing smoke generation and toxic gas emission

- Worker Safety Protocols: Comprehensive safety procedures for handling flame retardant materials

Applications and Industry Requirements for UL 94V-0 PCB

UL 94V-0 PCB fire safety standards serve critical applications across industries where fire prevention and safety are paramount concerns affecting both regulatory compliance and liability management.

Consumer Electronics Safety: Home appliances, entertainment systems, and portable devices require UL 94V-0 materials to prevent fire incidents that could endanger users and property. Insurance requirements and product liability considerations drive adoption of the highest fire safety standards for consumer-facing electronic products.

Building and Infrastructure Systems: HVAC controls, lighting systems, and security equipment utilize UL 94V-0 PCBs to meet building code requirements and insurance standards for fire safety. These applications require consistent fire resistance performance throughout extended service intervals in occupied buildings.

Industrial and Manufacturing Equipment: Control systems, motor drives, and process equipment incorporate UL 94V-0 materials to prevent fire incidents that could disrupt operations and endanger workers. Industrial applications demand fire safety standards that address high-power operations and harsh environmental conditions.

Transportation and Automotive Systems: Vehicle electronics, railway systems, and aviation equipment require UL 94V-0 fire resistance to meet stringent safety regulations and prevent fire incidents in confined transportation environments where passenger safety is critical.

Advanced Fire Safety Technologies and Innovation

Fire safety leadership requires continuous innovation in flame retardant technologies that enhance safety performance while addressing environmental concerns and performance requirements.

Next-Generation Flame Retardant Systems:

- Development of bio-based flame retardants providing UL 94V-0 performance with enhanced environmental compatibility

- Nano-technology approaches that achieve superior fire resistance with minimal additive loading

- High-thermal PCB materials combining fire safety with enhanced thermal management capabilities

- Smart flame retardant systems that activate only under fire conditions

Integrated Safety Design Approaches:

- System-level fire safety design incorporating PCB fire resistance with circuit protection and thermal management

- Advanced modeling and simulation tools predicting fire safety performance in complex electronic systems

- Integration of fire safety requirements with electrical performance optimization

- Multi-functional materials providing fire resistance, EMI shielding, and thermal management

Environmental Fire Safety Solutions:

- Halogen-free flame retardant systems achieving UL 94V-0 performance with reduced environmental impact

- Recyclable flame retardant materials supporting circular economy principles

- Low-smoke, low-toxicity formulations enhancing safety performance during fire incidents

- Sustainable manufacturing processes minimizing environmental impact while maintaining fire safety standards

Why Choose HILPCB for UL 94V-0 PCB Manufacturing

Fire safety excellence in PCB manufacturing requires comprehensive technical expertise, certified materials, and proven manufacturing processes that consistently deliver UL 94V-0 performance. HILPCB combines advanced flame retardant technologies with rigorous quality control procedures that ensure reliable fire safety for the most demanding applications.

Our UL 94V-0 certification represents proven fire safety manufacturing through systematic implementation of flame retardant materials, controlled processing procedures, and comprehensive testing validation. Quality systems address all aspects of fire safety from material selection through final product delivery, ensuring consistent UL 94V-0 performance across all production volumes.

Technical expertise encompasses flame retardant material selection, fire safety testing, and application-specific optimization that ensures optimal fire resistance while maintaining electrical and mechanical performance requirements. From prototype development through volume production, we deliver fire safety excellence that protects products, users, and property throughout extended service life.

Frequently Asked Questions

Q: What does UL 94V-0 rating mean for PCB materials? UL 94V-0 represents the highest flame retardant classification, requiring materials to self-extinguish within 10 seconds after flame removal with no flaming drips and total burn time under 50 seconds.

Q: How does UL 94V-0 affect PCB electrical performance? Modern UL 94V-0 materials maintain excellent electrical properties including dielectric constant, loss tangent, and insulation resistance while providing superior fire resistance through advanced flame retardant technologies.

Q: Are UL 94V-0 PCBs required by regulations? Many applications require UL 94V-0 materials to meet building codes, insurance requirements, product safety standards, and regulatory approvals, particularly for consumer electronics and building systems.

Q: Can UL 94V-0 materials be halogen-free? Yes, advanced halogen-free flame retardant systems can achieve UL 94V-0 performance, addressing environmental concerns while maintaining the highest fire safety standards.

Q: How is UL 94V-0 performance verified during manufacturing? Systematic testing of incoming materials, process control monitoring, and final product validation ensure consistent UL 94V-0 performance with complete documentation supporting certification requirements.

Q: What applications benefit most from UL 94V-0 PCBs? Consumer electronics, building systems, industrial equipment, and transportation applications benefit from UL 94V-0 fire safety, particularly where fire incidents could endanger users or property.