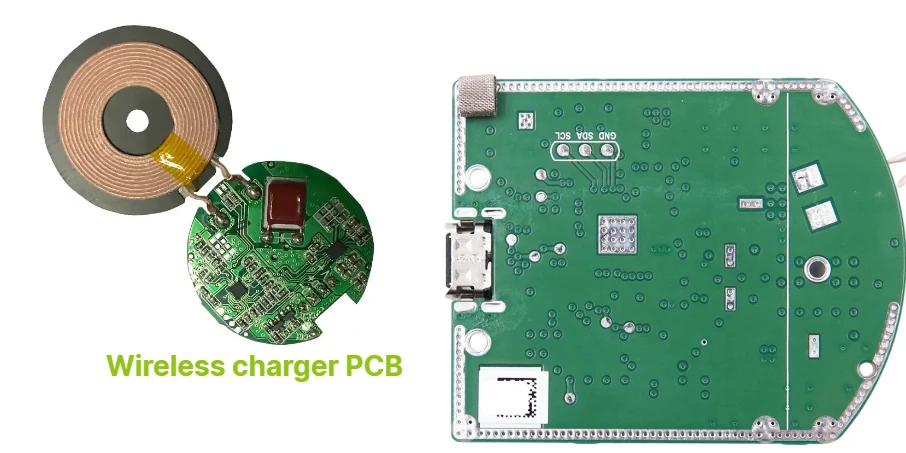

The wireless charging revolution has transformed how we power our devices - from smartphones and earbuds to electric vehicles and medical implants. Behind every efficient wireless charging experience lies a precisely engineered Wireless Charger PCB that manages complex electromagnetic fields, power conversion, and safety protocols.

At HILPCB, we manufacture advanced circuit boards serving diverse industries including power electronics, automotive systems, consumer devices, and industrial automation. Our Wireless Charger PCB solutions represent a specialized segment within our comprehensive power electronics manufacturing capabilities.

Wireless Charging Technology Landscape

Consumer Electronics Charging:

- Smartphone Charging Pads: 5W to 15W Qi-standard designs with foreign object detection

- Fast Wireless Chargers: 20W to 50W high-power systems with active cooling

- Portable Power Banks: Compact designs integrating wireless output and wired input

- Multi-Device Stations: Simultaneous charging for phones, watches, and earbuds

Automotive and Transportation:

- In-Vehicle Charging Systems: Dashboard-integrated pads meeting automotive EMC standards

- Electric Vehicle Charging: High-power wireless systems for stationary and dynamic charging

- Public Charging Infrastructure: Weather-resistant designs for outdoor installation

- Fleet Management Systems: Commercial vehicle charging with monitoring capabilities

Industrial and Medical Applications:

- Medical Device Charging: Biocompatible and sterile operation requirements

- IoT Sensor Networks: Low-power charging for remote monitoring devices

- Robotics and Automation: Maintenance-free charging for autonomous systems

- Harsh Environment Solutions: Industrial-grade reliability for manufacturing facilities

Smart Home and Office:

- Furniture-Integrated Charging: Invisible charging built into desks and tables

- Smart Home Hubs: Central charging stations with device management

- Conference Room Solutions: Professional presentation and meeting room charging

- Hospitality Applications: Hotel and restaurant wireless charging amenities

Advanced Power Electronics Manufacturing

Our Wireless Charger PCB manufacturing leverages specialized power electronics expertise:

High-Power Design Capabilities

Fast wireless charging systems require sophisticated power management using multilayer PCB designs to handle high-current switching circuits and electromagnetic field generation. Advanced thermal management ensures reliable operation during extended charging sessions.

Precision Assembly Services

SMT assembly lines handle power semiconductors, control ICs, and precision resonant components. Our turnkey assembly services include coil winding, magnetic shielding installation, and comprehensive electrical testing.

Material Selection Expertise

Different Wireless Charger PCB applications demand specific material properties. Consumer chargers typically utilize FR4 PCB materials, while automotive applications may require high-Tg PCB materials for enhanced thermal performance and reliability.

Quality and Certification Support

- Qi Wireless Power Consortium certification testing

- FCC, CE, and international EMC compliance validation

- Automotive AEC-Q100 qualification for vehicle applications

- Medical device regulatory support for healthcare applications

Thermal Management and Efficiency Optimization

Efficient heat dissipation directly impacts Wireless Charger PCB performance, charging speed, and user safety.

Advanced Thermal Solutions: High-power wireless chargers generate significant heat during operation. High thermal PCB materials and copper pour optimization distribute heat effectively while maintaining compact form factors essential for consumer acceptance.

Power Conversion Efficiency: Modern Wireless Charger PCBs achieve over 85% efficiency through optimized resonant circuits, synchronous rectification, and adaptive power control. Intelligent algorithms adjust transmission power based on device requirements and thermal conditions.

Electromagnetic Field Management: Precise coil design and magnetic shielding minimize electromagnetic interference while maximizing power transfer efficiency. Heavy copper PCB construction handles high currents in power transmission circuits.

Safety and Protection Systems: Comprehensive protection includes overvoltage, overcurrent, and overheat detection. Foreign object detection prevents heating of metallic objects while sophisticated algorithms ensure safe operation with various device types and orientations.

Next-Generation Charging Innovation

The wireless charging industry continues advancing with breakthrough technologies and expanding applications:

Ultra-Fast Charging Development:

- 100W+ wireless charging systems for laptops and tablets

- Gallium nitride (GaN) semiconductor integration for compact high-power designs

- Dynamic efficiency optimization based on real-time thermal monitoring

- Advanced resonant topologies minimizing electromagnetic emissions

Smart Charging Integration: Modern Wireless Charger PCBs incorporate WiFi connectivity for remote monitoring, usage analytics, and firmware updates. HDI PCB technology enables integration of wireless communication alongside power electronics in space-constrained designs.

Flexible Form Factor Solutions: Flex PCB technology enables wireless charging integration into curved surfaces, wearable devices, and automotive interior panels. These flexible solutions maintain electrical performance while conforming to complex mechanical requirements.

Long-Range and Multi-Device Charging: Emerging technologies enable charging at greater distances and simultaneous multi-device operation. Advanced beamforming and spatial multiplexing require sophisticated RF design and precise electromagnetic field control.

Why HILPCB Excels in Power Electronics Manufacturing

Wireless Charger PCBs represent our commitment to advanced power electronics manufacturing serving diverse industries worldwide. Our comprehensive capabilities extend far beyond wireless charging to include motor drives, power supplies, renewable energy systems, and industrial automation equipment.

Our Proven Advantages:

- Power Electronics Expertise: 15+ years specializing in high-power, high-frequency circuit design and manufacturing

- Scalable Production: From 10-piece engineering samples to millions of units for consumer electronics

- Technical Innovation: Advanced materials, thermal management, and electromagnetic design capabilities

- Global Compliance: Full regulatory support for international markets and industry standards

- Supply Chain Excellence: Reliable component sourcing and logistics for uninterrupted production

Whether you're developing Wireless Charger PCBs, motor control systems, power supplies, or any power electronics application, our engineering team and manufacturing infrastructure deliver the precision and reliability your products demand.

Frequently Asked Questions

Q: What power levels can you support in Wireless Charger PCB designs?

A: We manufacture Wireless Charger PCBs from 5W smartphone chargers to 100W+ laptop charging systems. Our capabilities include Qi-standard consumer devices, fast-charging implementations, and high-power automotive applications with appropriate thermal management and safety systems.

Q: How do you ensure electromagnetic compatibility in wireless charging designs?

A: Our Wireless Charger PCB designs incorporate proper shielding, optimized layout techniques, and comprehensive EMC testing. We follow international standards including FCC Part 15, CE marking requirements, and automotive EMC standards for vehicle applications.

Q: Can you handle both consumer and automotive Wireless Charger PCB requirements?

A: Yes, we serve both markets with appropriate design and manufacturing standards. Consumer applications focus on cost optimization and compact design, while automotive requires enhanced reliability, temperature performance, and AEC-Q100 qualification.

Q: What certifications do you support for wireless charging products?

A: We provide complete certification support including Qi Wireless Power Consortium testing, FCC/CE regulatory compliance, automotive qualification standards, and medical device certifications. Our quality systems ensure products meet all relevant international standards.