The 60% form factor has become the gold standard for compact mechanical keyboards, with 60% Keyboard PCB designs offering the perfect balance between functionality and portability. Modern 60 Percent PCB layouts eliminate the function row, numpad, and navigation cluster while retaining core typing functionality through programmable layers. From standardized Compact Keyboard PCB supporting universal cases to custom Mini Keyboard PCB with unique layouts, today's GH60 PCB derivatives represent the most popular enthusiast form factor driving mechanical keyboard innovation.

We provide specialized PCB manufacturing solutions optimized for 60% layouts, integrating flexible bottom row configurations for Poker Layout PCB, advanced RGB underglow systems, and comprehensive firmware support. From entry-level 60% Keyboard PCB to premium 60 Percent PCB with wireless connectivity and hot-swap sockets, our manufacturing processes support the diverse needs of keyboard designers, group buy organizers, and established brands.

60% Keyboard PCB Structure and Layout Flexibility

A versatile 60% Keyboard PCB must accommodate multiple layout options while maintaining compatibility with standard cases and plate designs. The core architecture for 60 Percent PCB includes:

- Universal mounting points compatible with GH60 PCB standard (Poker-style cases)

- Multi-layout support for Compact Keyboard PCB including split shifts and ISO compatibility

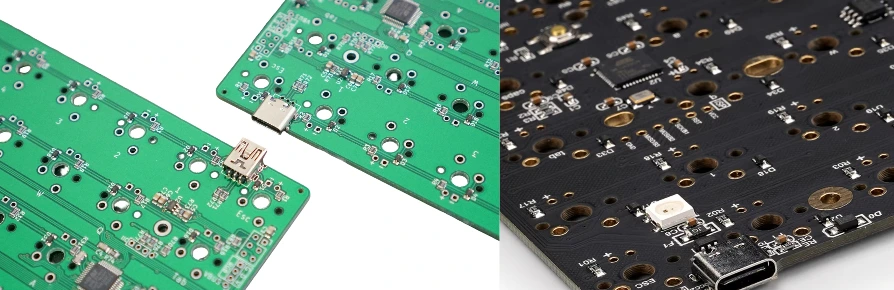

- Integrated USB-C daughterboard connections for Mini Keyboard PCB serviceability

- Per-key RGB and underglow LED support for aesthetic customization

- Flexible bottom row configurations (6.25U, 7U, split spacebar) for Poker Layout PCB

- ESD protection and fuse integration for 60% Keyboard PCB reliability

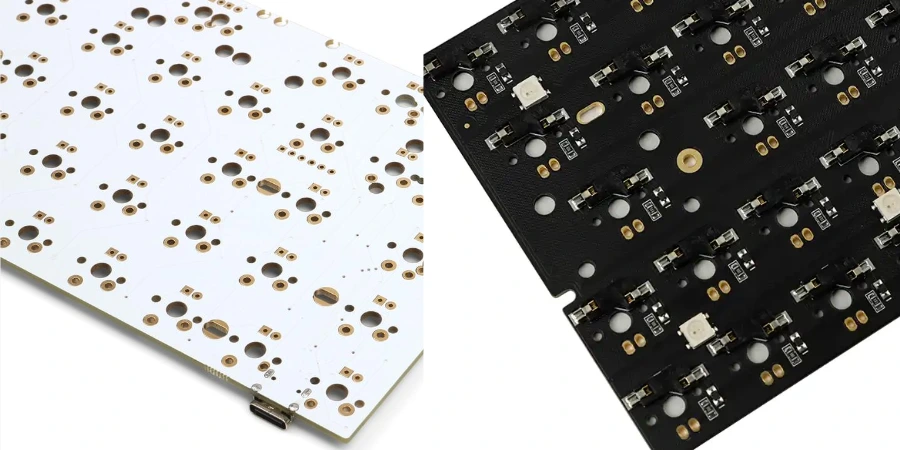

Compact Keyboard PCB designs typically employ 2-4 layer multilayer PCB structures optimized for dense routing in limited space. The challenge of Mini Keyboard PCB design lies in supporting multiple layouts while maintaining clean routing and signal integrity. GH60 PCB compatibility ensures broad ecosystem support for cases, plates, and keycap sets.

Advanced 60 Percent PCB models integrate Bluetooth modules and battery management while maintaining the compact footprint essential to the 60% form factor appeal.

Specialized Manufacturing for Compact Keyboard Electronics

Our production capabilities are specifically optimized for the space constraints of 60% Keyboard PCB and 60 Percent PCB manufacturing:

- Compact Keyboard PCB: Precision routing for standard 285mm x 95mm dimensions

- Mini Keyboard PCB: High-density component placement for maximum functionality

- GH60 PCB: Standard mounting hole compatibility for universal case support

- Poker Layout PCB: Multi-layout cutouts supporting ANSI, ISO, and exotic configurations

- 60% Keyboard PCB: HASL and ENIG finishes optimized for switch soldering

- 60 Percent PCB: Castellated holes for USB daughterboard integration

SMT assembly lines accommodate the compact nature of 60% Keyboard PCB assembly, with precise MCU placement and LED alignment. Our turnkey assembly services for Compact Keyboard PCB include firmware installation, layout testing, and compatibility verification.

Layout Options and Compatibility Standards for 60 Percent PCB Design

Designing successful 60% keyboard PCBs requires understanding community standards, layout preferences, and case compatibility requirements that have evolved within the enthusiast ecosystem.

Standard Layout Configurations

- ANSI 60% Layout Standard US layout with 61 keys, 6.25U spacebar, and 1.25U modifiers for maximum keycap compatibility.

- ISO 60% Support European layout with vertical enter key, additional key next to left shift, supporting regional requirements.

- Tsangan Layout 7U spacebar with 1.5U modifiers, popular among enthusiasts for aesthetic symmetry and vintage compatibility.

- Split Spacebar Multiple spacebar configurations (2.75U/1.25U/2.25U) enabling additional function keys and thumb cluster options.

- HHKB-Style Layout Split backspace and modified bottom row inspired by Happy Hacking Keyboard for programmer efficiency.

Mounting and Compatibility Standards

- GH60 Mounting Points Industry-standard hole positions ensuring compatibility with thousands of existing cases and plates.

- USB Cutout Positioning Centered USB placement with daughterboard support for easy cable replacement and case compatibility.

- Plate Compatibility Universal switch spacing (19.05mm) with standard stabilizer positions for 60% plate designs.

- Integrated Plate Design Optional plateless designs with 5-pin switch support for unique typing feel and reduced cost.

60% Keyboard PCB Applications and Market Segments

60% Keyboard PCB technology serves diverse user communities and use cases:

- 60% Keyboard PCB for Enthusiast Custom Builds and Group Buys

- 60 Percent PCB for Gaming and Esports Competitions

- Compact Keyboard PCB for Portable and Travel Keyboards

- Mini Keyboard PCB for Minimalist Desk Setups

- GH60 PCB for DIY Kits and Entry-Level Builds

- Poker Layout PCB for Programming and Development

- Wireless 60% PCB for Multi-Device and Mobile Setups

60 Percent PCB applications increasingly include integrated carrying cases with Compact Keyboard PCB for digital nomads and mobile professionals. Our rigid-flex PCB capabilities enable innovative Mini Keyboard PCB designs with integrated cable management.

Integrated Ecosystem Solutions for 60% Keyboard Manufacturing

Beyond core 60% Keyboard PCB manufacturing, we provide comprehensive ecosystem solutions:

Case and Plate Compatibility:

- Mounting point verification for popular case designs

- Plate clearance testing for switch and stabilizer compatibility

- USB positioning alignment for case cutouts

- Acoustic dampening integration points

Firmware Development Support:

- QMK/VIA configuration templates for 60% layouts

- Default keymap programming for common use cases

- Bootloader installation and DFU mode setup

- Layer programming documentation

Component Integration:

- Stabilizer compatibility (PCB-mount and plate-mount)

- LED underglow strip connections

- Rotary encoder support for corner positions

- Wireless module integration options

Why Choose HILPCB for 60% Keyboard PCB Manufacturing

Compact Keyboard Specialists, Backed by Full PCB Expertise

At HILPCB, we are specialists in Mechanical Keyboard PCBs, delivering reliable 60% Keyboard PCBs that balance compact layouts with stability and compatibility. But our expertise goes far beyond keyboards—we are a full-service PCB manufacturer, producing everything from consumer electronics boards to industrial control PCBs. That means you get the same engineering precision and quality assurance whether you’re building a compact keyboard or a high-performance electronic system.

Tailored Solutions for 60% Mechanical Keyboards

For compact layouts like GH60, Poker, or fully custom 60% builds, we provide optimized routing, USB-C integration, and firmware-ready support for QMK/VIA. We also handle keyboard-related companion PCBs, including LED driver boards, daughterboards for detachable cables, and wireless module PCBs. This ensures your entire keyboard ecosystem is engineered to work seamlessly together, not just the main PCB.

Scalable Production with Design Flexibility

We are ISO 9001:2015 and IPC-A-610 Class 2 certified, guaranteeing strict quality control. From small prototype runs for custom 60% layouts to mass production for gaming and commercial keyboards, we deliver PCBs that are durable, compatible, and visually striking. Options such as black-core laminates, transparent solder masks for RGB diffusion, and custom-colored finishes make your product stand out in a competitive market. With HILPCB, you gain a partner capable of supporting both specialized keyboard projects and diverse PCB applications across industries.

Frequently Asked Questions – 60% Keyboard PCB

Q1: What makes 60% Keyboard PCB the most popular compact size?

A: The 60% form factor retains all alphanumeric keys and modifiers while eliminating rarely-used keys, offers excellent portability, has widespread case/keycap compatibility, and provides enough keys for efficient typing with layers.

Q2: Can a 60 Percent PCB support multiple bottom row layouts?

A: Yes, well-designed 60% PCBs support various configurations including 6.25U spacebar (standard), 7U spacebar (Tsangan), split spacebar options, and different modifier key sizes through multiple switch positions and stabilizer mounting points.

Q3: What's the standard size for Compact Keyboard PCB in 60% format?

A: The standard PCB dimensions are approximately 285mm x 95mm, following the GH60 mounting standard with specific hole positions that ensure compatibility with most 60% cases available in the market.

Q4: How does a Mini Keyboard PCB handle arrow keys without dedicated switches?

A: 60% keyboards typically implement arrow keys through function layers (Fn + WASD or Fn + IJKL), dedicated arrow cluster in bottom right corner by sacrificing shift/modifier keys, or programmable tap/hold functionality on modifier keys.

Q5: Are GH60 PCB mounting points universally compatible?

A: GH60 mounting points have become the de facto standard for 60% keyboards, ensuring compatibility with most aftermarket cases. However, some premium or unique designs may use proprietary mounting for specific acoustic or aesthetic goals.

Q6: Can Poker Layout PCB designs support wireless connectivity?

A: Yes, modern 60% PCBs can integrate Bluetooth modules and batteries while maintaining standard dimensions. The compact layout leaves sufficient space for wireless components, though battery capacity may be limited compared to larger keyboards.