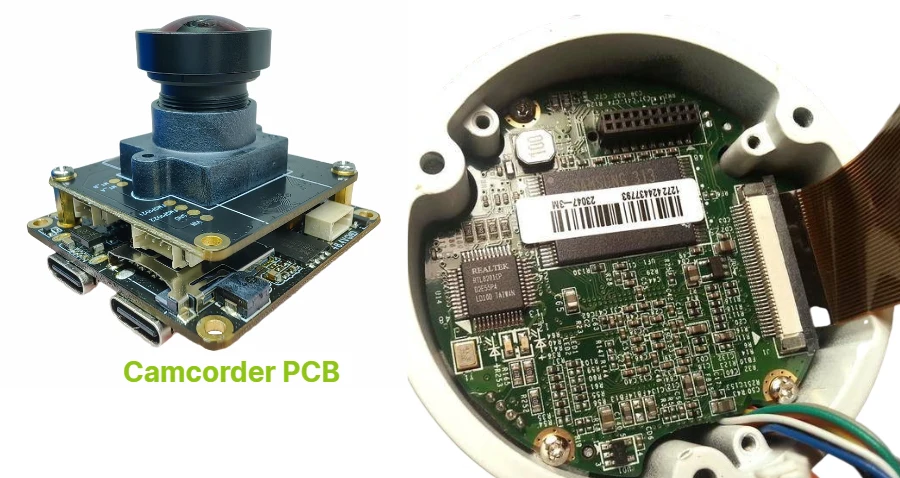

From professional broadcasting cameras to compact HD camcorders and advanced surveillance systems, every high-performance video device depends on a network of precisely engineered circuit boards. At HILPCB, we go beyond manufacturing Camcorder PCBs—we deliver complete electronic solutions including video processing boards, power supply boards, control boards, and full turnkey assembly. Our capabilities integrate high-speed image and video processing, professional audio circuits, wireless streaming modules, and robust power management into compact, reliable designs. Whether you are developing a 4K broadcasting camera, an AI-enabled security system, or a consumer HD camcorder, we provide the manufacturing precision, engineering expertise, and supply chain efficiency to bring your vision to market faster.

Camcorder PCB Architecture and High-Speed Video Processing

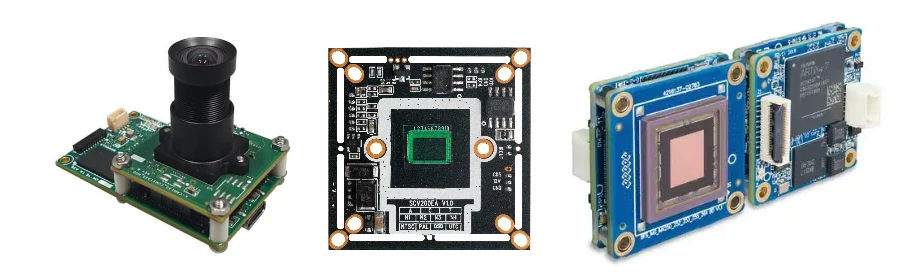

A modern Camcorder PCB must integrate multiple high-bandwidth video data paths, advanced video processors, and precision control systems within various form factors. The core architecture for Video Camera PCB applications includes:

- High-resolution CMOS and CCD image sensors with MIPI CSI-2 and LVDS video interfaces

- Multi-core ARM processors optimized for Professional Camcorder PCB real-time 4K/8K video processing

- Advanced Video Signal Processors (VSP) for HD Camera PCB noise reduction and color grading

- Broadcasting Camera PCB specific: SDI, HDMI 2.1, and USB 3.2 Gen 2 protocol support

- High-speed memory controllers for Security Camera PCB continuous recording and buffering

- WiFi 6E and Bluetooth 5.2+ modules for wireless Professional Video PCB streaming

- Precision motor controllers for optical zoom, focus, and image stabilization systems

- Multi-channel audio ADCs/DACs for professional microphone and audio recording

Professional Broadcasting Camera PCB designs typically employ 10-14 layer multilayer PCB structures to accommodate complex signal routing between video sensors, processors, and audio subsystems. The challenge of Professional Camcorder PCB design lies in maintaining exceptional signal integrity while supporting ultra-high resolution video processing and multiple high-speed data interfaces, requiring specialized high-speed PCB design techniques for gigabit video transmission.

Security Camera PCB systems increasingly integrate AI-powered video analytics and edge computing capabilities, enabling real-time object detection and intelligent monitoring in compact, network-connected form factors utilizing HDI PCB technology for maximum integration density.

Advanced Manufacturing for Video Recording Devices

Our production capabilities are specifically optimized for the complex requirements of Camcorder PCB and Video Camera PCB manufacturing:

- Professional Camcorder PCB: Ultra-low noise analog front-ends for broadcast-quality video sensor integration using FR4 PCB substrates with enhanced signal integrity properties

- HD Camera PCB: Advanced HDI technology supporting 4K/8K video processing in miniaturized form factors

- Security Camera PCB: High-reliability designs for 24/7 operation and extreme environmental conditions

- Broadcasting Camera PCB: Precision timing circuits for professional video synchronization and genlock

- Professional Video PCB: Multi-layer stackups optimized for high-bandwidth video signal integrity

- Video Camera PCB: Advanced EMI shielding for wireless coexistence and sensor protection

SMT assembly lines are configured for complex mixed-signal builds, integrating high-resolution video sensors, multi-core processors, and precision audio circuits. Our turnkey assembly services for Camcorder PCB include firmware programming, video sensor calibration, audio system integration, and comprehensive performance validation across temperature and humidity ranges.

Power Management and Video Signal Integrity

Camcorder PCB and Video Camera PCB designs require sophisticated power management to support high-performance video processing while maximizing battery life and thermal efficiency:

- Professional Camcorder PCB: Multi-rail power systems for video sensors, processors, and optical control systems

- HD Camera PCB: Ultra-efficient power delivery for extended 4K recording in compact battery configurations

- Security Camera PCB: Power-over-Ethernet Plus (PoE++) support for high-power surveillance installations

- Broadcasting Camera PCB: Professional-grade power supplies for studio and field production environments

- Professional Video PCB: Dynamic power scaling based on recording modes and streaming activity

- Advanced thermal management for high-resolution video processing and continuous operation

- High thermal PCB options for professional broadcast applications requiring extended recording sessions

Video Camera PCB designs require careful signal integrity management to prevent interference between high-speed video signals and sensitive audio circuits essential for professional video quality. High-frequency video processing operating at multi-gigahertz frequencies often requires specialized high-frequency PCB materials to ensure optimal video signal transmission and timing accuracy.

Comprehensive Video Ecosystem Solutions

Beyond core Camcorder PCB manufacturing, we provide integrated video ecosystem solutions:

Video Sensor Integration:

- High-resolution CMOS and CCD video sensor modules for Professional Camcorder PCB applications

- Specialized low-light sensors for Security Camera PCB night vision capabilities

- Ultra-compact sensor assemblies for HD Camera PCB miniaturization and action recording

- Multi-sensor arrays for Broadcasting Camera PCB multi-angle capture systems

Audio System Components:

- Professional microphone preamp modules for Professional Video PCB applications utilizing flex PCB technology for optimal audio signal routing

- Digital audio processors and codecs for Broadcasting Camera PCB integration

- Phantom power systems and XLR interface circuits for professional audio recording

- Advanced noise cancellation and audio enhancement processing modules

Connectivity and Storage:

- High-speed CFexpress and SD card interfaces for Professional Camcorder PCB recording

- USB-C and Thunderbolt connectors for HD Camera PCB data transfer and charging

- Wireless modules supporting WiFi 6E, 5G cellular, and satellite connectivity

- Cloud storage integration and real-time streaming protocol support

Advanced Video Hardware Integration

Camcorder PCB and Video Camera PCB systems require comprehensive mechanical and environmental integration:

Environmental Solutions:

- IP67/IP68 rated assemblies for outdoor Security Camera PCB installations and weather protection

- Military-grade components for defense and aerospace Broadcasting Camera PCB applications

- Shock and vibration resistance for Action Camcorder PCB extreme sports recording

- Temperature compensation for Arctic and desert Professional Video PCB operation

Professional Interface Integration:

- High-resolution LCD and OLED viewfinder controllers for Professional Camcorder PCB systems

- Touch-screen interface controls for HD Camera PCB menu navigation and settings using rigid-flex PCB solutions for optimal space utilization

- Professional control interfaces including SDI, timecode, and genlock synchronization

- Remote control and wireless monitoring system integration

Optical System Control:

- Precision servo motor drivers for Professional Camcorder PCB zoom and focus systems

- Image stabilization gyroscopes and actuators for handheld video recording

- Aperture and neutral density filter control systems for exposure management

- Auto-focus algorithms and lens calibration for optimal video sharpness

Why Choose HILPCB for Camcorder PCB Manufacturing

At HILPCB, we understand that camera and video equipment manufacturers need more than just a PCB supplier—they need a partner who can ensure performance, consistency, and fast delivery. That’s why we provide end-to-end solutions covering Camcorder PCBs, Broadcasting Camera PCBs, power boards, control boards, and interface boards, all produced with strict process control and tested for signal integrity, thermal stability, and long-term reliability. Our ISO 9001:2015 and IPC-A-610 Class 3 certifications guarantee that every board meets the highest international standards, giving you the confidence to launch products with zero compromise on quality.

Beyond manufacturing, we help our clients solve real business challenges—shortening time-to-market, reducing procurement complexity, and controlling production costs without sacrificing performance. From rapid prototyping to high-volume assembly, we manage component sourcing, SMT/THT assembly, functional testing, and full system integration under one roof. This streamlined approach not only accelerates production but also minimizes risks, ensuring your video devices—whether professional broadcast systems or consumer HD camcorders—reach the market on time and exceed customer expectations.

Frequently Asked Questions About Camcorder PCB Design and Manufacturing

Q: What are the main technical challenges in Professional Camcorder PCB design for 4K/8K video processing?

A: Professional Camcorder PCB and Video Camera PCB design involves complex challenges including ultra-high-bandwidth video data processing from multi-megapixel sensors, precision analog video signal conditioning, and thermal management for continuous 4K/8K recording. Broadcasting Camera PCB layouts require careful signal integrity management between video sensors and processors, while maintaining low noise performance essential for broadcast-quality video. Security Camera PCB designs must accommodate network protocols and real-time video compression requirements.

Q: How do you ensure reliable performance in HD Camera PCBs under varying recording conditions?

A: HD Camera PCB and rugged Camcorder PCB reliability requires advanced materials, conformal coating, and shock-resistant component mounting. Our Video Camera PCB designs utilize flexible-rigid construction, vibration-dampening techniques, and extensive environmental testing including temperature cycling, humidity exposure, and mechanical shock validation across professional video production and consumer recording applications.

Q: What specialized processes are required for Security Camera PCB manufacturing for surveillance systems?

A: Security Camera PCB and surveillance-focused Video Camera PCB manufacturing requires enhanced reliability testing, cybersecurity compliance, and 24/7 operation validation. Our manufacturing includes Camcorder PCB assembly with industrial-grade components, EMI shielding optimization, and comprehensive testing for thermal performance, power consumption, and long-term stability under continuous recording and streaming conditions.

Q: Can you manufacture both consumer and professional Camcorder PCBs including Broadcasting applications?

A: Yes. We produce Camcorder PCB solutions across all market segments from cost-effective consumer HD Camera PCB to enterprise Broadcasting Camera PCB systems. Our capabilities include Professional Camcorder PCB with broadcast-grade video processing, Action Camcorder PCB with extreme miniaturization, and specialized Professional Video PCB for cinema, medical, and scientific video applications including high-speed recording, thermal imaging, and microscopy systems.