Selecting the right high-frequency PCB manufacturer can determine the success or failure of your RF, microwave, or high-speed digital project. Unlike standard PCB fabrication, high-frequency manufacturing demands specialized equipment, materials expertise, and rigorous quality control that only select manufacturers possess. This comprehensive guide provides the essential criteria, evaluation methods, and key questions to ask when choosing a high-frequency PCB manufacturing partner for your critical applications.

1. Critical Manufacturing Capabilities for High-frequency PCBs

The foundation of any high-frequency PCB manufacturer evaluation begins with assessing their core technical capabilities. Not all PCB manufacturers can handle the stringent requirements of RF and microwave circuits, making capability verification essential before committing to a supplier.

Material Processing Expertise

HF PCB manufacturing requires expertise with specialized materials that behave differently from standard FR4. A qualified manufacturer must demonstrate:

PTFE Processing Capability: PTFE-based materials like Rogers RT/duroid require specialized lamination equipment operating at 280-320°C, compared to 185°C for standard FR4. The manufacturer should have dedicated presses with precise temperature control (±2°C) and low-pressure capability (50-150 PSI) to prevent material deformation. Surface preparation through sodium etching or plasma treatment is essential for achieving adequate copper adhesion, with peel strength exceeding 1.4 N/mm.

Hybrid Construction Experience: Modern multilayer PCB designs often combine different materials for cost optimization. The manufacturer must handle CTE mismatches between materials, prevent delamination at material interfaces, and maintain registration accuracy across dissimilar substrates. Sequential lamination capabilities enable complex hybrid stackups essential for 5G and automotive radar applications.

Impedance Control Precision

Controlled impedance is fundamental to high-frequency performance:

- Tolerance Achievement: ±5% standard, ±3% for critical applications

- Testing Capability: 100% TDR testing with documentation

- Modeling Software: Pre-production impedance prediction

- Process Control: Statistical monitoring with Cpk >1.33

The manufacturer should provide impedance test coupons on production panels and maintain comprehensive test records for traceability.

2. Quality Systems and Certifications

Quality certifications provide objective evidence of a manufacturer's commitment to excellence and process control. For high-frequency PCB manufacturing, specific certifications indicate capability levels and market focus.

Essential Certifications

ISO 9001:2015: The foundation quality management system demonstrating:

- Documented processes and procedures

- Continuous improvement methodology

- Customer satisfaction focus

- Corrective action systems

IPC Standards Compliance:

- IPC-6012 Class 3 for high-reliability applications

- IPC-A-600 for acceptability criteria

- IPC-6018 specifically for high-frequency boards

- IPC-TM-650 for test method compliance

Industry-Specific Qualifications

Different applications require specialized certifications:

Aerospace and Defense:

- AS9100D certification for aerospace quality

- ITAR registration for controlled technologies

- MIL-PRF-31032 for military applications

- NADCAP for special processes

Automotive Electronics:

- IATF 16949 for automotive quality systems

- VDA 6.3 process audits

- AEC-Q200 component qualification support

Medical Devices:

- ISO 13485 for medical device manufacturing

- FDA registration for certain applications

- Clean room capabilities for implantables

3. Technical Evaluation Criteria

Beyond certifications, technical capabilities determine whether a manufacturer can successfully produce your high-frequency PCB designs. A thorough technical evaluation should examine specific manufacturing parameters and process capabilities.

Manufacturing Process Capabilities

Dimensional Tolerances:

- Minimum trace width/spacing: 75μm (3 mil) or better

- Registration accuracy: ±50μm for critical designs

- Hole position accuracy: ±75μm

- Via diameter capability: 0.15mm minimum

Layer Count and Complexity:

- Maximum layers: 20+ for complex high-speed PCB

- Blind/buried via capability

- Sequential lamination for HDI

- Back-drilling for stub removal

Special Processes:

- Edge plating for shielding

- Cavity routing for embedded components

- Heavy copper (4-6 oz) for power applications

- Selective surface finishes

Testing and Inspection Equipment

Comprehensive testing ensures product quality:

Electrical Testing:

- Flying probe for prototype verification

- Fixture-based testing for production

- TDR systems with <35ps rise time

- Network analyzers to 40 GHz minimum

Inspection Systems:

- AOI for pattern inspection

- X-ray for via and BGA inspection

- Cross-section analysis capability

- 3D measurement systems

Environmental Testing:

- Thermal cycling chambers

- HAST for accelerated testing

- Salt spray for corrosion resistance

- Vibration and shock testing

4. Material Sourcing and Inventory Management

Access to high-frequency materials significantly impacts lead times and pricing. Evaluate the manufacturer's material sourcing strategy and inventory management practices.

Material Availability

A well-stocked manufacturer maintains:

Standard High-frequency Materials:

- Rogers RO4000 series in common thicknesses

- Rogers RT/duroid for extreme performance

- Taconic, Arlon, and Isola alternatives

- Various copper weights and surface treatments

Supply Chain Management:

- Direct relationships with material suppliers

- Buffer stock for common materials

- Lot traceability and certification

- Alternative sourcing options

Custom Material Support:

- Ability to procure specialized materials

- Minimum order quantity flexibility

- Material storage conditions (temperature/humidity controlled)

- Shelf life management systems

Cost Optimization Strategies

The manufacturer should offer:

- Material utilization optimization

- Panel size flexibility for yield improvement

- Hybrid stackup recommendations

- Volume pricing agreements

- Consignment inventory programs

5. Production Capacity and Lead Times

Understanding a manufacturer's production capacity ensures they can meet your volume requirements and delivery schedules. Evaluate both current capacity and scalability for future needs.

Capacity Assessment

Production Volume Capability:

- Prototype: 1-10 pieces with quick turnaround

- Small batch: 10-100 pieces for pilot production

- Medium volume: 100-1,000 pieces monthly

- High volume: 1,000+ pieces with consistent quality

Lead Time Performance:

- Standard prototype: 5-7 working days

- Quick-turn service: 24-72 hours available

- Production orders: 2-3 weeks typical

- Expedite options for urgent needs

Scalability Considerations

Evaluate the manufacturer's ability to grow with your needs:

- Equipment capacity and utilization rates

- Workforce scalability and training programs

- Investment in new technology

- Multiple facility locations for risk mitigation

- Disaster recovery and business continuity plans

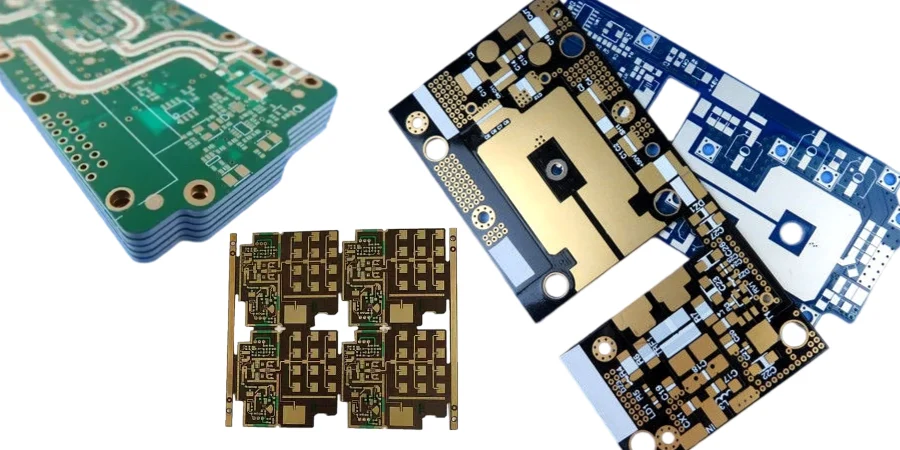

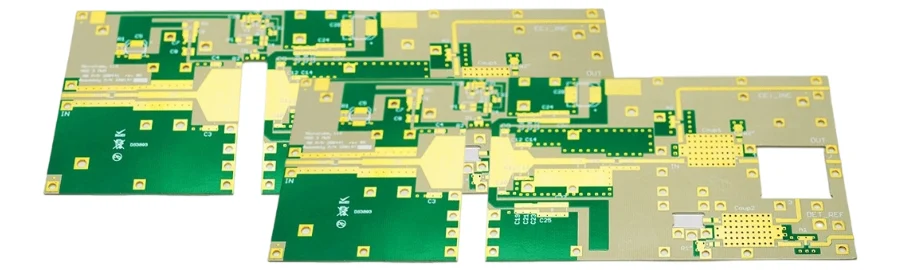

6. Why Choose HILPCB as Your High-frequency PCB Manufacturer

HILPCB exemplifies the characteristics of an ideal high-frequency PCB manufacturing partner:

- Proven Expertise: 15+ years manufacturing RF and microwave PCBs

- Advanced Equipment: State-of-the-art production lines with precise control

- Material Inventory: Comprehensive stock of all major HF materials

- Quality Systems: ISO 9001, IPC Class 3, AS9100D certified

- Technical Support: RF engineers for design consultation

- Global Reach: Serving customers in 50+ countries

- Quick Response: 24-hour quotation, dedicated project managers

Our manufacturing capabilities span from prototype to volume production, supporting applications from DC to 100 GHz with consistent quality and reliability.

7. Frequently Asked Questions (FAQ)

Q1: What questions should I ask potential HF PCB manufacturers?

A: Key questions include: What HF materials do you stock? What impedance tolerance can you guarantee? Do you have TDR testing capability? Can you provide cross-sections and test reports? What's your experience with my application area? Can you handle my volume requirements?

Q2: How do I verify a manufacturer's claimed capabilities?

A: Request facility tours (virtual or in-person), ask for sample boards and test reports, review customer references in similar applications, verify certifications through issuing bodies, and start with a prototype order before committing to volume production.

Q3: Should I choose a local or overseas HF PCB manufacturer?

A: Consider communication ease and time zones, intellectual property protection, shipping costs and lead times, quality standards and certifications, total cost including duties and logistics, and technical support availability. Many successful companies use a hybrid approach.

Q4: What red flags should I watch for when evaluating manufacturers?

A: Warning signs include: reluctance to share capabilities or certifications, no experience with your specific materials, unusually low prices compared to competitors, poor communication or slow responses, limited testing equipment, and no quality system documentation.

Q5: How important is industry-specific experience?

A: Very important. Manufacturers experienced in your industry understand specific requirements, compliance needs, and common challenges. They can provide valuable DFM feedback and often have established processes for similar applications.

Q6: What's the typical price difference between manufacturers?

A: Pricing can vary 30-50% between manufacturers for the same specifications. However, lowest price often means compromises in quality, service, or delivery. Focus on total value including quality, support, and reliability rather than unit price alone.

Ready to Partner with a Proven High-frequency PCB Manufacturer?

HILPCB combines technical excellence with responsive service to deliver high-frequency PCBs that meet your exact specifications. Contact us today for a comprehensive evaluation of your requirements.