The International Space Station's communication array began experiencing intermittent signal degradation during its fifteenth year of operation. Ground control teams noticed subtle changes in telemetry quality that could threaten the mission's ability to maintain reliable Earth communication. Investigation revealed that thermal cycling in the extreme space environment had caused impedance drift in critical RF circuits, pushing specifications beyond acceptable limits.

This scenario exemplifies why controlled impedance PCB manufacturing extends far beyond initial specification compliance. For applications where failure isn't an option—aerospace systems, life-support medical devices, and critical telecommunications infrastructure—controlled impedance means delivering PCBs that maintain electrical characteristics within tight tolerances throughout their entire operational lifetime.

At Highleap PCB Factory (HILPCB), we understand that true controlled impedance manufacturing requires systematic approaches to process control, material qualification, and comprehensive validation that address every factor influencing long-term electrical stability and reliability.

Advanced Manufacturing Process Control

Controlled impedance manufacturing demands comprehensive process control systems that monitor, adjust, and validate every parameter affecting electrical performance throughout the entire production sequence.

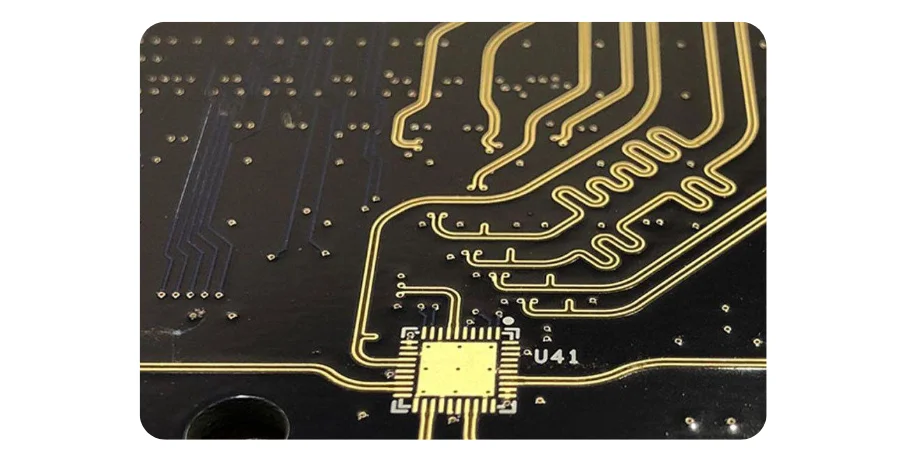

Real-Time Parameter Monitoring: Our manufacturing lines incorporate continuous monitoring of critical variables including copper plating thickness, etch rate uniformity, and substrate dimensional stability. Advanced sensor networks provide real-time feedback enabling immediate process adjustments before impedance variations exceed specification limits.

Material Lot Qualification: Every substrate material lot undergoes comprehensive characterization including dielectric constant measurement, loss tangent evaluation, and thermal expansion coefficient testing. Material certificates provide complete traceability linking final impedance performance to specific material properties for root cause analysis capabilities.

Environmental Control Integration: Manufacturing environment affects material properties and process chemistry through temperature and humidity variations. Controlled environment systems maintain consistent conditions while monitoring air quality and contamination levels that could impact electrical performance over time.

Statistical Process Control Implementation: Comprehensive SPC systems track all process variables with control charts and capability studies demonstrating manufacturing consistency. Real-time statistical analysis identifies trends before they affect product quality while validating process capability for demanding applications.

Aerospace and Defense Manufacturing Standards

Aerospace and defense applications represent the pinnacle of controlled impedance requirements, where performance margins are minimal and failure consequences extend far beyond financial considerations.

Space-Qualified Material Selection: Spacecraft electronics must operate reliably for decades in radiation environments while maintaining precise impedance control for communication and navigation systems. High-Tg PCB materials provide dimensional stability across temperature extremes from -180°C to +150°C encountered in space applications.

Military Communication Systems: Tactical communication equipment demands controlled impedance manufacturing maintaining performance under extreme environmental conditions including temperature shock, vibration, and electromagnetic interference. Manufacturing processes accommodate ITAR security requirements while delivering exceptional quality control meeting military specifications.

Radar System Implementation: Military and aerospace radar systems operate at microwave frequencies where impedance variations directly impact detection range and target discrimination capability. These applications typically require impedance control within ±1% across wide frequency ranges with exceptional temperature stability and long-term reliability.

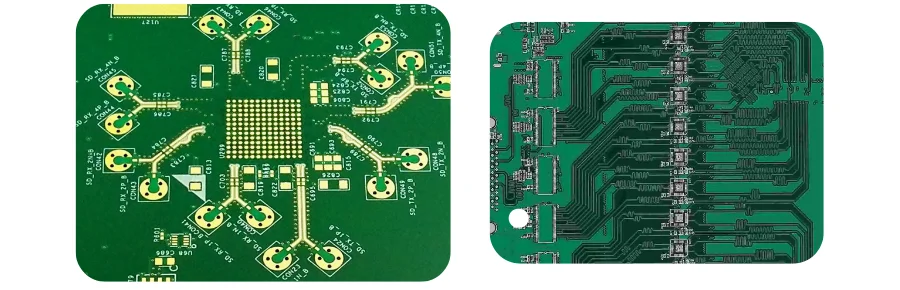

Avionics Integration: Commercial and military avionics utilize controlled impedance PCBs for flight-critical communication and navigation systems. Multilayer PCB designs integrate multiple impedance-controlled layers while meeting stringent weight constraints and shock/vibration requirements.

AS9100 Certification Compliance: Aerospace controlled impedance manufacturing requires compliance with AS9100 quality standards and extensive qualification testing. Our quality management systems demonstrate process capability through comprehensive validation and documentation meeting aerospace industry requirements.

Medical Device Manufacturing Excellence

Medical device applications require controlled impedance PCBs supporting life-critical functions while meeting rigorous regulatory requirements and biocompatibility standards.

Patient Monitoring System Design: Critical care monitors and life support equipment utilize controlled impedance PCBs for high-speed data acquisition and signal processing directly impacting patient safety. HDI PCB technology enables miniaturization necessary for portable monitoring equipment while maintaining electrical performance standards.

Surgical Equipment Control Systems: Operating room equipment demands controlled impedance manufacturing ensuring reliable operation during critical procedures. PCB designs must maintain impedance control while accommodating biocompatible materials and sterilization processes including autoclave and chemical disinfection cycles.

Implantable Device Electronics: Pacemakers, defibrillators, and neural stimulators require controlled impedance PCBs with exceptional long-term reliability in biological environments. Manufacturing processes meet ISO 13485 medical device quality standards while accommodating biocompatible materials and hermetic sealing requirements.

Diagnostic Imaging Systems: MRI, CT, and ultrasound systems utilize controlled impedance PCBs for high-resolution image acquisition and processing. These applications often operate in strong electromagnetic fields requiring specialized materials and exceptional impedance accuracy for proper system functionality.

FDA Regulatory Compliance: Medical device controlled impedance manufacturing requires compliance with FDA regulations and international medical device standards. Quality management systems demonstrate process control capability through extensive validation meeting regulatory documentation requirements.

Telecommunications Infrastructure Solutions

Telecommunications applications demand controlled impedance PCBs maintaining signal integrity across wide frequency ranges while supporting the highest data rates and most demanding reliability requirements.

5G Base Station Architecture: 5G infrastructure utilizes controlled impedance PCBs for both digital processing and RF sections, with frequency ranges extending from DC to millimeter-wave frequencies. These applications require exceptional impedance accuracy with low-loss materials and precise manufacturing tolerances for outdoor installations.

Fiber Optic Transceiver Design: High-speed optical transceivers require controlled impedance PCBs for electrical interfaces to optical components. Applications involving 100Gbps+ data rates demand impedance accuracy directly affecting bit error rates and system margins in demanding data center environments.

Network Switching Platforms: Large-scale switching systems utilize controlled impedance backplanes with thousands of high-speed signal connections. Rigid-flex PCB designs provide optimal solutions for complex backplane architectures while maintaining impedance control across challenging interconnect scenarios.

Submarine Cable Systems: Undersea telecommunications systems require controlled impedance PCBs with exceptional long-term reliability for applications where repair costs can exceed millions of dollars. These systems operate continuously for 25+ years in harsh marine environments with extreme reliability requirements.

Data Center and Computing Infrastructure

Modern data centers rely on controlled impedance PCBs for high-performance computing applications where signal integrity directly impacts processing capability and energy efficiency.

Server Motherboard Architecture

High-performance servers utilize controlled impedance PCBs for processor interfaces, memory connections, and high-speed I/O systems. DDR5 memory implementations require precise impedance control for reliable operation at maximum data rates while supporting error correction and thermal management.

Enterprise Storage Systems

Storage platforms use controlled impedance PCBs for NVMe interfaces and high-speed storage networks. These applications demand consistent impedance control for maintaining data integrity while supporting hot-swap operations and redundant system architectures.

Network Interface Card Design

100GbE and 400GbE network interface cards require exceptional impedance control for maintaining signal integrity in high-density server environments. SerDes applications operating at 50Gbps+ per lane demand manufacturing precision maintaining performance across temperature variations and aging effects.

Supercomputing Applications

High-performance computing clusters utilize controlled impedance PCBs for inter-processor communication and memory interfaces supporting parallel processing workloads. These systems require impedance consistency across thousands of high-speed connections operating synchronously.

Testing and Validation Excellence

Comprehensive testing protocols validate controlled impedance performance across all manufacturing variables and environmental conditions throughout product lifecycles.

Multi-Method Electrical Characterization: Our testing combines time domain reflectometry, network analyzer measurements, and environmental stress testing to validate impedance performance across frequency, temperature, and aging conditions. Test methods trace to national standards ensuring measurement accuracy and repeatability.

Accelerated Life Testing: Long-term impedance stability validation uses accelerated aging studies simulating years of operation under stress conditions. These studies identify potential failure modes and validate design margins for applications requiring multi-decade operational lifetimes.

Statistical Quality Control: Production testing follows comprehensive statistical sampling plans balancing testing costs with quality assurance requirements. Control charts track long-term trends while capability studies demonstrate manufacturing process consistency meeting customer requirements.

Complete Traceability Documentation: Comprehensive documentation tracks impedance measurements, material certifications, and process parameters for every production lot. Database systems enable rapid root cause analysis and provide customers with quality documentation supporting their validation requirements.

Environmental Qualification Testing: Controlled impedance PCBs undergo comprehensive environmental testing including temperature cycling, humidity exposure, vibration testing, and thermal shock qualification. Test protocols match application-specific environmental requirements ensuring reliable operation throughout product lifecycles.

Our SMT assembly capabilities integrate with controlled impedance manufacturing providing complete system solutions, while flex PCB technology extends controlled impedance to dynamic applications requiring mechanical flexibility.

Frequently Asked Questions

Q: What industries require controlled impedance PCB manufacturing? We serve aerospace, defense, medical devices, telecommunications, automotive, and high-performance computing applications where impedance accuracy directly affects system performance and reliability.

Q: What quality certifications do you maintain for controlled impedance manufacturing? We maintain AS9100 for aerospace applications, ISO 13485 for medical devices, and ITAR registration for defense applications, ensuring compliance with industry-specific quality requirements.

Q: How do you ensure long-term impedance stability? Through comprehensive material selection, environmental stress testing, and accelerated aging studies that validate impedance performance across your product's operational lifetime under specified environmental conditions.

Q: Can you provide custom impedance values for specialized applications? Yes, we manufacture custom impedance values based on your specific requirements, with complete characterization and validation testing to ensure performance meets your application needs.

Q: What documentation do you provide with controlled impedance PCBs? Complete test reports including impedance measurements, material certifications, process traveler data, and impedance measurement certificates with full traceability to national measurement standards.

Q: How do you handle design reviews for controlled impedance projects? Our engineering team conducts comprehensive design for manufacturing reviews, stackup optimization, and impedance modeling to ensure your design meets all requirements before manufacturing begins.