The mechanical keyboard enthusiast community has driven innovation in Custom Mechanical Keyboard PCB design, demanding unprecedented customization, build quality, and feature integration. Modern Keyboard PCB Design must accommodate diverse switch types, complex RGB lighting matrices, and sophisticated firmware capabilities while maintaining reliable performance for millions of keystrokes. From boutique Custom Keyboard PCB supporting exotic layouts to mass-production Gaming Keyboard PCB with advanced features, today's Mechanical Keyboard Circuit Board represents the perfect blend of electrical engineering and user experience design.

We provide specialized PCB manufacturing solutions tailored for mechanical keyboard applications, integrating hot-swap socket technology for Programmable Keyboard PCB, per-key RGB implementations, and QMK Keyboard PCB firmware compatibility. From prototype Enthusiast Keyboard PCB to high-volume Custom Mechanical Keyboard PCB production, our manufacturing processes support the quality demands of keyboard designers, boutique brands, and major gaming peripheral manufacturers.

Custom Mechanical Keyboard PCB Structure and Advanced Design

A typical Custom Mechanical Keyboard PCB must integrate sophisticated functionality while maintaining mechanical stability and electrical reliability across millions of actuations. The core architecture for Mechanical Keyboard Circuit Board includes:

- Multi-layer routing for Custom Keyboard PCB switch matrix and LED control

- USB-C connectivity with ESD protection for Programmable Keyboard PCB

- Dedicated MCU placement for QMK Keyboard PCB firmware support

- Per-key RGB LED pads and controller integration for RGB Keyboard PCB

- Hot-swap socket footprints compatible with Kailh/Mill-Max for Enthusiast Keyboard PCB

- Stabilizer mounting points and plate alignment features for Custom Mechanical Keyboard PCB

Custom Keyboard PCB designs typically employ 2-4 layer multilayer PCB structures with controlled impedance for USB high-speed data transmission. The challenge of Mechanical Keyboard Circuit Board design lies in achieving perfect switch alignment while routing complex LED matrices and maintaining signal integrity. Programmable Keyboard PCB sections enable custom firmware development and advanced macro functionality.

Advanced Gaming Keyboard PCB models integrate additional processing for N-key rollover, 1000Hz polling rates, and onboard memory for profile storage, while maintaining compatibility with standard mechanical switches.

Specialized Manufacturing for Mechanical Keyboard Electronics

Our production capabilities are specifically optimized for the unique requirements of Custom Mechanical Keyboard PCB and Keyboard PCB Design manufacturing:

- Custom Keyboard PCB: Precision CNC routing for exact switch cutout positioning

- Mechanical Keyboard Circuit Board: 1.6mm standard thickness with optional 1.2mm for low-profile builds

- Programmable Keyboard PCB: HASL/ENIG surface finishes for reliable hot-swap socket soldering

- QMK Keyboard PCB: USB-C connector assembly with reinforced mounting

- RGB Keyboard PCB: Precise LED pad placement for per-key backlighting alignment

- Enthusiast Keyboard PCB: Support for exotic layouts including split, ortholinear, and ergonomic designs

SMT assembly lines utilize specialized equipment for Custom Mechanical Keyboard PCB assembly, including precision diode placement and controller IC mounting. Our turnkey assembly services for Gaming Keyboard PCB include firmware flashing, switch testing, and RGB verification.

Layout Flexibility and Firmware Integration for Custom Keyboard PCB Design

Designing PCBs for custom mechanical keyboards requires careful consideration of layout options, firmware compatibility, and user customization requirements. Effective design strategies ensure maximum flexibility while maintaining build quality and reliability.

Layout Support by Keyboard Type

- Standard ANSI/ISO Layouts Universal compatibility with common keycap sets and standard stabilizer placement for mainstream adoption.

- Exotic Layout Support Accommodates split spacebar, stepped caps lock, and multiple bottom row configurations for enthusiast preferences.

- Ortholinear Design Grid-based switch placement with uniform 1U spacing for ergonomic typing and programming efficiency.

- Split Keyboard Architecture TRRS/USB-C interconnects between halves with I2C communication for ergonomic positioning.

- Compact Form Factors 40%, 60%, 65% layouts with function layer programming for space-conscious users.

Firmware and Programming Features

- QMK/VIA Compatibility Native support for open-source firmware with GUI configuration tools for end-user customization.

- Onboard Memory EEPROM/Flash storage for profiles, macros, and lighting patterns without software dependency.

- RGB Matrix Control Dedicated RGB controllers supporting complex animations and per-key color customization.

- Wireless Integration Bluetooth 5.0+ modules with battery management for cable-free operation and multi-device pairing.

Custom Mechanical Keyboard PCB Applications and Market Segments

Custom Mechanical Keyboard PCB technology serves diverse user communities and market segments:

- Custom Mechanical Keyboard PCB for Boutique and Small-Batch Production

- Enthusiast Keyboard PCB for Group Buys and Limited Editions

- Gaming Keyboard PCB for Esports and Professional Gaming

- Programmable Keyboard PCB for Software Development and Productivity

- QMK Keyboard PCB for Open-Source Community Projects

- RGB Keyboard PCB for Aesthetic and Lighting Enthusiasts

- Ergonomic Keyboard PCB for Health-Conscious and RSI Prevention

Mechanical Keyboard Circuit Board applications increasingly include wireless connectivity with Custom Keyboard PCB for portable and multi-device setups. Our rigid-flex PCB capabilities enable innovative Keyboard PCB Design for foldable and compact travel keyboards.

Integrated Ecosystem Solutions for Keyboard Manufacturing

Beyond core Custom Mechanical Keyboard PCB manufacturing, we provide comprehensive ecosystem solutions:

Component Sourcing:

- Mechanical switch procurement (Cherry, Gateron, Kailh, etc.)

- Hot-swap socket supply and compatibility verification

- USB-C connectors with proper mounting reinforcement

- RGB LED sourcing with binning for color consistency

Testing and Quality Control:

- Switch actuation testing across all positions

- LED functionality and color accuracy verification

- USB communication and firmware validation

- Key rollover and anti-ghosting testing

Customization Services:

- Silkscreen artwork and branding application

- Custom solder mask colors for aesthetic matching

- Plate and case compatibility verification

- Documentation and assembly guide creation

Why Choose HILPCB for Custom Mechanical Keyboard PCB Manufacturing

When customers choose a mechanical keyboard, they care about more than just functionality — they want reliability, unique aesthetics, and premium craftsmanship. At HILPCB, we understand this demand and go beyond standard PCB manufacturing by offering customized solutions that transform your keyboards into market-ready products with real impact.

- High-Quality PCBs for Premium Keyboards Every PCB we produce undergoes strict quality control, ensuring long-lasting durability, stable signal integrity, and flawless performance. From gaming keyboards with ultra-fast response times to office keyboards designed for daily heavy use, our boards are engineered for stability and precision.

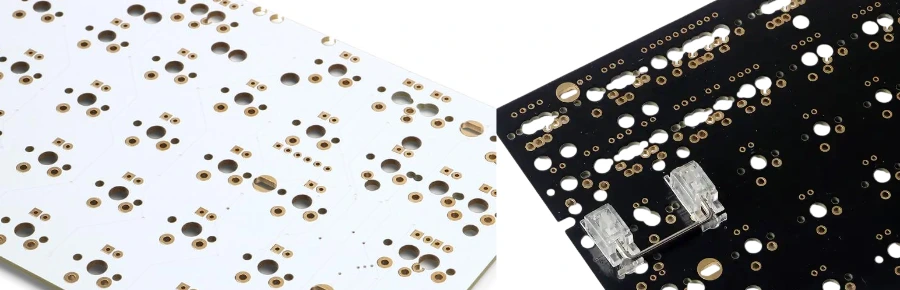

- Aesthetic and Material Innovation

We don’t just make functional boards — we help your products stand out. Our capabilities include:

- Transparent Keyboard PCBs for modern, minimalist designs.

- Colored PCBs (white, red, blue, and more) to match your brand identity.

- Black Core (Black-FR4) PCBs for premium, solid aesthetics.

- Special materials including matte, glossy, and reinforced options for added durability and visual appeal.

- Complete Customization Services Whether you need hot-swap support, RGB integration, wireless modules, or programmable layouts, our engineering team provides end-to-end support — from schematic design and layout optimization to assembly, firmware flashing, and full testing.

- One-to-One Professional Service Our dedicated project managers provide personalized consultation, ensuring your unique vision for a mechanical keyboard is transformed into a finished product that exceeds expectations. We work closely with designers, startups, and established brands alike to bring innovative ideas to life.

- From Prototype to Mass Production Whether it’s a prototype PCB for enthusiasts or high-volume runs for global brands, we guarantee on-time delivery, cost efficiency, and premium build quality at every stage of production.

At HILPCB, we don’t just supply PCBs — we help you build mechanical keyboards that people love to use and are proud to own.

👉 Ready to take your keyboard project to the next level? Contact HILPCB today for a custom PCB solution that combines engineering precision with aesthetic excellence.

Frequently Asked Questions – Custom Mechanical Keyboard PCB

Q1: What makes a good Custom Mechanical Keyboard PCB manufacturer?

A: Look for experience with precise switch cutout routing, support for multiple layouts, hot-swap socket assembly capability, and familiarity with QMK/VIA firmware requirements. Quality certifications and prototype services are essential.

Q2: How does hot-swap socket technology work in Keyboard PCB Design?

A: Hot-swap sockets (Kailh or Mill-Max) are soldered to the PCB and allow switches to be inserted without soldering. This requires reinforced pads, proper clearance, and compatible PCB thickness for reliable connection.

Q3: Why is USB-C preferred for modern Mechanical Keyboard Circuit Board?

A: USB-C offers reversible connection, higher power delivery for RGB lighting, better mechanical durability, and future-proofing. It supports USB 3.0+ speeds for faster polling rates and firmware updates.

Q4: What PCB thickness is best for Custom Keyboard PCB applications?

A: Standard 1.6mm thickness provides good rigidity and switch stability. Some enthusiasts prefer 1.2mm for flexibility or 2.0mm for premium feel. Thickness affects typing feel and acoustic properties.

Q5: How to ensure RGB lighting uniformity in RGB Keyboard PCB?

A: Use consistent LED models with binned characteristics, implement proper current limiting, design adequate power distribution traces, and consider light guides or diffusion layers for even illumination.

Q6: What's the difference between south-facing and north-facing switches on a Custom Mechanical Keyboard PCB?

A: South-facing switches have LED cutouts toward the user for better RGB visibility with shine-through keycaps. North-facing provides better compatibility with Cherry profile keycaps but may cause interference on row 3.