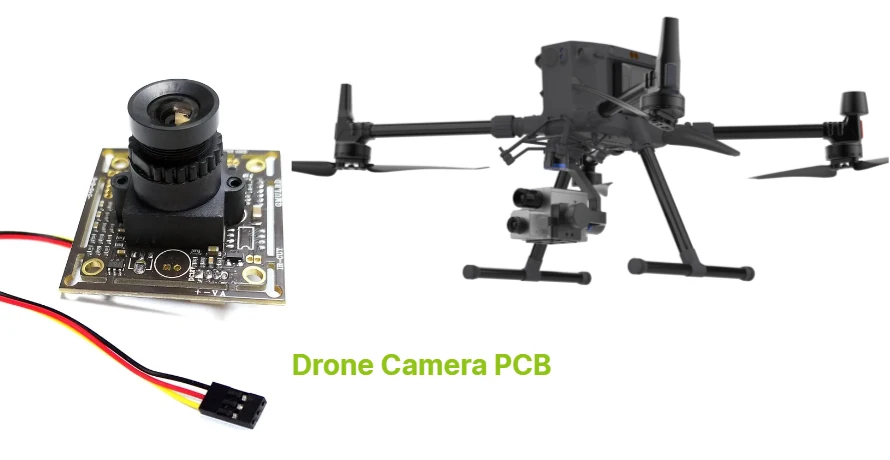

From consumer quadcopters to professional aerial survey drones and advanced surveillance UAVs, every high-performance unmanned aerial vehicle depends on a network of precisely engineered circuit boards optimized for flight. At HILPCB, we go beyond manufacturing Drone Camera PCBs—we deliver complete electronic solutions including flight control boards, gimbal stabilization boards, power distribution boards, and full turnkey assembly. Our capabilities integrate lightweight design principles, advanced image processing, wireless transmission systems, and robust power management into compact, flight-optimized designs. Whether you are developing a professional cinematography drone, an AI-enabled mapping UAV, or a consumer aerial photography platform, we provide the manufacturing precision, engineering expertise, and supply chain efficiency to bring your vision to market faster.

Drone Camera PCB Architecture and Flight-Optimized Design

A modern Drone Camera PCB must integrate high-resolution imaging systems, flight control processors, and wireless communication modules while maintaining strict weight and power constraints. The core architecture for UAV Camera PCB applications includes:

- High-resolution CMOS image sensors with MIPI CSI-2 interfaces optimized for aerial photography

- Dedicated image signal processors (ISP) for real-time video processing and stabilization

- Flight control microcontrollers for Aerial Photography PCB attitude and position control

- Quadcopter Camera PCB specific: ESC interfaces, motor control, and IMU sensor integration

- High-speed wireless modules for Commercial Drone PCB video transmission and telemetry

- GPS/GNSS receivers and barometric sensors for precision navigation

- Gimbal control systems for camera stabilization and FPV Camera PCB applications

- Ultra-efficient power management circuits for extended flight time

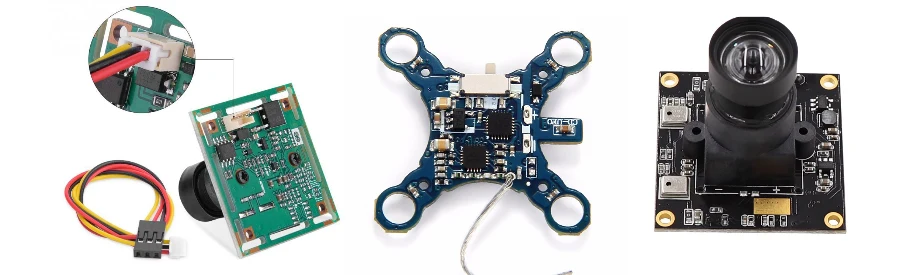

Professional Commercial Drone PCB designs typically employ 6-10 layer multilayer PCB structures to accommodate complex signal routing between flight controllers, camera systems, and communication subsystems while maintaining minimal weight. The challenge of UAV Camera PCB design lies in balancing performance requirements with strict size and weight constraints, requiring specialized high-speed PCB design techniques for high-frequency communication and video transmission.

FPV Camera PCB systems increasingly integrate AI-powered image processing and autonomous flight capabilities, enabling real-time object tracking and intelligent navigation in lightweight, compact form factors utilizing HDI PCB technology for maximum component density while minimizing overall system weight.

Advanced Manufacturing for UAV Applications

Our production capabilities are specifically optimized for the unique requirements of Drone Camera PCB and UAV Camera PCB manufacturing:

- Aerial Photography PCB: Ultra-lightweight designs using FR4 PCB substrates with optimized copper distribution for weight reduction while maintaining signal integrity

- Quadcopter Camera PCB: Advanced miniaturization techniques supporting 4K video processing in space-constrained designs

- Commercial Drone PCB: High-reliability designs for industrial applications with extended operating temperature ranges using high-Tg PCB materials for enhanced thermal stability

- FPV Camera PCB: Low-latency video transmission circuits with optimized RF performance

- UAV Camera PCB: Advanced vibration resistance and shock protection for demanding flight conditions

- Drone Camera PCB: Integrated EMI shielding for wireless coexistence and sensor protection

SMT assembly lines are configured for precision placement of miniature components, integrating high-resolution image sensors, flight control processors, and wireless communication modules. Our turnkey assembly services for Drone Camera PCB include firmware programming, sensor calibration, flight testing validation, and comprehensive environmental testing across operating temperature and vibration ranges.

Power Management and Weight Optimization

Drone Camera PCB and UAV Camera PCB designs require sophisticated power management to maximize flight time while supporting high-performance imaging and processing systems:

- Aerial Photography PCB: Multi-rail power systems optimized for battery efficiency and camera sensor power requirements

- Quadcopter Camera PCB: Ultra-efficient switching regulators for extended flight duration in consumer applications

- Commercial Drone PCB: Industrial-grade power systems supporting high-power payloads and extended mission profiles

- FPV Camera PCB: Low-power video transmission circuits optimized for racing and recreational flying

- UAV Camera PCB: Dynamic power scaling based on flight modes and imaging requirements

- Advanced thermal management for high-resolution image processing while maintaining lightweight design

- High thermal PCB options for professional applications requiring continuous operation

UAV Camera PCB designs require careful weight optimization techniques, including the use of lightweight flex PCB interconnects for gimbal systems and camera modules, reducing overall system weight while maintaining reliability. High-frequency video transmission often requires specialized high-frequency PCB materials to ensure optimal signal transmission while minimizing interference with flight control systems.

Comprehensive UAV Ecosystem Solutions

Beyond core Drone Camera PCB manufacturing, we provide integrated unmanned aerial vehicle ecosystem solutions:

Camera System Integration:

- High-resolution CMOS camera modules for Aerial Photography PCB applications with integrated image stabilization

- Specialized low-light sensors for Commercial Drone PCB surveillance and inspection operations

- Ultra-compact camera assemblies for Quadcopter Camera PCB racing and recreational applications

- Multi-camera arrays for FPV Camera PCB immersive recording and mapping systems

Flight Control Components:

- Precision IMU sensor modules for UAV Camera PCB stability and navigation utilizing rigid-flex PCB technology for optimal space utilization in flight controller assemblies

- GPS/GNSS receiver modules with integrated antennas for precise positioning

- Barometric pressure sensors and magnetometers for autonomous flight capabilities

- Advanced ESC integration for motor control and power distribution

Communication and Telemetry:

- Long-range wireless modules supporting video transmission and control telemetry

- FPV transmission systems for real-time video streaming to ground stations

- Cellular and satellite communication modules for beyond-visual-line-of-sight operations

- Emergency communication systems and automated return-to-home functionality

Why Choose HILPCB for Drone Camera PCB Manufacturing

At HILPCB, we understand that drone and UAV manufacturers need more than just a PCB supplier—they need a partner who can deliver performance, reliability, and rapid iteration capabilities. That's why we provide end-to-end solutions covering Drone Camera PCBs, flight control boards, power distribution systems, and communication modules, all produced with aerospace-grade process control and tested for flight performance, environmental durability, and regulatory compliance. Our ISO 9001:2015 and IPC-A-610 Class 3 certifications, combined with specialized aerospace manufacturing experience, guarantee that every board meets the stringent requirements of unmanned aerial systems.

Beyond manufacturing, we help our clients overcome the unique challenges of UAV development—meeting weight constraints, achieving regulatory certification, and accelerating time-to-market for innovative aerial platforms. From rapid prototyping to high-volume production, we manage component sourcing optimized for aerospace applications, precision assembly with flight-critical quality standards, comprehensive testing including vibration and thermal cycling, and full system integration support. This specialized approach not only ensures reliable flight performance but also helps navigate the complex regulatory landscape, ensuring your drone platforms—whether consumer Quadcopter Camera PCB systems or professional Commercial Drone PCB platforms—achieve certification and exceed market expectations.

Frequently Asked Questions About Drone Camera PCB Design and Manufacturing

Q: What are the main design challenges in Aerial Photography PCB for professional drone applications?

A: Aerial Photography PCB and UAV Camera PCB design involves unique challenges including strict weight constraints, vibration resistance, and thermal management in flight conditions. Drone Camera PCB layouts require careful balance between performance and weight, while maintaining signal integrity for high-resolution video transmission. Commercial Drone PCB designs must accommodate regulatory requirements, extended flight times, and professional imaging quality while meeting certification standards for commercial operations.

Q: How do you ensure reliable performance in Quadcopter Camera PCBs under flight stress conditions?

A: Quadcopter Camera PCB and ruggedized Drone Camera PCB reliability requires specialized materials, conformal coating, and shock-resistant component mounting designed for aerial applications. Our UAV Camera PCB designs utilize flexible-rigid construction, vibration-dampening techniques, and extensive flight testing including temperature cycling, humidity exposure, and mechanical stress validation across consumer and professional drone applications under actual flight conditions.

Q: What specialized processes are required for FPV Camera PCB manufacturing for racing drones?

A: FPV Camera PCB and high-performance UAV Camera PCB manufacturing requires low-latency video processing, high-frequency RF optimization, and ultra-lightweight construction. Our manufacturing includes Drone Camera PCB assembly with aerospace-grade components, advanced EMI shielding for wireless coexistence, and specialized testing for video transmission quality, power efficiency, and real-time performance under high-G flight maneuvers typical of racing applications.

Q: Can you manufacture both consumer and commercial Drone Camera PCBs including industrial applications?

A: Yes. We produce Drone Camera PCB solutions across all market segments from cost-effective consumer Quadcopter Camera PCB to enterprise Commercial Drone PCB systems. Our capabilities include Aerial Photography PCB with professional-grade imaging processing, FPV Camera PCB with ultra-low latency transmission, and specialized UAV Camera PCB for industrial applications including surveying, inspection, agriculture, and security surveillance systems with extended flight capabilities and advanced autonomous features.