The earbuds market has revolutionized personal audio with the transition from wired to True Wireless Earbuds Circuit Board designs that pack sophisticated technology into incredibly compact form factors. Central to every modern earbud is the Earbuds PCB—an ultra-miniaturized circuit board that manages Bluetooth connectivity, audio processing, battery management, and touch controls within spaces measuring just a few millimeters. From TWS Earbuds PCB requiring extreme miniaturization to Sports Earbuds PCB with integrated health sensors, today's Wireless Earbuds PCB designs represent the pinnacle of electronic miniaturization and power efficiency.

We provide specialized PCB fabrication and assembly solutions tailored for the unique challenges of Earbuds manufacturing, integrating advanced Bluetooth Earbuds PCB technologies, ultra-low power circuits, and Miniature Earbuds PCB designs. From budget In-Ear Earbuds PCB to premium ANC Earbuds PCB with active noise cancellation, our manufacturing processes support the extreme miniaturization and reliability demands of global audio brands and emerging TWS manufacturers.

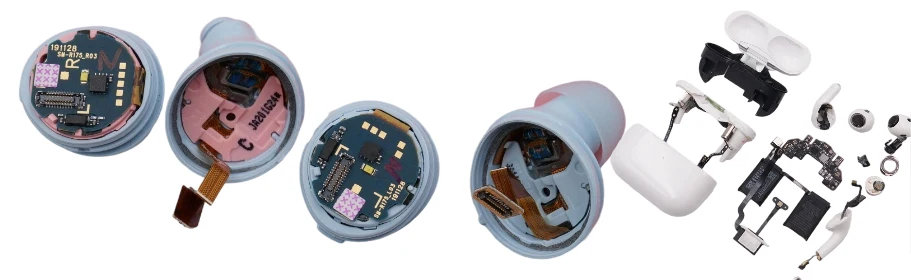

Earbuds PCB Structure and Ultra-Miniaturized Design

A typical Earbuds PCB must integrate complete wireless audio functionality within extremely constrained dimensions, typically under 15mm x 8mm for TWS Earbuds PCB applications. The core architecture for Wireless Earbuds PCB includes:

- Ultra-compact Bluetooth 5.0+ SoC with integrated antenna for True Wireless Earbuds Circuit Board

- Miniaturized audio DACs and amplifiers optimized for In-Ear Earbuds PCB drivers

- Battery management ICs with wireless and contact charging for TWS Earbuds PCB

- ANC Earbuds PCB specific: MEMS microphones and DSP for noise cancellation

- Capacitive touch sensors for tap and gesture controls

- Sports Earbuds PCB enhancements: PPG sensors, accelerometers, and sweat-resistant coatings

Miniature Earbuds PCB designs typically employ 4-6 layer multilayer PCB structures with layer thicknesses optimized for ultra-compact assembly. The challenge of Bluetooth Earbuds PCB design lies in achieving reliable RF performance while maintaining minimal interference with sensitive analog audio circuits. Rigid-flex PCB for Earbuds sections enable stem connections and antenna optimization in True Wireless Earbuds Circuit Board applications where every millimeter counts.

Advanced Gaming Earbuds PCB models integrate additional processing for low-latency audio and spatial sound processing, while maintaining the ultra-compact form factors essential for comfortable wear.

Specialized Manufacturing for Ultra-Compact Audio Devices

Our production capabilities are specifically optimized for the extreme miniaturization requirements of Earbuds PCB and TWS Earbuds PCB manufacturing:

- Miniature Earbuds PCB: Substrates as thin as 0.4mm with high-frequency materials for optimal wireless performance

- Wireless Earbuds PCB: Advanced HDI technology with microvias and buried vias for maximum density

- True Wireless Earbuds Circuit Board: Precision SMT assembly supporting 008004 components and ultra-fine pitch BGAs

- Bluetooth Earbuds PCB: Controlled impedance routing with ±3% tolerance for critical RF signals

- Rigid-flex PCB for Earbuds: Specialized flex-rigid combinations for antenna integration and mechanical flexibility

- ANC Earbuds PCB: Ultra-precise analog circuit assembly for microphone arrays and feedback control

SMT assembly lines utilize specialized equipment for In-Ear Earbuds PCB assembly, including microscopic component placement and precision solder paste printing. Our turnkey assembly services for Sports Earbuds PCB include environmental sealing, sensor calibration, and comprehensive audio testing.

Power Management and Battery Optimization for TWS Applications

TWS Earbuds PCB and Wireless Earbuds PCB designs face unique power management challenges requiring sophisticated battery optimization:

- True Wireless Earbuds Circuit Board: Ultra-low quiescent current designs for extended standby time

- Bluetooth Earbuds PCB: Dynamic power scaling based on audio processing requirements

- ANC Earbuds PCB: Efficient power distribution between audio processing and noise cancellation circuits

- Sports Earbuds PCB: Power optimization for continuous health monitoring and GPS connectivity

- Gaming Earbuds PCB: Low-latency processing with minimal power impact

- Advanced charging algorithms for Miniature Earbuds PCB with both wireless and contact charging

- High thermal PCB options for fast-charging applications in compact charging cases

In-Ear Earbuds PCB designs require careful thermal management to prevent user discomfort during extended use, while Rigid-flex PCB for Earbuds enables optimal battery placement and heat dissipation.

Earbuds PCB Applications and Market Segments

Earbuds PCB technology serves diverse market segments, each with specific technical requirements:

- TWS Earbuds PCB for Premium Consumer True Wireless Models

- Wireless Earbuds PCB for Fitness and Sports Applications with Health Monitoring

- Bluetooth Earbuds PCB for Budget-Conscious Consumer Markets

- ANC Earbuds PCB for Professional and Travel-Focused Noise Cancellation

- Gaming Earbuds PCB with Ultra-Low Latency and Spatial Audio Processing

- In-Ear Earbuds PCB for Hearing Aids and Assistive Listening Devices

- Sports Earbuds PCB with Integrated Biometric Sensors and Waterproofing

True Wireless Earbuds Circuit Board applications increasingly include charging case electronics with Miniature Earbuds PCB for case-to-earbud communication and power management. Our rigid-flex PCB capabilities enable optimal Rigid-flex PCB for Earbuds designs that accommodate complex antenna patterns and mechanical constraints.

Integrated Ecosystem Solutions for Earbuds Manufacturing

Beyond core Earbuds PCB manufacturing, we provide comprehensive ecosystem solutions:

Charging Case Electronics:

- TWS Earbuds PCB compatible charging case circuits with wireless charging

- Battery management systems for multi-device charging

- LED status indicators and magnetic sensor integration

- USB-C and wireless charging receiver circuits

Advanced Component Integration:

- Custom antenna solutions for Wireless Earbuds PCB applications

- MEMS microphone arrays for ANC Earbuds PCB designs

- Biometric sensors for Sports Earbuds PCB health monitoring

- Haptic feedback modules for Gaming Earbuds PCB immersive experiences

Software and Firmware Support:

- TWS pairing and synchronization algorithms

- Bluetooth Earbuds PCB audio codec optimization

- Mobile app development for True Wireless Earbuds Circuit Board control

- Machine learning integration for adaptive ANC Earbuds PCB performance

Why Choose HILPCB for Earbuds PCB Manufacturing

The Earbuds market demands exceptional miniaturization, reliability, and cost efficiency. HILPCB combines advanced manufacturing technology with deep expertise in Miniature Earbuds PCB design and TWS Earbuds PCB assembly to support brands delivering cutting-edge audio products.

We are ISO 9001:2015 and IPC-A-610 Class 3 certified, with specialized capabilities in ultra-miniaturized electronics and Wireless Earbuds PCB manufacturing. Our engineering teams provide antenna optimization, power management design, and thermal analysis specifically for True Wireless Earbuds Circuit Board applications. From prototype In-Ear Earbuds PCB to high-volume Bluetooth Earbuds PCB production, we ensure reliable delivery with focus on audio performance, battery life, and manufacturing yield optimization.

Frequently Asked Questions About Earbuds PCB Design and Manufacturing

Q: What are the main technical challenges in TWS Earbuds PCB design and ultra-miniaturization?

A: TWS Earbuds PCB and True Wireless Earbuds Circuit Board design involves extreme miniaturization challenges including antenna integration in sub-10mm spaces, battery life optimization in minimal volumes, and maintaining audio quality while preventing interference between Bluetooth signals and analog circuits. Miniature Earbuds PCB layouts require advanced HDI technology, 008004 components, and sophisticated thermal management within incredibly constrained form factors.

Q: How do you ensure reliable wireless connectivity in ultra-compact Earbuds PCB designs?

A: Wireless Earbuds PCB and Bluetooth Earbuds PCB reliability requires optimized antenna placement using Rigid-flex PCB for Earbuds technology, precise impedance control, and advanced EMI shielding. Our True Wireless Earbuds Circuit Board designs utilize antenna diversity, ground plane optimization, and comprehensive testing including wireless range validation, audio synchronization, and interference immunity across diverse environments.

Q: What specialized manufacturing processes are required for ANC Earbuds and Sports Earbuds PCBs?

A: ANC Earbuds PCB manufacturing demands precision analog circuit assembly and specialized testing for noise cancellation effectiveness. Sports Earbuds PCB requires environmental sealing, sensor calibration, and sweat-resistance validation. Our manufacturing includes In-Ear Earbuds PCB assembly with conformal coating, IP67 sealing processes, and comprehensive environmental testing for temperature, humidity, and mechanical stress resistance.

Q: Can you manufacture both budget and premium Earbuds PCBs including gaming applications?

A: Yes. We produce Earbuds PCB solutions across all market segments from cost-effective In-Ear Earbuds PCB to premium ANC Earbuds PCB with advanced noise cancellation. Our capabilities include Gaming Earbuds PCB with ultra-low latency processing, Sports Earbuds PCB with integrated health sensors, and specialized True Wireless Earbuds Circuit Board for professional audio applications including broadcast monitoring and assistive listening devices.