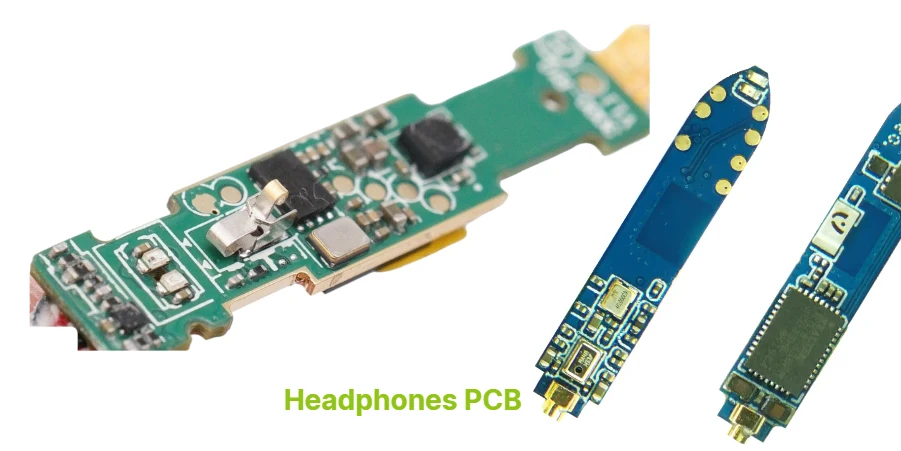

Modern headphones have evolved from simple analog transducers to sophisticated audio systems incorporating wireless connectivity, active noise cancellation, and intelligent sound processing. Central to their functionality is the Headphones PCB—a highly integrated circuit board that manages audio decoding, Bluetooth communication, battery management, and user controls. With increasing demand for compact form factors, extended battery life, and premium audio quality, modern headphone PCBs must combine high-frequency RF design with low-noise analog audio circuits.

We provide PCB fabrication and assembly solutions tailored for all headphone categories, integrating wireless modules, DSP processors, ANC circuits, and power management systems. From true wireless earbuds to premium over-ear headphones, gaming headsets, and professional studio monitors, our manufacturing processes support durable, cost-effective PCB builds for global audio brands and OEMs.

Headphones PCB Structure and Functional Blocks

A typical headphones PCB handles wireless communication, audio processing, and power management within ultra-compact footprints. The core architecture includes:

- Bluetooth 5.0+ SoC with integrated antenna matching circuits

- Digital Signal Processors (DSP) for ANC, EQ, and spatial audio

- Audio DACs and ADCs with low-noise amplifier stages

- Battery management ICs with USB-C/Lightning charging circuits

- Capacitive touch sensors, buttons, and LED control systems

Many designs employ 4–6 layer multilayer PCB structures for optimal RF performance and power distribution. High-frequency Bluetooth and Wi-Fi signals require controlled impedance routing, while sensitive analog audio paths demand careful grounding and shielding. Flexible PCB sections enable comfortable wearability in earbuds and headband connections.

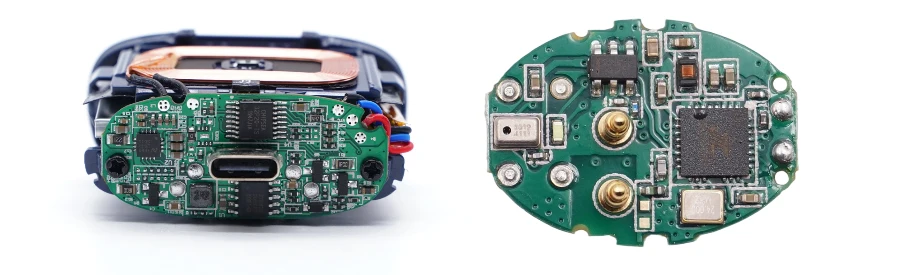

Advanced models supporting features like adaptive ANC, biometric sensors, and voice assistants integrate additional processing power through dedicated microcontrollers and sensor interface circuits.

Manufacturing Capabilities for Audio Applications

Our production lines support scalable and efficient fabrication for audio devices, including wireless earbuds, over-ear headphones, and specialized audio equipment.

- Substrates: High-frequency materials for optimal wireless performance

- Finish options: ENIG/OSP for fine-pitch BGA and antenna connections

- SMT support: Placement of 01005 components and advanced packaging

- Impedance tolerance: ±5% on RF transmission lines and differential pairs

SMT assembly lines are configured for ultra-miniaturized builds, integrating Bluetooth SoCs, MEMS microphones, and sensor arrays. We also provide turnkey assembly for brands seeking complete solutions with firmware programming, acoustic testing, and quality validation.

Our capabilities extend to gaming headsets, professional audio equipment, hearing aids, and specialized communication devices for industrial and aviation applications.

Power, Signal, and Thermal Management Considerations

High-performance headphones PCBs must optimize power consumption while maintaining excellent audio quality and reliable wireless connectivity.

- RF isolation between Bluetooth/Wi-Fi and sensitive audio circuits

- Battery optimization with adaptive power management algorithms

- EMI shielding for ANC microphones and audio signal paths

- High thermal PCB options for fast-charging and high-power amplifier applications

For premium models with advanced processing capabilities, high-speed PCB designs ensure stable performance of multi-core DSPs and machine learning accelerators.

Peripheral Integration and Use Cases

Headphones PCBs serve as the foundation for diverse audio product families, including:

- True Wireless Earbuds with Charging Cases

- Over-Ear and On-Ear Wireless Headphones

- Gaming Headsets with RGB Lighting and Microphones

- Professional Studio Monitors and DJ Headphones

- Sports and Fitness Earbuds with Health Sensors

- Hearing Aids and Assistive Listening Devices

These applications require varying antenna configurations, sensor integrations, and mechanical constraints. Our rigid-flex PCB capabilities enable optimal form factor optimization while maintaining signal integrity and durability.

Supporting Components and Ecosystem Solutions

Beyond core PCB manufacturing, we provide comprehensive component integration and system-level solutions:

Audio Components:

- Premium audio codecs and amplifier ICs

- MEMS microphones for voice and ANC applications

- Bluetooth and Wi-Fi modules with certified antenna designs

- Lithium battery cells with protection circuits

Mechanical Integration:

- Custom flex cables for driver connections

- Antenna integration and tuning services

- Charging case electronics and magnetic connectors

- Environmental sealing and sweat-resistance solutions

Software Support:

- Firmware development for Bluetooth stacks and audio processing

- Mobile application development for device control

- Over-the-air update implementation

- Acoustic tuning and certification testing

Why Partner with HILPCB

Choosing the right PCB partner is critical for success in the competitive headphones market. HILPCB combines advanced manufacturing technology, extensive audio industry experience, and comprehensive quality systems to support brands delivering premium audio products.

We are ISO 9001:2015 and IPC-A-610 Class 3 certified, with specialized experience in RF design, miniaturization, and audio electronics. Our engineering teams provide antenna optimization, thermal modeling, and acoustic design support. From prototype development to high-volume production, we ensure reliable delivery with focus on audio performance, battery life, and user experience.

Frequently Asked Questions About Headphones PCB Design and Manufacturing

Q: What are the main technical challenges in wireless headphones PCB design and layout?

A: Designing Wireless Headphones PCB and TWS Earbuds Circuit Board involves key challenges such as antenna integration in compact spaces, battery life optimization, and maintaining audio quality while minimizing interference between Bluetooth signals and sensitive analog circuits. ANC Headphones PCB designs require additional complexity for microphone array processing and feedback loop stability. The layout must accommodate RF components, DSP processors, and power management while achieving ultra-miniaturized form factors.

Q: How do you ensure reliable Bluetooth connectivity and audio performance in gaming headset PCBs?

A: Reliable Gaming Headset PCB wireless performance requires careful antenna placement, proper ground plane design, and EMI shielding between digital RGB controllers and analog audio sections. For Wireless Headphones PCB applications, we use controlled impedance routing for RF signals, optimize antenna matching networks, and implement comprehensive testing including wireless range, audio latency, and interference immunity validation.

Q: What specialized manufacturing processes are needed for TWS earbuds and ANC headphones?

A: TWS Earbuds Circuit Board manufacturing requires advanced miniaturization techniques including 01005 component placement and Rigid-flex PCB for Headphones integration. ANC Headphones PCB production demands precision analog circuit assembly and specialized testing for noise cancellation performance. Our testing includes Bluetooth certification pre-compliance, THD+N audio measurements, and ANC effectiveness validation across frequency ranges.

Q: Can you manufacture both consumer and professional-grade headphones PCBs including planar designs?

A: Yes. We produce PCBs for the complete spectrum including cost-effective TWS Earbuds Circuit Board, premium Wireless Headphones PCB, specialized Gaming Headset PCB, and high-end Planar Headphones PCB for audiophile applications. Our scalable processes support volume production for consumer brands and specialized ANC Headphones PCB builds for professional audio applications including broadcast, aviation, and medical devices.