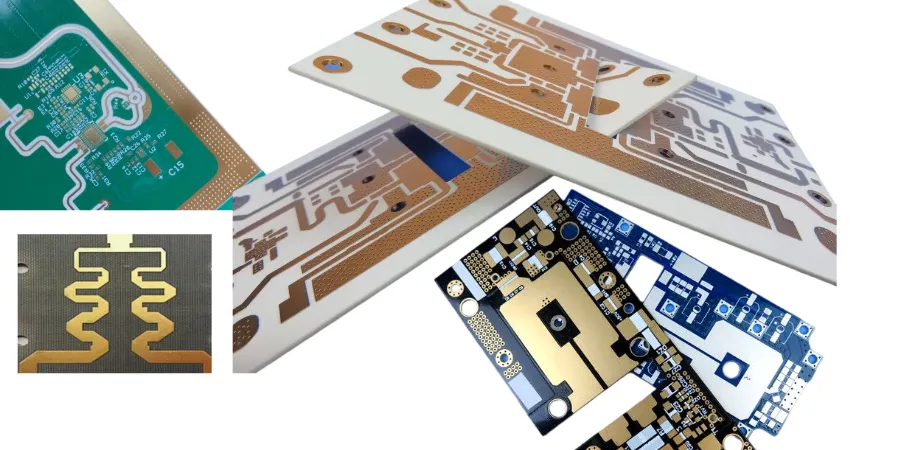

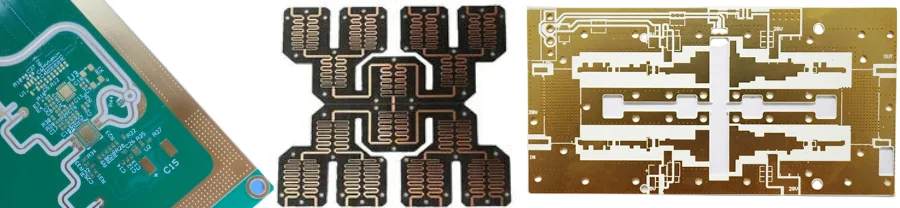

The evolution of wireless communication systems toward higher frequencies and data rates has driven remarkable advances in PCB substrate materials. Modern HF PCB applications—from 5G base stations operating at 28 GHz to automotive radar systems at 77 GHz—demand materials engineered with precise electrical properties, exceptional thermal stability, and consistent performance under extreme environmental conditions.

Selecting the optimal substrate material for RF/microwave circuits requires a deep understanding of dielectric properties, loss mechanisms, and manufacturing constraints. With material costs ranging from three to fifteen times that of standard FR4, engineers must balance electrical performance requirements against economic considerations while ensuring manufacturability and long-term reliability. This guide examines the latest high-frequency substrate technologies, selection criteria, and application-specific recommendations for professional PCB design.

Critical Electrical Properties for RF Performance

Understanding Dielectric Constant and Its Impact

Dielectric constant (Dk) fundamentally determines signal propagation velocity and characteristic impedance in transmission lines. For high-frequency applications, both the absolute value and stability of Dk across frequency, temperature, and humidity are critical design parameters.

The Relationship Between Dk and Circuit Performance:

Lower Dk values offer several advantages for RF circuits:

- Faster signal propagation (v = c/√Dk)

- Wider trace widths for given impedance (easier manufacturing)

- Reduced parasitic capacitance in component pads

- Lower radiation loss at discontinuities

However, higher Dk materials enable circuit miniaturization, crucial for phased array antennas and portable devices where size constraints dominate.

Industry-Leading Materials by Dk Range:

| Dk Range | Material Examples | Typical Applications |

|---|---|---|

| 2.0-2.5 | RT/duroid 5880, TLY-5 | Broadband, low-loss circuits |

| 3.0-3.5 | RO4003C, RO4350B | General purpose RF, 5G |

| 4.0-5.0 | TMM4, RO4835 | Miniaturized circuits |

| 6.0-10.0 | TMM10i, CER-10 | High-K applications |

Temperature coefficient of dielectric constant (TCDk) must remain below ±50 ppm/°C for stable performance across operating temperature ranges. Premium materials achieve TCDk values as low as ±12 ppm/°C.

Loss Tangent: The Key to Power Efficiency

Loss tangent (Df) represents the ratio of energy lost to energy stored per cycle, directly impacting insertion loss and power efficiency. As frequency increases, even small differences in Df significantly affect system performance.

Calculating Insertion Loss from Material Properties:

Total insertion loss = Conductor loss + Dielectric loss + Radiation loss

Dielectric loss (dB/inch) = 2.3 × f(GHz) × √Dk × Df

For a 10 GHz signal in RO4003C (Dk=3.38, Df=0.0027): Dielectric loss = 2.3 × 10 × √3.38 × 0.0027 = 0.114 dB/inch

Loss Tangent Requirements by Application:

- Digital/Power (DC-1 GHz): Df < 0.020 acceptable

- Cellular Infrastructure (1-6 GHz): Df < 0.010 required

- 5G mmWave (24-40 GHz): Df < 0.005 essential

- Satellite/Radar (>40 GHz): Df < 0.002 mandatory

Advanced Material Categories and Technologies

PTFE-Based Composites: The Gold Standard

PTFE (polytetrafluoroethylene) based materials represent the pinnacle of RF performance, offering the lowest loss tangent and most stable electrical properties available.

Woven Glass Reinforced PTFE Excellence:

Rogers RT/duroid 5880 remains the industry benchmark for demanding applications:

- Dielectric constant: 2.20 ±0.02

- Loss tangent: 0.0009 at 10 GHz

- Moisture absorption: <0.02%

- Operating temperature: -273°C to +250°C

The woven glass reinforcement provides dimensional stability while maintaining exceptional electrical properties. However, the material requires specialized processing including sodium etching for adhesion and controlled lamination parameters.

Ceramic-Filled PTFE Innovation:

Modern ceramic-filled PTFE composites offer enhanced mechanical properties and thermal conductivity:

Rogers TMM Series Advantages:

- Isotropic dielectric properties (no glass weave effect)

- Thermal conductivity up to 0.76 W/m·K

- Reduced CTE for improved reliability

- Resistance to thermoset processing temperatures

The ceramic filler loading determines final Dk value, enabling designers to select specific values from 3.27 to 12.85 while maintaining low loss characteristics.

Hydrocarbon Ceramic Laminates: Balancing Performance and Cost

The development of hydrocarbon ceramic materials revolutionized high-speed PCB manufacturing by combining good RF performance with standard processing compatibility.

Rogers RO4000 Series Success Story:

RO4003C and RO4350B have become industry standards for commercial RF applications:

Key Advantages:

- No special surface treatment required

- Compatible with FR4 processing temperatures

- Lead-free assembly capable

- Cost reduction of 60-80% versus PTFE

Performance Specifications:

- RO4003C: Dk=3.38, Df=0.0027 at 10 GHz

- RO4350B: Dk=3.48, Df=0.0037 at 10 GHz

- Glass transition temperature: >280°C

- Thermal conductivity: 0.71 W/m·K

These materials enable high-volume production of multilayer PCB designs for 5G infrastructure and automotive applications.

Liquid Crystal Polymer: Next-Generation Technology

LCP substrates offer unique advantages for mmWave and moisture-sensitive applications:

Revolutionary Properties:

- Near-zero moisture absorption (<0.04%)

- Stable Dk/Df to 110 GHz

- Hermetic packaging capability

- Flexibility for conformable antennas

Manufacturing Considerations:

LCP processing presents challenges that limit widespread adoption:

- High lamination temperature (280-320°C)

- Limited thickness options

- Higher cost than ceramic-filled PTFE

- Specialized via metallization required

Despite challenges, LCP enables breakthrough designs in 5G antenna-in-package and aerospace applications.

Material Selection for Specific Frequency Bands

Sub-6 GHz Applications (Cellular, WiFi, IoT)

The sub-6 GHz spectrum hosts the majority of wireless communication systems, requiring cost-effective materials with moderate performance.

Recommended Material Matrix:

| Application | Frequency | Recommended Materials | Key Requirements |

|---|---|---|---|

| 4G/5G Infrastructure | 0.7-3.5 GHz | RO4350B, I-Tera MT40 | Df <0.01, stable outdoors |

| WiFi 6/6E | 2.4/5/6 GHz | RO4003C, Astra MT77 | Low cost, high volume |

| IoT/LPWAN | 0.4-1 GHz | FR408HR, N4000-13EP | Adequate performance |

Design Optimization Strategies:

For sub-6 GHz designs, material thickness significantly impacts performance and cost. Using thinner substrates reduces material cost while maintaining electrical performance, though it requires tighter manufacturing tolerances.

Optimal thickness selection:

- 0.508mm (20 mil): Standard for general purpose

- 0.254mm (10 mil): High-density designs

- 1.524mm (60 mil): Power amplifier applications

mmWave Applications (5G, Radar, Satellite)

Millimeter wave frequencies demand premium materials with exceptional electrical properties and dimensional stability.

24-40 GHz Band Requirements:

Surface roughness becomes critical at mmWave frequencies. Standard electrodeposited copper (Rz=5-7μm) causes significant additional loss above 20 GHz.

Material Selection Criteria:

- Loss tangent: <0.002 mandatory

- Copper roughness: <2μm Rz required

- Glass weave effect: Minimize with spread glass or ceramic fill

- Thickness tolerance: ±10% maximum

Recommended Solutions:

For 28 GHz 5G:

- Rogers RO3003: Dk=3.00, Df=0.0013

- Taconic TLX-8: Dk=2.55, Df=0.0019

- Isola Tachyon-100G: Dk=3.02, Df=0.0021

For 77 GHz Automotive Radar:

- Rogers RO3003G2: Enhanced for automotive

- RT/duroid 5880LZ: Ultra-low Dk=1.96

- Megtron 7: Df=0.001 at W-band

Manufacturing Process Compatibility

PTFE Processing Requirements

PTFE materials demand specialized manufacturing processes that impact both cost and lead time:

Critical Process Modifications:

Surface Preparation: Traditional PTFE requires aggressive surface treatment for copper adhesion:

- Sodium etching: Creates microporous surface

- Plasma treatment: Environmentally friendly alternative

- Adhesion promoters: Silane coupling agents

Lamination Parameters:

- Temperature: 280-320°C (vs. 185°C for FR4)

- Pressure: 50-150 PSI (vs. 300-400 PSI)

- Cool-down rate: <3°C/minute critical

- Atmosphere: Nitrogen purge recommended

Cost Impact Analysis:

PTFE processing adds 30-50% to manufacturing cost through:

- Longer cycle times (4-6 hours vs. 2 hours)

- Specialized tooling requirements

- Lower panel utilization

- Additional quality control steps

Hybrid Construction Strategies

Combining different materials optimizes cost while maintaining RF performance where needed:

Selective High-Performance Layers:

A typical 8-layer hybrid stackup:

- Layers 1-2: Rogers RO4003C for RF signals

- Layers 3-6: Standard FR4 for digital/power

- Layers 7-8: FR4 for mechanical support

This approach reduces material cost by 60% while maintaining critical RF performance.

Sequential Lamination Considerations:

Hybrid constructions require careful process control:

- CTE matching between materials

- Compatible processing temperatures

- Adhesion between dissimilar materials

- Warpage control through balanced construction

Environmental Testing and Reliability

Moisture Absorption Effects

Moisture significantly impacts high-frequency performance, particularly for non-PTFE materials:

Performance Degradation Mechanisms:

- Increased dielectric constant (water Dk=80)

- Higher loss tangent

- Delamination risk during assembly

- Dimensional instability

Material Comparison After 24hr Water Immersion:

| Material | Moisture Absorption | Dk Change | Df Change |

|---|---|---|---|

| RT/duroid 5880 | 0.02% | <0.5% | <5% |

| RO4003C | 0.06% | <1% | <10% |

| FR4 | 0.8% | >5% | >50% |

| LCP | 0.04% | <0.5% | <5% |

Thermal Cycling Performance

RF materials must maintain properties across wide temperature ranges:

Standard Test Conditions:

- Temperature range: -55°C to +125°C

- Ramp rate: 10°C/minute

- Dwell time: 10 minutes minimum

- Cycles: 100-1000 depending on application

Critical Failure Modes:

- Copper trace cracking from CTE mismatch

- Via barrel fatigue

- Delamination at material interfaces

- Solder joint failure

Materials with matched CTE to copper (17 ppm/°C) show superior reliability. Rogers TC series and Arlon AD series specifically address this requirement.

Advanced Applications and Emerging Technologies

Antenna-in-Package Integration

Modern 5G and radar systems integrate antennas directly into the package substrate:

Material Requirements:

- Consistent Dk for predictable antenna dimensions

- Low loss for efficiency

- Fine line capability for array elements

- Multilayer construction for feed networks

Recommended Materials:

- Rogers RO4835: Optimized for AiP applications

- Megtron 6: Low Dk glass cloth for consistency

- LCP: Ultimate integration density

Embedded Component Technologies

Embedding passive components within the PCB substrate reduces parasitics and improves RF performance:

Material Compatibility:

For Embedded Capacitors:

- High-K materials (Dk>30) for capacitor layers

- Compatibility with standard RF substrates

- Stable properties across frequency

For Embedded Resistors:

- Resistive foils or printed resistive materials

- Laser trimming capability

- Temperature stability <100 ppm/°C

Cost-Performance Optimization Strategies

Total Cost of Ownership Analysis

Material selection must consider complete lifecycle costs:

Cost Components Beyond Material Price:

- Processing complexity and yield

- Assembly process compatibility

- Testing and qualification requirements

- Field reliability and warranty costs

Example TCO Comparison (Relative to FR4=1.0):

| Material | Raw Cost | Processing | Assembly | Testing | TCO |

|---|---|---|---|---|---|

| FR4 | 1.0 | 1.0 | 1.0 | 1.0 | 1.0 |

| RO4350B | 3.5 | 1.2 | 1.0 | 1.2 | 2.8 |

| RT/duroid | 8.0 | 2.0 | 1.5 | 1.5 | 6.5 |

Design for Manufacturing Excellence

Optimizing designs for specific materials reduces cost and improves yield:

Best Practices:

- Standardize on common material thicknesses

- Minimize layer count through careful planning

- Use symmetric stackups to prevent warpage

- Consider panel utilization in layout

- Specify realistic tolerances based on material capabilities

Future Trends in High-frequency Materials

Next-Generation Material Development

Research focuses on breakthrough technologies:

Graphene-Enhanced Composites:

- Theoretical Df <0.0001

- Superior thermal conductivity

- Challenges in manufacturing scale-up

Aerogel Substrates:

- Ultra-low Dk approaching 1.0

- Mechanical fragility limits applications

- Potential for antenna applications

Bio-Based Materials:

- Sustainable alternatives to PTFE

- Performance approaching traditional materials

- Meeting environmental regulations

Industry Standardization Efforts

Standardization initiatives improve material availability and reduce costs:

IPC-4103 Slash Sheets: Standardized specifications enable second-sourcing:

- /11: RO4003C equivalent

- /13: RO4350B equivalent

- /14: High-frequency, low-loss materials

5G Material Specifications: Industry consortiums developing common specifications for 5G infrastructure materials, targeting:

- Dk tolerance: ±0.05

- Df: <0.003 at 28 GHz

- Cost: <5× FR4

Why Choose HILPCB for High-frequency Material Processing

HILPCB offers comprehensive expertise in high-frequency PCB materials with advanced processing capabilities:

Material Expertise:

- Full Rogers, Taconic, Arlon, Isola inventory

- Hybrid construction capabilities

- Custom stackup design support

- Material characterization services

Processing Excellence:

- PTFE-optimized lamination systems

- Plasma surface treatment

- Controlled impedance ±3%

- Sequential lamination for complex builds

Quality Assurance:

- IPC-A-600 Class 3 certification

- Network analyzer testing to 40 GHz

- Environmental testing capabilities

- Full traceability and documentation

Frequently Asked Questions

Q1: How do I select the right material for my specific frequency and application?

Start with frequency-dependent loss requirements. For <10 GHz, RO4000 series offers good performance/cost balance. For 10-40 GHz, consider RO3003 or similar low-loss materials. Above 40 GHz, premium PTFE materials like RT/duroid 5880 become necessary. Factor in environmental requirements, volume, and cost constraints for final selection.

Q2: What's the real difference between woven and non-woven glass reinforcement?

Woven glass creates periodic Dk variations (glass weave effect) that can cause signal integrity issues, particularly for differential pairs. Non-woven or ceramic-filled materials provide uniform dielectric properties but may have different mechanical characteristics. For critical impedance control, ceramic-filled or spread-glass materials are preferred.

Q3: Can I use lead-free assembly with PTFE materials?

Yes, but carefully control the reflow profile. Most PTFE materials handle 260°C peak temperature, but prolonged exposure causes degradation. Use ramp rates <3°C/second and minimize time above 250°C. Some materials like RO4835 are specifically optimized for lead-free assembly with multiple reflow cycles.

Q4: How does copper surface roughness affect my high-frequency design?

Surface roughness increases conductor loss proportionally to frequency. At 10 GHz, standard ED copper (Rz=5-7μm) adds ~0.5 dB/inch extra loss. At 28 GHz, this increases to ~1.5 dB/inch. Use low-profile copper (Rz<3μm) above 10 GHz and very-low-profile (Rz<1.5μm) above 20 GHz.

Q5: What thickness tolerance should I specify for controlled impedance?

For ±5% impedance tolerance, specify substrate thickness ±10% maximum. For ±3% impedance, require ±5% thickness tolerance. Remember that thickness variations have greater impact on microstrip than stripline configurations. Critical applications may require ±0.025mm absolute tolerance.

Q6: Are there cost-effective alternatives to Rogers materials?

Yes, several manufacturers offer compatible materials: Isola (I-Tera, Astra series), Taconic (RF-35, TLX series), Arlon (AD series), and Panasonic (Megtron series). These often provide similar performance at 20-30% lower cost. Verify electrical properties and processing compatibility before substituting.