The machine operator approached the control panel of a $2 million packaging line, ready to start the morning shift. Instead of the familiar green "Start" button, the touchscreen displayed only a black void. The HMI PCB had failed overnight, bringing the entire production line to a standstill and costing thousands in lost productivity per hour.

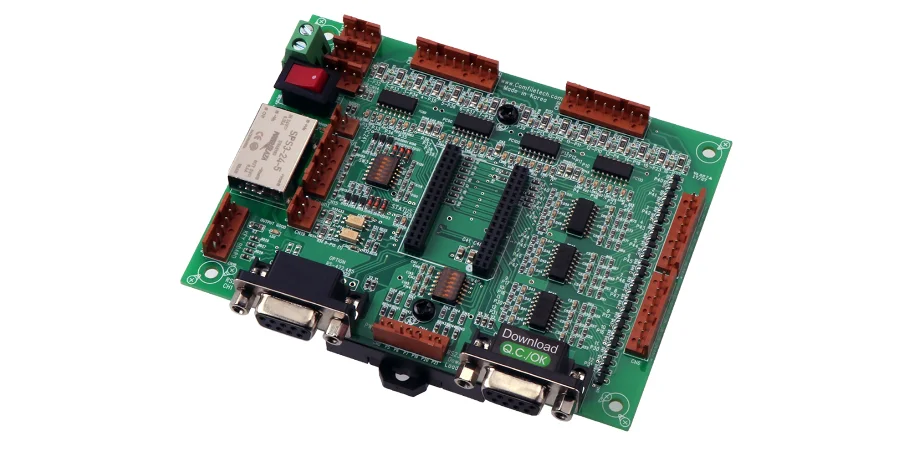

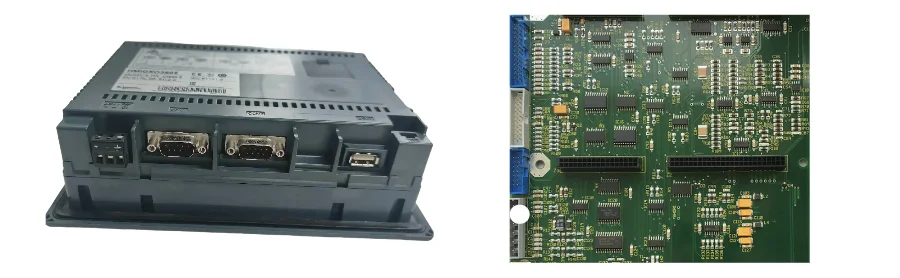

This scenario plays out daily in manufacturing facilities worldwide, highlighting why Human Machine Interface (HMI) PCB design demands exceptional reliability, intuitive functionality, and robust construction. At Highleap PCB Factory (HILPCB), we understand that HMI PCBs aren't just circuit boards—they're the critical communication bridge between human operators and complex industrial systems.

From simple membrane keypads to sophisticated multi-touch displays, HMI PCBs must withstand harsh industrial environments while providing responsive, error-free operation for years of continuous use.

Manufacturing Control Panel HMI Systems

Manufacturing environments demand HMI solutions that combine operational efficiency with exceptional durability. Control panels serve as command centers for complex production equipment, requiring PCB designs that handle multiple input types while providing clear visual feedback to operators.

Multi-Function Display Integration: Modern manufacturing HMIs integrate LCD or OLED displays with capacitive touch sensing on multilayer PCB constructions. These displays must render critical process data clearly while supporting touch gestures for navigation and control. PCB design requires careful signal routing to prevent interference between display drivers and touch sensing circuits.

Membrane Switch Arrays: Traditional membrane switches remain popular for manufacturing applications due to their sealed construction and tactile feedback. Flex PCB technology enables complex switch layouts with integrated LED backlighting for status indication. Membrane designs must accommodate millions of actuations while maintaining consistent electrical characteristics.

Process Monitoring Interfaces: Manufacturing HMI PCBs integrate multiple sensor inputs for real-time process monitoring. Temperature sensors, pressure transducers, and flow meters require dedicated analog conditioning circuits with appropriate filtering and isolation. Digital interfaces support communication with PLCs and SCADA systems through industrial protocols like Modbus and EtherNet/IP.

Emergency Stop Integration: Safety regulations require emergency stop functionality accessible from HMI panels. PCB designs must implement redundant stop circuits with proper isolation and fail-safe operation. Emergency stops typically use dedicated hardware interlocks independent of microprocessor control to ensure reliable operation under all conditions.

Environmental Sealing: Manufacturing environments expose HMI panels to oil mist, coolant spray, and cleaning chemicals. PCB designs require conformal coating and gasket interfaces that maintain IP65 or IP67 sealing ratings. Component selection emphasizes corrosion resistance and long-term stability under chemical exposure.

Medical Equipment Touch Interface Design

Medical device HMIs demand the highest levels of reliability and user safety, with PCB designs that support critical patient care applications while meeting stringent regulatory requirements.

Patient Monitoring Systems: ICU monitors and patient care devices use HMI PCBs that integrate high-resolution displays with touch control for alarm management and parameter adjustment. HDI PCB technology enables compact designs with fine-pitch components necessary for portable monitoring equipment.

Surgical Equipment Controls: Operating room equipment requires HMI interfaces that function reliably during critical procedures. Touch surfaces must support operation with surgical gloves while preventing accidental activation. PCB designs incorporate proximity sensing and configurable touch sensitivity to accommodate various glove types and operating conditions.

Diagnostic Equipment Interfaces: Medical imaging systems and laboratory analyzers use sophisticated HMI PCBs that manage complex workflows and data visualization. High-speed processors handle image rendering and user interface graphics while maintaining real-time responsiveness for operator interactions.

Biocompatibility Requirements: Medical HMI PCBs often require biocompatible materials and coatings for applications involving patient contact. Material selection must comply with ISO 10993 standards while maintaining electrical performance and manufacturing feasibility.

Sterilization Compatibility: Healthcare applications may require HMI PCBs that withstand autoclave sterilization or chemical disinfection. Component selection and material specifications must account for repeated thermal cycling and chemical exposure without degradation of electrical or mechanical properties.

Automotive Dashboard and Infotainment HMI

Automotive applications present unique challenges for HMI PCB design, combining consumer electronics expectations with automotive reliability requirements across extreme temperature ranges and vibration conditions.

Climate Control Interfaces: HVAC control panels integrate multiple input methods including rotary encoders, push buttons, and touch controls. PCB designs must handle automotive electrical noise while providing precise temperature and airflow control. High-Tg PCB materials ensure dimensional stability under dashboard temperature extremes.

Infotainment System Controls: Modern vehicles integrate smartphone-like touch interfaces for entertainment and navigation functions. Large touchscreen HMI PCBs require high-speed processors and graphics accelerators while maintaining automotive EMC compliance. Signal integrity becomes critical for high-resolution display interfaces and wireless communication modules.

Driver Information Displays: Instrument cluster HMIs provide critical driving information through configurable displays and warning indicators. PCB designs must support automotive communication protocols like CAN and LIN while providing failsafe operation for safety-critical information display.

Steering Wheel Controls: Space constraints in steering wheel assemblies require miniaturized HMI PCBs with integrated touch sensors and haptic feedback systems. Flexible or rigid-flex PCB constructions accommodate complex steering wheel geometries while maintaining reliable electrical connections through steering rotation.

Environmental Resilience: Automotive HMI PCBs must operate reliably from -40°C to +85°C while withstanding vibration and shock loads from vehicle operation. Conformal coating and robust component mounting techniques ensure long-term reliability under automotive operating conditions.

Home Appliance Control Panel Solutions

Consumer appliances increasingly incorporate sophisticated HMI interfaces that blend aesthetic appeal with functional control requirements, demanding PCB designs that support cost-effective manufacturing while ensuring reliable operation.

Kitchen Appliance Interfaces: Ovens, dishwashers, and refrigerators use HMI PCBs that integrate membrane keypads with digital displays for cooking programs and status indication. Steam, heat, and chemical exposure from cleaning products require robust PCB protection and material selection.

Washing Machine Controls: Laundry appliances require HMI PCBs that handle moisture exposure while providing intuitive cycle selection and progress indication. Sealed membrane constructions with integrated LED backlighting provide clear operation guidance while preventing water ingress.

Smart Home Integration: Modern appliances incorporate WiFi and Bluetooth connectivity for smartphone app control and home automation integration. HMI PCBs must balance local control functionality with wireless communication capabilities while maintaining cost targets for consumer markets.

Energy Efficiency Displays: Energy-conscious consumers demand detailed consumption information from appliances. HMI PCBs integrate power monitoring circuits with graphical displays that show energy usage patterns and efficiency recommendations in user-friendly formats.

Building Automation and HVAC Control

Commercial building systems rely on HMI interfaces for facility management and energy optimization, requiring PCB designs that support networking capabilities while providing reliable local control functionality.

Thermostat and Climate Control: Modern building thermostats integrate touchscreen interfaces with occupancy sensors and wireless connectivity. PCB designs must handle battery power management for wireless operation while supporting sophisticated scheduling and zone control algorithms.

Lighting Control Panels: Commercial lighting systems use HMI PCBs that manage complex lighting scenes and energy optimization schedules. Touch interfaces provide intuitive control while supporting integration with building automation systems through standard communication protocols.

Access Control Integration: Security and access control systems incorporate HMI PCBs with card readers, biometric sensors, and communication interfaces. Rigid-flex PCB designs accommodate space constraints while providing reliable connections between different functional sections.

Energy Management Systems: Building energy management relies on HMI interfaces that visualize consumption patterns and enable optimization decisions. Large touchscreen displays require high-resolution graphics capabilities while supporting real-time data acquisition from multiple building systems.

Our SMT assembly capabilities ensure precise component placement for complex HMI PCB designs, while comprehensive testing validates functionality across all environmental conditions. Design verification using our 3D viewer helps optimize mechanical interfaces before production.

Frequently Asked Questions

Q: What's the difference between resistive and capacitive touch HMI PCBs? Resistive touch offers better accuracy with gloved operation and stylus input, while capacitive provides better durability and multi-touch capability. Choice depends on application requirements and environmental conditions.

Q: How do you ensure HMI PCB reliability in harsh industrial environments? Use industrial-grade components, conformal coating, proper sealing techniques, and extensive environmental testing including temperature cycling, humidity, and vibration qualification.

Q: Can HMI PCBs integrate wireless connectivity without interference issues? Yes, with proper PCB layout techniques including RF shielding, antenna placement optimization, and careful filtering of power supplies and digital circuits near wireless modules.

Q: What display technologies work best for HMI applications? LCD provides cost-effective solutions for most applications, while OLED offers better contrast and viewing angles. E-ink displays excel in low-power applications requiring sunlight readability.

Q: How important is haptic feedback in HMI PCB design? Haptic feedback significantly improves user experience by providing confirmation of touch inputs, especially important in applications where operators cannot always look at the interface while controlling equipment.