The evolution of mechanical keyboards has embraced modularity through Hot-Swappable Mechanical Keyboard PCBs, revolutionizing how enthusiasts customize and maintain their typing experience. Unlike traditional soldered boards, modern hotswap designs eliminate the need for soldering, allowing users to experiment with different switch types and quickly replace worn components. From entry-level socket PCBs that make the hobby more accessible, to advanced modular mechanical keyboard PCBs supporting multiple layouts, today’s hot-swap technology democratizes customization while maintaining professional-grade reliability.

At HILPCB, we deliver specialized manufacturing solutions optimized for hot-swappable applications, integrating robust Kailh socket implementations, Mill-Max socket compatibility, and reinforced pad designs. Whether you need a budget-friendly hotswap keyboard PCB or a premium mechanical keyboard PCB with per-key RGB and wireless connectivity, our processes ensure long-term socket durability, precise alignment, and consistent electrical performance through thousands of switch swaps.

Hot-Swappable Keyboard PCB Architecture and Socket Integration

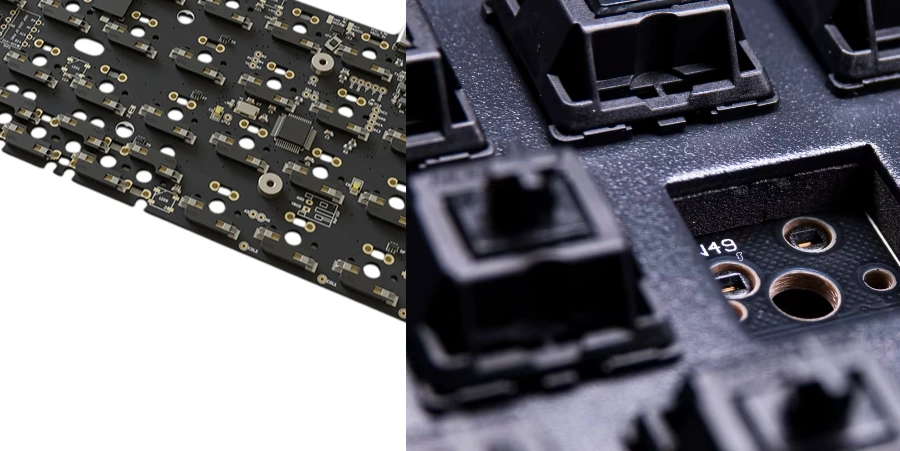

A robust Hot-Swappable Keyboard PCB must balance mechanical durability with electrical reliability while accommodating various socket types and switch standards. The core architecture for Hotswap PCB includes:

- Reinforced copper pads for Socket Keyboard PCB durability through repeated insertions

- Optimized trace routing around Kailh Socket PCB footprints for signal integrity

- Ground plane design for Modular Keyboard PCB EMI reduction and stability

- Switch Socket PCB alignment features ensuring perfect switch positioning

- Multi-layout support with alternative socket placements for Hotswap Keyboard PCB

- Strengthened via placement preventing pad lifting during switch removal

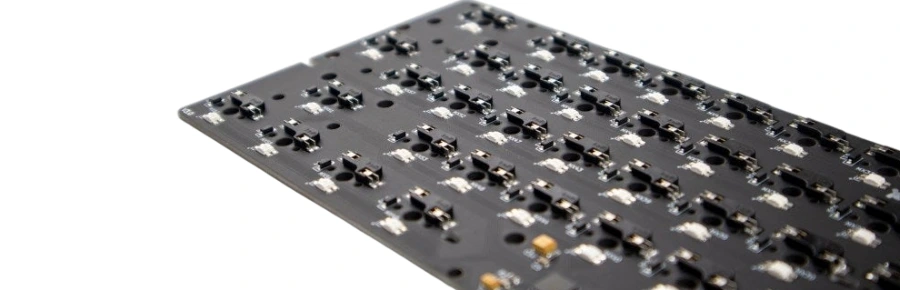

Socket Keyboard PCB designs typically employ 2-4 layer multilayer PCB structures with 2oz copper for enhanced pad adhesion. The challenge of Switch Socket PCB design lies in maintaining structural integrity while accommodating tight component spacing. Modular Keyboard PCB implementations enable layout flexibility without compromising socket stability.

Advanced Gaming Hotswap PCB models integrate optical switch sockets for zero-debounce performance while maintaining hot-swap functionality for ultimate gaming responsiveness.

Specialized Manufacturing for Hot-Swap Socket Implementation

Our production capabilities are specifically optimized for the mechanical demands of Hot-Swappable Keyboard PCB and Hotswap PCB manufacturing:

- Socket Keyboard PCB: Enhanced pad size and copper thickness for maximum adhesion

- Kailh Socket PCB: Precision placement with ±0.05mm tolerance for switch alignment

- Mill-Max Socket PCB: Through-hole socket insertion with selective wave soldering

- Modular Keyboard PCB: ENIG surface finish for corrosion resistance and contact reliability

- Switch Socket PCB: Reinforced substrate materials preventing flexing and cracking

- Hotswap Keyboard PCB: 100% electrical testing of socket connections

SMT assembly lines feature specialized fixtures for Hot-Swappable Keyboard PCB socket placement, ensuring consistent orientation and solder joint quality. Our turnkey assembly services for Socket Keyboard PCB include socket insertion force testing and switch compatibility verification.

Socket Technology and Durability Engineering for Hotswap PCB Design

Implementing reliable hot-swap functionality requires careful consideration of socket selection, PCB reinforcement, and manufacturing techniques to ensure long-term durability and consistent performance.

Socket Types and Applications

- Kailh Hot-Swap Sockets SMD mounting for automated assembly, rated for 100+ insertion cycles, compatible with MX-style switches.

- Mill-Max 0305/7305 Sockets Through-hole design for maximum durability, 1000+ insertion cycles, premium option for enthusiast builds.

- Outemu Sockets Budget-friendly alternative with good compatibility, suitable for entry-level hot-swap keyboards.

- Optical Switch Sockets Specialized design for optical switches, combining hot-swap convenience with optical sensing technology.

- Low-Profile Sockets Choc-compatible sockets for slim mechanical keyboards, maintaining hot-swap functionality in compact designs.

PCB Reinforcement Strategies

- Pad Design Optimization Enlarged annular rings and teardrop transitions distribute mechanical stress during switch insertion/removal.

- Via Stitching Multiple vias around socket pads increase copper adhesion and prevent delamination.

- Substrate Selection High-Tg FR4 materials resist flexing and maintain dimensional stability under mechanical stress.

- Copper Weight 2oz or heavier copper layers provide superior pad adhesion and current carrying capacity.

Hot-Swappable Keyboard PCB Applications and Market Segments

Hot-Swappable Keyboard PCB technology serves diverse user groups and keyboard categories:

- Hot-Swappable Keyboard PCB for Enthusiast Custom Builds

- Hotswap PCB for Entry-Level Mechanical Keyboards

- Socket Keyboard PCB for Office and Productivity Keyboards

- Modular Keyboard PCB for Experimental and Prototype Designs

- Switch Socket PCB for Gaming and Esports Applications

- Kailh Socket PCB for Mass Production Consumer Models

- Mill-Max Socket PCB for Premium and Boutique Keyboards

Hotswap Keyboard PCB applications increasingly include wireless modules with Socket Keyboard PCB for portable gaming setups. Our rigid-flex PCB capabilities enable innovative Modular Keyboard PCB designs for split and ergonomic configurations.

Integrated Ecosystem Solutions for Hot-Swap Keyboard Manufacturing

Beyond core Hot-Swappable Keyboard PCB manufacturing, we provide comprehensive ecosystem solutions:

Socket Sourcing and Validation:

- Kailh socket procurement with batch consistency verification

- Mill-Max socket availability and lead time management

- Alternative socket compatibility testing

- Socket force and retention specifications

Quality Assurance Testing:

- Insertion/extraction force measurement

- Contact resistance monitoring through swap cycles

- Socket alignment and coplanarity verification

- Accelerated life testing for durability validation

Assembly Support Services:

- Socket orientation guides and assembly documentation

- Selective soldering programs for through-hole sockets

- Rework procedures for socket replacement

- Switch compatibility matrices and testing

Aesthetic and Material Options for Hot-Swappable PCBs

Modern mechanical keyboards are not just about performance — they are also lifestyle products, where aesthetics and build quality matter as much as functionality. At HILPCB, we provide a wide range of material and design options for Hot-Swappable Keyboard PCBs that help brands and enthusiasts create keyboards with unique visual appeal and superior durability.

Material and Color Options

- Transparent PCBs – Enhance the glow of RGB lighting, delivering a clean, futuristic look ideal for gaming and showcase builds.

- Colored PCBs – White, red, blue, green, or fully custom colors that match your brand’s identity or product theme.

- Black Core (Black-FR4) PCBs – A premium choice for luxury keyboards, offering a bold and professional appearance with superior rigidity.

- Specialty Substrates – High-Tg FR4, matte/gloss finishes, or reinforced composites for enhanced durability and thermal stability.

Benefits of Custom Aesthetic PCBs

- Brand Differentiation – Colored or transparent PCBs set your product apart in a crowded market.

- User Appeal – Eye-catching designs increase the perceived value of your keyboards.

- Seamless Integration – Aesthetic PCBs combine perfectly with transparent or colored cases, keycaps, and backplates for a fully customized experience.

At HILPCB, we believe a Hot-Swappable Keyboard PCB should not only perform flawlessly but also look stunning. By combining material innovation with aesthetic customization, we help brands deliver keyboards that captivate both the eye and the fingertips.

Why Choose HILPCB for Hot-Swappable Keyboard PCB Manufacturing

At HILPCB, we understand that the hot-swappable keyboard market requires more than just functional PCBs—it demands durability, precision, and aesthetics that stand out in a competitive landscape. Every board we produce is engineered for socket reinforcement, long-term reliability, and visual appeal, ensuring your products deliver a premium experience inside and out. With ISO 9001:2015 and IPC-A-610 Class 2 certifications, we guarantee strict quality control and consistency across every production run.

Our capabilities go beyond basic PCB production. We offer custom aesthetic options such as black-core laminates, transparent solder masks for RGB diffusion, and full-color PCBs tailored to your branding. Combined with high-Tg FR4 for heat resistance and ENIG finishes for both performance and style, our boards are designed to be both technically robust and visually distinctive. Whether you need Kailh, Outemu, or Mill-Max socket integrations, we optimize pad design, copper weight, and reinforcement strategies to extend the lifespan of every hot-swap connection.

From prototyping to high-volume manufacturing, HILPCB delivers end-to-end support for your keyboard projects. Our engineering team provides socket selection guidance, PCB reinforcement design, and functional testing, while our assembly lines ensure precise SMT/DIP integration for controllers, LEDs, and sockets. Whether you are developing entry-level hot-swap keyboards or premium enthusiast builds, we provide scalable solutions that combine engineering precision, aesthetic flexibility, and long-term durability—helping your brand bring truly outstanding mechanical keyboards to market.

Frequently Asked Questions – Hot-Swappable Keyboard PCB

Q1: What are the main advantages of Hot-Swappable Keyboard PCB designs?

A: Hot-swap PCBs allow switch changes without soldering, enable easy customization and maintenance, reduce repair costs, and make mechanical keyboards accessible to non-technical users while preserving resale value.

Q2: How many insertion cycles can quality Hotswap PCB sockets handle?

A: Kailh sockets typically handle 100+ cycles, while Mill-Max sockets can exceed 1000 cycles. Actual lifespan depends on insertion technique, switch pin condition, and PCB reinforcement quality.

Q3: What's the difference between Kailh and Mill-Max sockets for Socket Keyboard PCB?

A: Kailh sockets are SMD-mounted, more affordable, and easier to manufacture at scale. Mill-Max are through-hole, more durable, provide better retention, but cost more and require manual assembly.

Q4: Can Hot-Swappable Keyboard PCB support multiple switch types?

A: Most hot-swap PCBs support MX-style switches (Cherry, Gateron, Kailh, etc.). Some designs include additional sockets for Alps or Choc switches, but this requires specific socket types and PCB layouts.

Q5: How to prevent socket damage on Modular Keyboard PCB?

A: Use proper switch insertion technique (straight down, not angled), ensure switch pins are straight, avoid excessive force, and design PCBs with reinforced pads and proper copper weight.

Q6: Are hot-swap sockets compatible with LED switches on Switch Socket PCB?

A: Yes, most hot-swap sockets support 3-pin and 5-pin MX switches with LEDs. The PCB must include appropriate LED pads and resistors. Some sockets may partially block SMD LEDs, affecting brightness.