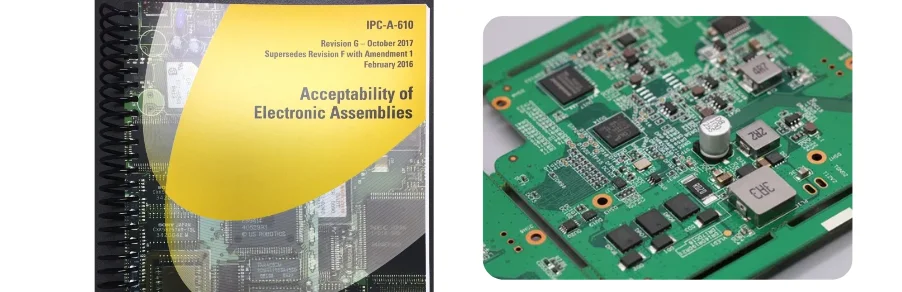

The difference between a reliable electronic product and a field failure often lies in the quality of PCB assembly processes and inspection procedures. When solder joints fail, components shift during operation, or assembly defects cause intermittent faults, the resulting warranty claims, customer dissatisfaction, and brand damage can far exceed the cost of proper quality control. IPC-A-610 PCB assembly standards establish the definitive criteria for determining whether electronic assemblies meet acceptable quality levels, providing detailed visual and measurable requirements for solder joints, component placement, and overall assembly quality.

Our IPC-A-610 PCB assembly processes implement comprehensive quality inspection procedures and acceptance criteria that ensure every assembled board meets the stringent requirements for reliable electronic products, minimizing field failures and maximizing customer satisfaction.

Quality Electronic Assembly with IPC-A-610 Standards Implementation

Achieving consistent IPC-A-610 PCB assembly quality requires systematic implementation of standardized procedures, comprehensive training programs, and rigorous inspection protocols that address every aspect of the assembly process from component placement through final quality verification.

1. Comprehensive Assembly Quality Framework

IPC-A-610 PCB standards establish a complete quality framework that addresses all critical aspects of electronic assembly. The standard defines three distinct quality classes—Class 1 for general electronic products, Class 2 for dedicated service electronics, and Class 3 for high-performance applications—each with progressively stricter acceptance criteria that match reliability requirements with appropriate quality levels.

Our implementation incorporates automated inspection systems that verify component placement accuracy, solder joint quality, and overall assembly integrity against IPC-A-610 criteria. Statistical quality monitoring tracks defect rates and trends, enabling continuous process improvement and defect prevention strategies that maintain consistent assembly quality across all production volumes.

2. Advanced Solder Joint Quality Assessment

Solder joint quality represents the most critical aspect of IPC-A-610 compliance, directly affecting both electrical performance and mechanical reliability. The standard provides detailed criteria for evaluating solder joint shape, wetting characteristics, and dimensional requirements that ensure reliable connections throughout the product's operational lifetime.

Our inspection procedures incorporate both automated optical inspection (AOI) and skilled human inspectors trained to IPC-A-610 standards, ensuring comprehensive evaluation of solder joint quality for multilayer PCB assemblies and complex backplane PCB configurations. X-ray inspection validates hidden solder joints in Ball Grid Array (BGA) and other area-array components, providing complete quality assurance coverage.

3. Component Placement and Orientation Verification

Proper component placement and orientation directly impact both functionality and reliability, making placement verification a critical element of IPC-A-610 compliance. The standard establishes specific tolerances for component position, rotation, and standoff height that ensure optimal electrical performance and mechanical stability.

Automated placement verification systems measure component position and orientation with sub-millimeter accuracy, automatically flagging assemblies that exceed IPC-A-610 tolerances. Special attention is given to polarized components, ensuring correct orientation to prevent damage during power-up and operation.

4. Cleanliness and Contamination Control

Assembly cleanliness significantly affects long-term reliability, particularly for high-frequency PCB applications where contamination can cause signal integrity issues. IPC-A-610 establishes cleanliness standards that address flux residues, particle contamination, and other assembly-related contaminants that could affect performance.

Our cleaning processes and contamination control procedures ensure assemblies meet IPC-A-610 cleanliness requirements, with validation testing that confirms adequate removal of flux residues and other potentially harmful contaminants. Environmental controls maintain clean assembly conditions throughout the production process.

5. Documentation and Traceability Systems

IPC-A-610 compliance requires comprehensive documentation that provides complete traceability throughout the assembly process. Our quality management systems maintain detailed records of component lots, assembly procedures, inspection results, and any rework or repair activities that affect final product quality.

Digital documentation systems provide instant access to assembly records, enabling rapid quality investigations and continuous improvement initiatives. Statistical analysis of quality data identifies trends and opportunities for process optimization that enhance both quality and efficiency.

By implementing comprehensive IPC-A-610 assembly procedures, we deliver electronic assemblies that meet the highest quality standards while maintaining cost-effective production processes. This systematic approach ensures reliable products that minimize field failures and support long-term customer satisfaction across diverse application requirements.

Managing Thermal Profiles and Soldering Process Control in IPC-A-610 PCB Assembly

Thermal management during the soldering process represents a critical factor in achieving IPC-A-610 compliance, directly affecting solder joint quality, component reliability, and overall assembly performance. Proper thermal profiling ensures optimal solder flow while preventing component damage or substrate degradation.

Key thermal management considerations include:

- Precise temperature profiling for different component types and thermal masses across the assembly

- Ramp rate control to prevent thermal shock and component cracking during heating and cooling phases

- Peak temperature management ensuring adequate solder reflow while avoiding component or substrate damage

- Time above liquidus optimization providing sufficient wetting time without excessive intermetallic formation

- Metal core PCB considerations for assemblies requiring enhanced thermal dissipation

- Thermal monitoring systems that validate profile consistency and provide process control feedback

These thermal management strategies ensure consistent solder joint formation that meets IPC-A-610 quality requirements while protecting sensitive components and maintaining substrate integrity throughout the assembly process.

Accelerating Quality Implementation and Training Programs

Rapid Quality System Deployment

Implementing IPC-A-610 standards requires comprehensive training programs and quality system development that can impact production timelines. Efficient implementation strategies minimize disruption while ensuring thorough compliance with standard requirements.

Integrated Training and Certification Workflow

Our IPC-A-610 implementation process combines:

- Instructor-Led Training — comprehensive classroom instruction covering all aspects of IPC-A-610 requirements

- Hands-On Practical Training — real assembly evaluation using actual production examples and defect samples

- Certification Testing — validated assessment ensuring thorough understanding of acceptance criteria

Reduced Implementation Time and Quality Risk

By providing structured training programs and implementation support, we accelerate quality system deployment while ensuring consistent application of IPC-A-610 standards across all assembly operations. This systematic approach reduces the learning curve and ensures reliable quality implementation.

Continuous Improvement and Standards Updates

Quality system implementation enables organizations to:

- Maintain current knowledge of IPC-A-610 revisions and updates

- Implement best practices based on industry experience and feedback

- Develop custom quality procedures that exceed standard requirements

- Establish quality metrics and monitoring systems that support continuous improvement

Customization for Diverse Assembly Applications

IPC-A-610 PCB assembly standards address a wide range of electronic assembly applications, from simple through-hole assemblies to complex mixed-technology boards incorporating various component types, thermal requirements, and reliability specifications. Our expertise spans multiple assembly configurations, enabling optimized quality procedures for specific application requirements.

We support specialized assembly requirements including ceramic PCB substrates requiring specialized handling procedures, fine-pitch component assembly with enhanced placement accuracy requirements, and high-reliability assemblies requiring additional inspection and testing beyond standard IPC-A-610 requirements.

For applications with unique environmental or performance requirements, we develop custom quality procedures that incorporate IPC-A-610 principles while addressing application-specific challenges. These procedures ensure comprehensive quality coverage while maintaining cost-effective assembly processes.

Our box build assembly services extend IPC-A-610 quality principles to complete system assembly, ensuring consistent quality standards throughout the entire product assembly process from individual PCBs through final system integration and testing.

Comprehensive Quality Management and Inspection Systems

Delivering consistent IPC-A-610 compliance requires more than individual inspection procedures—it demands integrated quality management systems that address every aspect of assembly quality from incoming materials through final product delivery. We provide end-to-end quality management that encompasses supplier qualification, in-process monitoring, comprehensive inspection procedures, and continuous improvement programs.

Our quality systems incorporate advanced inspection technologies including automated optical inspection (AOI), X-ray systems for hidden solder joint evaluation, and in-circuit testing that validates electrical performance alongside visual quality assessment. These technologies provide comprehensive quality coverage while maintaining efficient production throughput.

Quality data management systems provide real-time visibility into assembly quality trends, enabling proactive quality management and immediate corrective action when quality issues are detected. Statistical analysis capabilities support both immediate quality control and long-term process improvement initiatives.

From prototype assembly validation through high-volume production quality management, our integrated approach ensures consistent IPC-A-610 compliance while supporting cost-effective assembly processes. Whether developing new products or optimizing existing assembly operations, our quality management expertise provides the foundation for reliable electronic assemblies that meet the demanding requirements of modern electronic products.