Medical LED applications demand uncompromising quality, precise spectral control, and absolute reliability. From surgical lighting requiring perfect color rendering to phototherapy systems delivering calibrated therapeutic doses, medical LED PCBs must meet stringent regulatory requirements while maintaining consistent performance. Our ISO 13485 certified manufacturing processes deliver medical-grade LED circuit boards supporting life-critical healthcare applications with full traceability and documentation.

Medical LED Applications and Clinical Requirements

Hospitals rely on LED illumination for diagnosis, therapy, and patient care—and Highleap PCB Factory delivers the manufacturing and PCB assembly quality those clinical outcomes depend on.

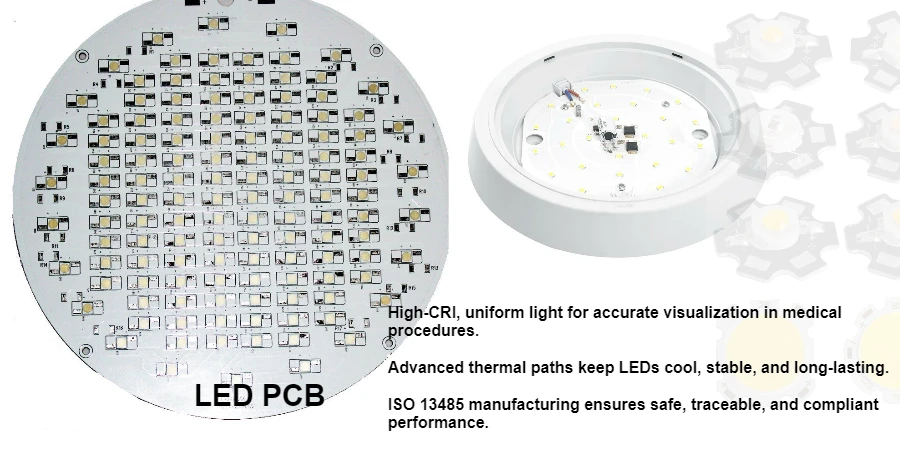

Surgical & Examination Lighting: OR luminaires demand accurate tissue rendition and uniform fields. Our medical LED boards are engineered for CRI > 95 and R9 > 90 with tunable CCT (3000–6500 K), tight flux matching, and precise optical alignment—so surgeons see exactly what matters, case after case. For sustained output and low drift, we pair optical design with robust thermal paths and closed-loop current control.

Phototherapy & Therapeutic Applications: From neonatal jaundice (450–470 nm) to UV dermatology and red/near-IR wound care, dose matters. We build modules with spectral stability within ±5 nm, uniform irradiance across the treatment area, and safety interlocks for accurate dosimetry. Where extreme heat and wavelength stability are critical, Ceramic PCB substrates provide excellent thermal conductivity and reliability.

Diagnostic & Imaging Systems: Endoscopy, microscopy, and dental curing tools need compact, flicker-free, synchronized light. Our miniaturized architectures integrate drivers, sensing, and shielding while fitting tight envelopes—leveraging Rigid-Flex PCB for bend-through pathways and HDI PCB for dense, high-reliability interconnects in handheld and catheter-based instruments.

Regulatory Compliance and Medical Standards

Medical device regulations ensure patient safety and product effectiveness.

IEC 60601 Safety Requirements

Medical electrical equipment must meet comprehensive safety standards:

- Electrical Safety: Isolation barriers preventing patient leakage currents

- Thermal Protection: Surface temperature limits preventing burns

- Mechanical Safety: Robust construction preventing component detachment

- EMC Compliance: Electromagnetic compatibility in hospital environments

- Risk Management: ISO 14971 risk analysis throughout design

Our design process incorporates safety requirements from concept. Creepage and clearance distances exceed minimum requirements. Protection circuits prevent single-fault hazards. Type testing validates compliance before production.

ISO 13485 Quality Management

Medical device quality systems ensure consistent manufacturing:

- Design Controls: Documented development process with verification/validation

- Process Validation: Statistical confirmation of manufacturing capability

- Traceability: Complete records from components to finished devices

- Corrective Action: Systematic problem resolution and prevention

- Management Review: Regular assessment of quality system effectiveness

Device history records maintain complete production documentation. Change control prevents unauthorized modifications. Supplier management ensures component quality and availability.

Biocompatibility and Material Selection

Patient contact applications require biocompatible materials.

Surface Material Requirements: LED PCBs in direct or indirect patient contact must use approved materials:

- USP Class VI certified substrates and coatings

- Non-toxic solder masks and adhesives

- Heavy metal-free (RoHS compliant) components

- Low-outgassing materials for enclosed spaces

- Antimicrobial coatings for infection control

For high-power medical LED applications, high thermal PCB materials ensure reliable heat dissipation while maintaining biocompatibility. Cytotoxicity testing validates material safety. Sensitization and irritation testing ensures patient compatibility. Chemical resistance to cleaning agents maintains integrity. Sterilization compatibility (EtO, gamma, autoclave) preserves functionality.

Optical Materials: Light delivery components require special consideration:

- UV-stable materials preventing degradation

- Optical-grade polymers maintaining transparency

- Anti-reflective coatings improving efficiency

- Diffusion materials ensuring uniform output

- Protective windows preventing contamination

Spectral transmission testing verifies optical properties. Aging tests confirm long-term stability. Cleaning protocol validation ensures maintainability.

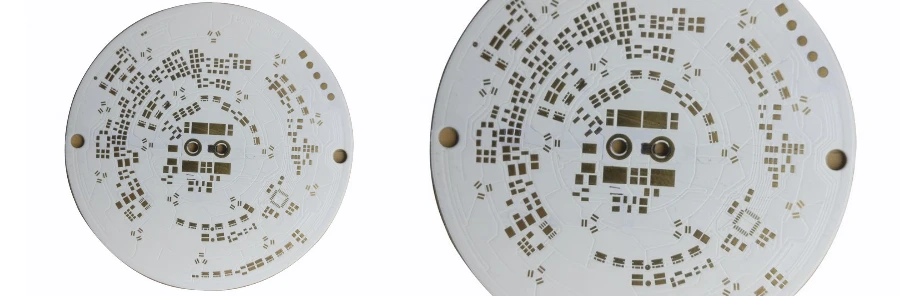

Precision Manufacturing for Medical Applications

Medical LED PCBs demand exceptional manufacturing control.

Clean Room Assembly

Contamination control ensures product purity:

- ISO Class 7 Environment: Controlled particles and microorganisms

- Personnel Training: Gowning procedures and handling protocols

- Material Control: Cleaned and validated components

- Environmental Monitoring: Particle counts and microbial testing

- Equipment Maintenance: Calibrated and validated processes

ESD protection prevents component damage. Humidity control prevents moisture-related defects. Temperature stability ensures consistent processing. Documentation tracks environmental conditions.

Process Validation and Control

Manufacturing processes require statistical validation:

- IQ/OQ/PQ Protocols: Installation, operational, and performance qualification

- Process Capability Studies: Cpk >1.33 for critical parameters

- Measurement System Analysis: Gauge R&R confirming measurement accuracy

- Statistical Process Control: Real-time monitoring and adjustment

- Validation Master Plan: Comprehensive validation strategy

First article inspection confirms new designs. In-process controls maintain quality. Final testing validates specifications. Periodic revalidation ensures continued capability.

Thermal Management for Medical Reliability

In medical devices, thermal design isn’t optional—it’s the baseline for safety, color stability, and lifetime. As your PCB manufacturing and PCB assembly partner, Highleap PCB Factory locks in junction-temperature targets, margins, and compliance from day one, combining DFM reviews with thermal simulation so surgical lighting, phototherapy, and imaging systems stay stable under 24/7 clinical duty.

We take a “passive-first” approach that shortens the heat path before adding forced air or liquid cooling. Material choices do the heavy lifting: High-Thermal PCB stack-ups, Metal Core PCB (MCPCB) bases for high-power arrays, and Ceramic PCB (AlN/Al₂O₃) for medical and high-reliability builds—all engineered to lower junction temperature, reduce color shift, and preserve optical output.

On the production side, our clean-process SMT Assembly delivers fine-pitch placement, ESD control, and full lot traceability. We integrate on-board sensing and over-temp/current protection, then verify with accelerated life, thermal cycling, and humidity stress—helping you consistently hit L70 ≥ 50,000 h and ≤ 3-step MacAdam targets. Choose Highleap PCB Factory for concept-to-scale thermal performance you can measure—and market.

Specialized Medical LED Technologies

Advanced applications require innovative LED PCB solutions.

Miniaturized Medical Devices

Implantable and wearable devices demand extreme miniaturization:

- Flexible PCBs: Conforming to anatomical structures using flex PCB technology

- HDI Technology: Maximum density in minimal space with HDI PCB manufacturing

- Chip-scale Packages: Direct die attachment

- Embedded Components: Integrated within PCB layers

- Wireless Power: Eliminating battery requirements

Hermetic sealing prevents body fluid ingress. Biocompatible encapsulation ensures safety. Telemetry enables remote monitoring. Power management extends operational lifetime.

Intelligent Medical Lighting

Smart features enhance clinical effectiveness:

- Spectral Tuning: Optimizing wavelengths for specific treatments

- Dosimetry Monitoring: Tracking delivered light dose

- Adaptive Control: Adjusting output based on feedback

- Data Logging: Recording treatment parameters

- Network Integration: Connecting to hospital systems

Closed-loop control maintains consistent output. Calibration functions ensure accuracy. User interfaces simplify operation. Cybersecurity protects patient data.

Quality Assurance for Medical LED PCBs

Comprehensive testing ensures medical device safety and effectiveness.

Optical Validation: Photometric and colorimetric testing:

- Spectral power distribution measurement

- Color rendering index verification

- Luminous intensity distribution

- Flicker percentage and frequency

- Photobiological safety per IEC 62471

NIST-traceable calibration ensures accuracy. Multiple measurement points confirm uniformity. Temperature coefficient characterization predicts variations. Aging tests validate long-term stability.

Electrical Safety Testing: Compliance with medical standards:

- Dielectric withstand voltage testing

- Ground bond resistance verification

- Leakage current measurement

- Insulation resistance confirmation

- Patient auxiliary current limits

Production line testing ensures every unit meets requirements. Type testing validates design compliance. Periodic testing confirms continued conformance.

Clinical Validation Support: Evidence supporting medical claims:

- Irradiance mapping for treatment areas

- Spectral analysis for therapeutic wavelengths

- Uniformity documentation for dosimetry

- Stability data supporting treatment duration

- Comparative testing against predicate devices

Test protocols align with clinical requirements. Statistical analysis confirms significance. Documentation supports regulatory submissions.

Partnering for Medical LED Innovation

Medical LED applications demand exceptional quality, regulatory expertise, and reliable manufacturing. Our ISO 13485 certified facility combines medical device experience with LED technology expertise, delivering compliant products that improve patient outcomes. From concept through commercialization, we support medical device manufacturers with comprehensive solutions meeting the highest healthcare standards.

Frequently Asked Questions

Q1: What medical device regulations apply to LED PCBs?

A: IEC 60601 for electrical safety, ISO 13485 for quality systems, ISO 14971 for risk management, and IEC 62471 for photobiological safety.

Q2: Can you support FDA submission requirements?

A: Yes, we provide comprehensive documentation including design history files, device master records, and validation reports supporting 510(k) and PMA submissions.

Q3: What biocompatibility testing is required?

A: ISO 10993 defines testing based on contact type and duration. Common tests include cytotoxicity, sensitization, and irritation.

Q4: How do you ensure long-term reliability for medical devices?

A: Accelerated life testing, highly accelerated stress screening, and real-time aging studies validate reliability exceeding typical 7-10 year medical device lifetimes.

Q5: Can you manufacture LED PCBs for implantable devices?

A: Yes, we support implantable device requirements including hermetic packaging, biocompatible materials, and specialized testing.

Ready for Medical-Grade LED PCBs?

Trust your medical LED projects to experienced manufacturers understanding healthcare's unique requirements. Our commitment to quality, compliance, and innovation ensures your medical devices deliver superior clinical outcomes while meeting all regulatory requirements.