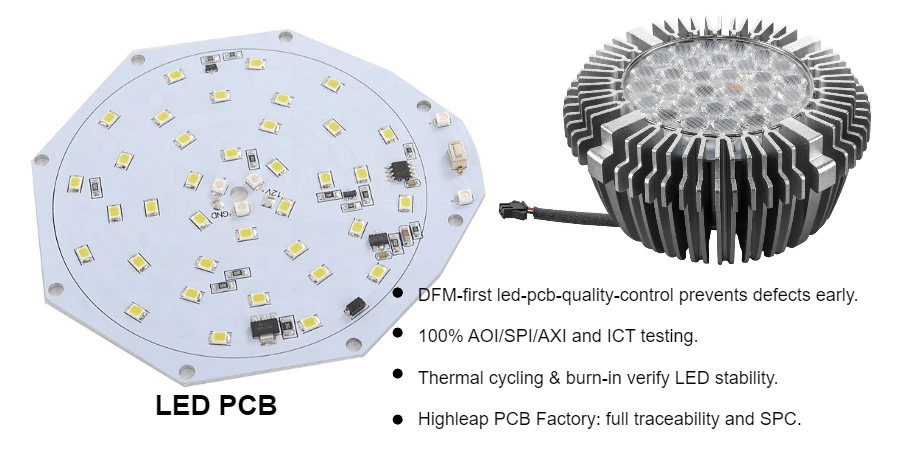

Zero-defect LED PCB manufacturing starts with a closed-loop quality system—not luck. At Highleap PCB Factory (PCB manufacturing + PCB assembly), we control every phase from incoming material verification and pick-and-place calibration to AOI/AXI, ICT, and final optical test, using SPC and full traceability to prevent defects before they ship. Our disciplined led-pcb-manufacturing approach delivers on-spec, repeatable performance with competitive costs and fast lead times—so your lighting launches brighter, lasts longer, and scales with confidence.

Incoming Material Inspection and Verification

Quality begins with validated raw materials meeting strict specifications.

Substrate Material Certification: Every aluminum, ceramic, or FR-4 substrate shipment includes certificates verifying thermal conductivity, dielectric strength, and dimensional tolerances. We perform incoming testing using thermal conductivity meters confirming manufacturer specifications. Our metal core PCBs undergo specialized thermal conductivity verification, while ceramic PCBs receive additional dielectric strength validation. Standard FR4 PCBs used in LED applications require surface quality inspection preventing contamination affecting adhesion.

LED Component Qualification: LED quality directly impacts final product performance:

- Bin code verification ensures color and brightness consistency

- Forward voltage testing confirms electrical specifications

- Thermal resistance measurements validate heat dissipation

- Reliability data review including LM-80 reports

Sample testing from each LED lot verifies specifications before production release. Moisture sensitivity level tracking prevents assembly defects. Counterfeit detection procedures identify non-genuine components.

Chemical and Process Material Control: Solder paste, flux, and cleaning chemicals require careful management:

- Viscosity testing ensures consistent solder paste printing

- Flux activity verification prevents insufficient wetting

- Contamination testing of cleaning chemicals

- Shelf life tracking prevents expired material usage

In-Process Quality Monitoring

Real-time inspection during manufacturing prevents defect propagation.

PCB Fabrication Controls

Each fabrication step includes specific quality checkpoints:

- Post-Lamination: Dielectric thickness measurement ensures thermal performance

- Post-Drilling: Hole quality inspection prevents plating defects

- Post-Plating: Copper thickness verification confirms current capacity

- Post-Etching: Trace width/spacing measurement ensures design compliance

- Post-Solder Mask: Coverage and thickness validation

For high-power LED applications requiring superior heat dissipation, high thermal PCBs undergo additional thermal interface validation. Statistical process control charts track critical parameters. Automatic optical inspection systems detect defects immediately. First article inspection validates new designs before volume production.

Assembly Process Monitoring

SMT assembly quality depends on consistent process execution:

- Solder Paste Inspection: 3D measurement of volume and placement

- Pre-Reflow AOI: Component presence, polarity, and alignment

- Post-Reflow AOI: Solder joint quality and defect detection

- In-Circuit Testing: Electrical functionality verification

Our SMT assembly processes incorporate real-time feedback enabling immediate process adjustments. Traceability systems link quality data to specific boards. Statistical analysis identifies trends before they become problems. For complex LED designs with miniaturized components, HDI PCBs require enhanced inspection protocols ensuring micro-via integrity and fine-pitch component placement accuracy.

Comprehensive Testing Protocols

Multiple test methods validate LED PCB performance and reliability.

Electrical Testing Suite: Beyond basic continuity, comprehensive electrical validation includes:

- Insulation resistance testing between circuits and substrate

- High-potential testing for safety compliance

- Current carrying capacity verification under load

- Impedance testing for high-frequency circuits

- Power cycling to verify thermal/electrical stability

Automated test equipment provides consistent, repeatable measurements. Data logging creates permanent quality records. Pass/fail criteria based on industry standards and customer specifications. Our Gerber viewer tools enable precise pre-production verification, ensuring manufacturing files meet quality standards before production begins.

Thermal Performance Validation: Heat dissipation effectiveness determines LED lifetime:

- Junction temperature measurement using thermal cameras

- Thermal resistance calculation from junction to ambient

- Heat distribution mapping across LED arrays

- Accelerated thermal cycling for reliability prediction

- Thermal shock testing for extreme environment applications

Correlation between thermal simulations and actual measurements validates designs. Long-term thermal stability testing predicts field performance.

Optical Quality Verification: Light output characteristics require specialized measurement:

- Luminous flux using calibrated integrating spheres

- Color temperature and chromaticity coordinates

- Color rendering index for white LEDs

- Beam angle and intensity distribution

- Uniformity across LED arrays

Spectroradiometer measurements ensure accuracy. Photometric data sheets document performance. Batch-to-batch consistency tracking maintains quality.

Environmental and Reliability Testing

Accelerated testing predicts long-term field performance.

Environmental Stress Testing

Simulating harsh conditions reveals potential failures:

- Temperature/Humidity: 85°C/85%RH for 1000+ hours

- Thermal Cycling: -40°C to +125°C repeated cycles

- Salt Spray: ASTM B117 for corrosion resistance

- Vibration/Shock: JEDEC standards for mechanical durability

- UV Exposure: Validates long-term optical stability

Testing follows international standards ensuring global acceptance. Failure analysis of any defects drives continuous improvement. Qualification testing validates new materials and processes.

Burn-In and Life Testing

Extended operation accelerates infant mortality failures:

- Elevated temperature operation for 24-168 hours

- Cycling between on/off states stresses components

- Maximum rated current verifies thermal design

- Light output degradation monitoring

- Driver circuit stability under continuous operation

Statistical sampling plans balance cost with confidence levels. Weibull analysis predicts field failure rates. Warranty data correlation validates test effectiveness.

Statistical Process Control Implementation

Data-driven quality management ensures consistent production.

Control Chart Monitoring: Critical parameters tracked in real-time:

- Solder paste thickness after printing

- Component placement accuracy

- Reflow temperature profiles

- Solder joint quality metrics

- Test parameter measurements

Upper and lower control limits trigger investigations. Process capability indices (Cpk) demonstrate stability. Continuous improvement reduces variation over time.

Defect Analysis and Prevention: Systematic problem-solving eliminates root causes:

- Pareto analysis identifies primary defect types

- Fishbone diagrams explore causation

- 8D problem-solving for customer complaints

- FMEA proactively identifies risks

- Corrective action tracking ensures closure

Cross-functional teams drive improvement initiatives. Supplier quality feedback prevents recurring issues. Best practice sharing across production lines.

Highleap PCB Factory: Your LED PCB Quality Advantage

As Highleap PCB Factory—a PCB manufacturing + PCB assembly electronic factory—we turn quality control into your edge. Our DFM-first engineering, closed-loop SPC, and 100% AOI/SPI/AXI with ICT/functional test lock in consistency from the first panel. Lot-level traceability, controlled materials, and calibrated processes keep color stability, lumen output, and reliability on spec for demanding medical, automotive, and industrial lighting.

We don't just build boards—we industrialize your product. From stack-up selection (MCPCB/Ceramic/HDI) and thermal paths to conformal coating and burn-in, our proven turnkey assembly approach shortens launch cycles, reduces rework, and scales seamlessly from prototype to volume. Partner with us to ship brighter, tougher, and more compliant LED PCBs—faster.

Frequently Asked Questions

Q1: What quality standards do you follow for LED PCBs?

A: We follow IPC-A-600 Class 2/3 for PCB fabrication, IPC-A-610 for assembly, and maintain ISO 9001:2015 certification.

Q2: How do you ensure LED color consistency?

A: LED binning, incoming inspection, and optical testing ensure color temperature remains within specified MacAdam ellipses.

Q3: What documentation comes with each order?

A: Certificate of Conformance, test reports, and any specified quality documentation. Additional data available upon request.

Q4: Can you support automotive quality requirements?

A: Yes, we're IATF 16949 certified and follow APQP/PPAP procedures for automotive LED PCB production.

Q5: How do you handle quality issues?

A: Immediate containment, root cause analysis, corrective action implementation, and preventive measures ensure issues don't recur.

Ready for Zero-Defect LED PCBs?

Partner with quality-focused LED PCB manufacturers. Our systematic approach delivers consistent excellence from prototype through production. Upload your specifications for quality-assured LED PCB manufacturing.