High-reliability lighting, vehicles, and medical systems live or die by the PCB stack—not just the LEDs. Weak thermal paths, noisy power planes, or poor impedance control shorten lifetime, dim output, and drive costly field returns. Choosing the right PCB manufacturing partner is therefore mission-critical.

Highleap PCB Factory is first and foremost a builder of high-frequency / high-speed, complex multilayer PCBs—HDI & rigid-flex, 8–40+ layers, RF/mmWave and high-speed backplanes with controlled impedance, stacked microvias, backdrill, and low-loss laminates. That’s exactly why teams also trust us for LED PCB manufacturing and assembly when lighting modules sit inside demanding systems.

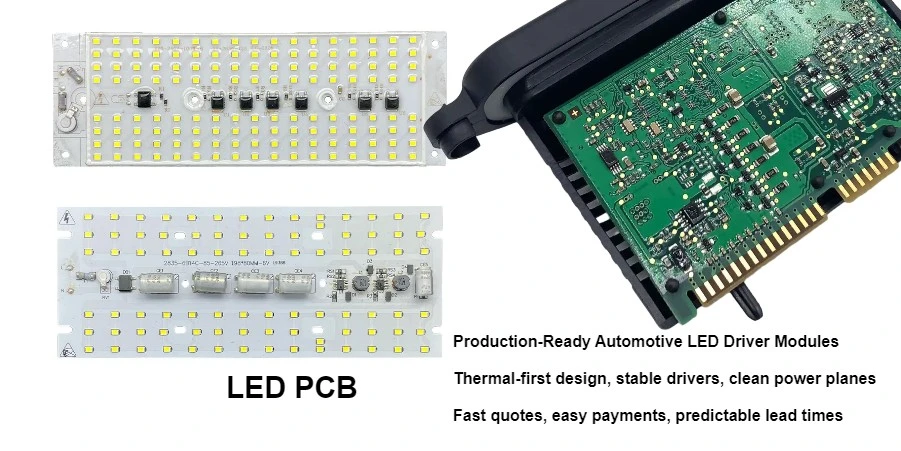

For LED programs, we manufacture aluminum/copper MCPCB, ceramic LED PCBs, and flexible LED PCBs with the same process discipline—thermal-path-first design, void control on thermal pads, bin management, and optical-grade white solder mask—so modules run cooler, brighter, and longer. Expect fast quotes, quick-turn builds, smooth ramp to volume, easy payments (T/T · PayPal · cards), global express shipping, and responsive after-sales that keep your schedule on track.

1. Rapid LED PCB Production with Quality Assurance

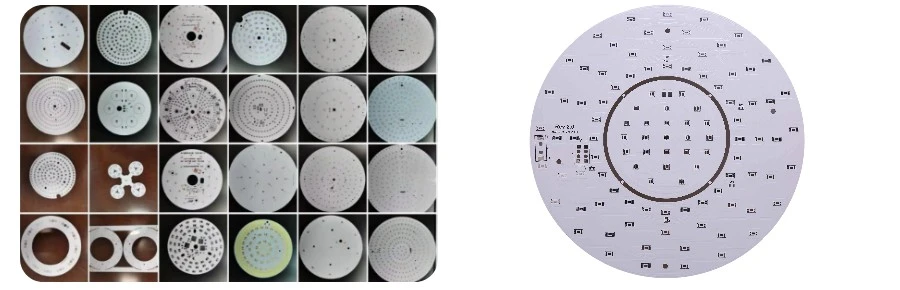

Our LED circuit board manufacturing combines speed with precision. Standard aluminum LED PCBs ship within 24 hours, while complex multi-layer LED boards and ceramic PCBs typically complete in 3-5 days. This quick turnaround doesn't compromise quality—every LED printed board undergoes comprehensive testing including thermal imaging, electrical verification, and optical inspection. We maintain extensive inventory of LED PCB substrates including aluminum base materials (1.0-8.0 W/m·K thermal conductivity), ceramic boards, and copper core PCBs, enabling immediate production starts for your LED lighting boards.

The production flexibility extends from prototype LED PCBs to high-volume manufacturing. No minimum order requirements mean you can validate designs cost-effectively before scaling. Our automated assembly lines handle diverse LED components—SMD LEDs, COB modules, high-power LED arrays—with precision placement ensuring consistent quality across every LED board PCB. Advanced panelization optimizes material usage, reducing costs for volume orders of LED strip PCBs, LED module boards, and custom LED circuit designs. Understanding LED PCB design tips helps optimize your products for manufacturing efficiency.

2. Core Technology: Advanced Thermal Management for LED PCBs

Effective LED PCB heat dissipation determines product lifespan and performance. LED junction temperatures directly impact luminous efficiency, color stability, and operational lifetime. Our engineering approach addresses thermal challenges through multiple strategies, starting with optimal LED PCB materials selection.

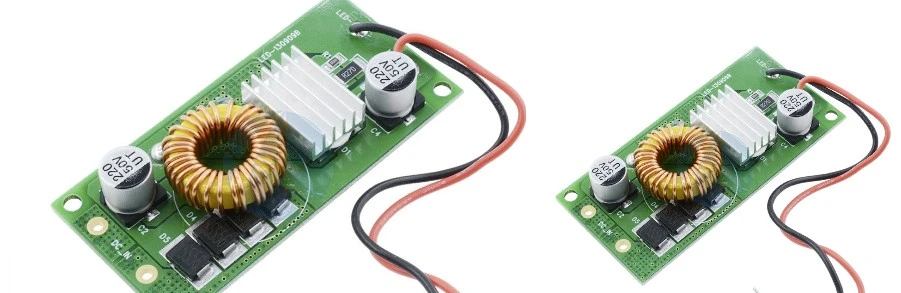

Metal core PCBs (MCPCBs) form the foundation of most LED lighting applications. The aluminum substrate acts as an integrated heat spreader, conducting heat away from LED chips through a thermally conductive dielectric layer. We offer various dielectric options from 1.0 to 5.0 W/m·K, selecting the optimal configuration based on your power density requirements. For extreme applications, ceramic LED PCBs using aluminum nitride achieve thermal conductivity up to 170 W/m·K, enabling direct chip attachment for maximum heat transfer efficiency.

Beyond material selection, our LED PCB manufacturing process incorporates advanced thermal optimization techniques:

- Thermal Via Implementation: Strategic placement of copper-filled vias beneath LED pads creates direct thermal paths to the substrate

- Optimized Copper Distribution: 2oz to 4oz copper weights enhance current carrying capacity and lateral heat spreading

- Embedded Heat Spreaders: Copper coins and vapor chambers for concentrated high-power LED applications

- Surface Treatments: Anodized aluminum backing improves radiation efficiency and environmental protection

These thermal management strategies prove especially critical for demanding LED PCB applications including street lighting, automotive headlights, and industrial illumination where reliability under extreme conditions is paramount.

3. Flexible Payment Terms and Global Shipping

We understand different businesses have varying financial requirements. Established customers benefit from NET 30/60 payment terms, while new accounts can utilize credit cards, wire transfers, or Letters of Credit. Blanket purchase orders and scheduled delivery programs help optimize your inventory management and cash flow. Our accounting team works with international clients to accommodate local payment preferences and currency requirements.

Global logistics partnerships with DHL, FedEx, and UPS ensure reliable worldwide delivery. Standard international shipments reach most destinations within 3-5 business days. Express services deliver to major cities within 24-48 hours for urgent requirements. All LED PCBs ship in moisture-barrier packaging with proper ESD protection. Customs documentation and commercial invoices are professionally prepared to prevent delays. Real-time tracking keeps you informed throughout the shipping process.

4. Complete LED PCB Solutions with Technical Support

Our services extend beyond basic PCB fabrication to encompass complete LED lighting solutions. Free Design for Manufacturing (DFM) review identifies potential issues before production, saving time and preventing costly revisions. Thermal simulation services predict junction temperatures and optimize heat dissipation strategies. Our LED PCB assembly techniques ensure reliable solder joints and consistent LED positioning across arrays.

Component sourcing leverages established relationships with major LED manufacturers including Cree, Osram, Samsung, and Lumileds. Volume purchasing power translates to competitive component pricing for your projects. Turnkey assembly eliminates multi-vendor complexity, providing single-source accountability from bare board through finished LED modules. Our LED PCB testing methods validate both electrical and optical performance parameters.

Specialized expertise in LED PCB for automotive lighting meets IATF 16949 requirements for automotive applications. Medical device manufacturers rely on our ISO 13485 compliant processes for LED PCB for medical devices. Every market segment benefits from our rigorous LED PCB quality control procedures ensuring consistent, reliable performance.

5. Manufacturing Capabilities & Certifications

Built for LED modules—and for complex, high-layer boards. The following capabilities are production-ready and available on standard orders.

Fabrication (PCB)

- Substrates: Aluminum/Copper MCPCB, FR-4, Ceramic (AlN/Al₂O₃), Flex & Rigid-Flex

- Trace/space: 2.5mil/2.5 mil with Laser Direct Imaging

- Copper weight: 1–20 oz standard; heavier copper available for high current/thermal spread

- Thermal dielectrics (MCPCB): 1.0–5.0 W/m·K with tight thickness control

- Drilling: Mechanical & laser microvias; clean breakout on MCPCB/ceramic; backdrill for hybrid driver sections

- Finishes: ENIG, ENEPIG, OSP, Lead-free HASL

- Solder mask (optical grade): White ≥ 88% reflectivity for light engines; black for glare suppression

- Depanelization: V-score, tab-route, laser (for flex) with stress-controlled break-outs

Assembly (SMT & Through-Hole)

- Packages: 0201–large LED, COB/CSP, drivers, connectors, power components

- Reflow: Nitrogen profiles tuned for MCPCB & ceramic high-thermal-mass boards

- Void control: Stencil window-pane apertures + process tuning targeting ≤ 10–15% voids under thermal pads

- Selective solder / hand insert: For mixed technology and heavy terminals

- Optics & bins: LED bin tracking, sample CCT/CRI checks; optional integrating-sphere sampling

Test, Quality & Process Control

- Inline inspection: SPI → AOI → X-ray (thermal pads/BGAs)

- Electrical & functional: 100% flying-probe/ICT, functional tests, optional burn-in

- Electrical design controls: Controlled impedance for driver/control sections; stable power planes to reduce noise/flicker

- Environmental options: Conformal coating / potting (IP65–IP67) and humidity protection

- Traceability: Lot-level materials & process data retained for rapid failure analysis and RMA

Certifications & Compliance

- ISO 9001:2015 quality management system

- UL support for safety-critical applications

- RoHS / REACH compliant materials and processes

- IPC-A-600 Class 2/3 fabrication & IPC-A-610 assembly workmanship

What you get: brighter, cooler LED modules; fewer early failures; predictable lead times from prototype to volume; and documentation that passes customer and regulatory audits.

6. Why Choose Our LED PCB Manufacturing Services

Choosing the right LED PCB manufacturer determines your launch speed, field reliability, and total cost. Highleap PCB Factory blends complex multilayer/high-frequency know-how with LED-specific process control to deliver fast, repeatable results.

- Fast Turnaround: Prototypes in 24–72 h (design-dependent); 3–7 days standard production with true, confirmed lead times

- No Minimum Orders: Single-piece prototyping and smooth ramp to volume using the same process window

- Inventory Programs: Blanket POs, safety stock, and scheduled releases to stabilize your supply chain

- Technical Support: Same-day DFM (stack-up, stencil, thermal vias, panelization) plus driver/EMC checks to hit compliance first time

- Global Shipping: DHL/FedEx/UPS, 3–5 day delivery to most regions; MSL/ESD packaging and full customs paperwork handled

- Payment Flexibility: T/T, PayPal, credit cards, NET 30/60 for approved accounts, multi-currency invoices, L/C for large contracts

- Quality Guarantee: ISO 9001:2015, UL support, RoHS/REACH; 100% electrical test, AOI/X-ray/ICT/functional; 12-month workmanship warranty & DOA replacement

- Turnkey Services: Component sourcing (e.g., Cree/Osram/Samsung), LED bin/CCT/CRI control, programming, conformal coating, and full functional testing

Our teams ship LED PCBs for architectural lighting, automotive, medical, and consumer programs worldwide. You get a dedicated account manager and bilingual engineers, traceable QA reports with every lot, rapid root-cause analysis if issues arise, and a clear rebuild/credit policy when it’s on us—so your schedule and reputation stay intact.

7. Frequently Asked Questions (FAQ)

Q1: What types of LED PCBs can you manufacture?

A: We produce aluminum PCBs, ceramic boards, copper core PCBs, flexible LED strips, and standard FR-4 LED boards for all lighting applications.

Q2: How quickly can you deliver LED PCB prototypes?

A: Standard aluminum LED PCBs ship within 24 hours. Complex designs typically require 3-5 days.

Q3: Do you provide LED assembly services?

A: Yes, complete turnkey assembly including SMD LEDs, COB modules, and through-hole components with full testing.

Q4: What payment terms are available?

A: NET 30/60 for established accounts, credit cards, wire transfers, and Letters of Credit for international orders.

Q5: Can you handle high-volume LED PCB orders?

A: Yes, our production capacity scales from prototypes to millions of units monthly with consistent quality.

Ready to Start Your LED PCB Project?

Get your LED circuit boards manufactured by professionals who understand lighting applications. Fast delivery, superior quality, and comprehensive support ensure your LED products succeed in the marketplace. Contact us today for competitive pricing and expert consultation on your LED PCB requirements.