At Highleap PCB Factory, quality testing is the cornerstone of our comprehensive electronics manufacturing services. While this guide focuses on LED PCB testing methods, our advanced testing capabilities extend to all types of circuit boards we manufacture—from basic FR4 PCB designs to complex high-frequency PCB assemblies. Whether you're producing LED lighting products, RF communication modules, automotive electronics, or medical devices, our state-of-the-art testing facilities ensure every PCB meets exacting quality standards. With complete in-house manufacturing and SMT assembly capabilities, Highleap PCB Factory delivers reliable products across all industries with rigorous validation at every stage.

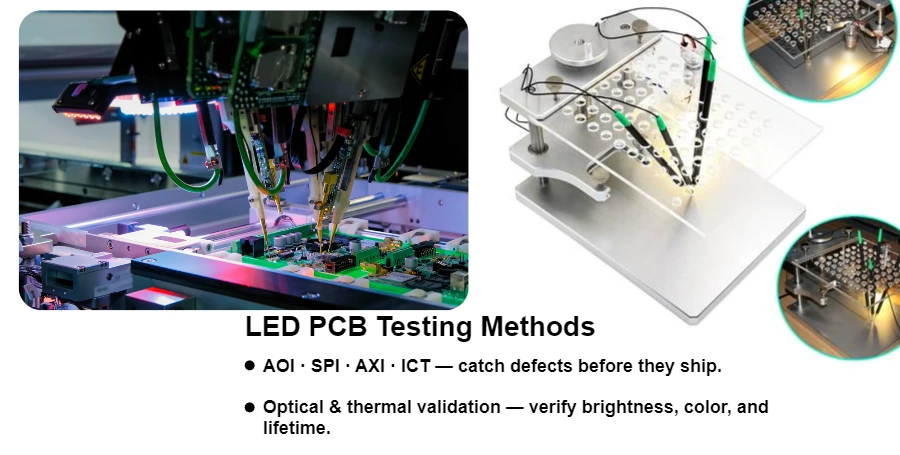

Electrical Testing Protocols for LED Circuit Boards

Electrical validation forms the foundation of LED PCB quality assurance. Every board undergoes comprehensive testing to verify circuit integrity and electrical performance before LED assembly.

In-Circuit Testing (ICT): Our flying probe and bed-of-nails test systems verify component values, check for shorts and opens, and validate circuit continuity. For LED driver circuits, we measure inductance values, capacitor ESR, and switching frequencies to ensure proper operation. Automated test programs developed from your design files achieve 100% node coverage, detecting manufacturing defects that visual inspection might miss.

Functional Testing at Operating Conditions: LED PCBs are tested under actual operating voltages and currents. We verify constant current driver outputs maintain regulation across input voltage ranges. PWM dimming circuits undergo frequency and duty cycle validation. Temperature compensation circuits are tested across -40°C to +85°C to ensure stable LED current despite temperature variations.

High-Potential Testing: Isolation between high-voltage sections and low-voltage control circuits requires verification. Our Hi-pot testing applies up to 3000VAC between isolated sections, ensuring adequate creepage and clearance for safety compliance. This testing is particularly critical for aluminum PCBs and metal-core PCB designs where the dielectric layer provides the only isolation between circuits and the metal substrate. We also perform similar rigorous testing for high-thermal PCB applications requiring exceptional heat dissipation.

Thermal Performance Validation

LED junction temperature directly impacts lifetime and light output. Our thermal testing validates heat dissipation effectiveness across various operating conditions.

Infrared Thermography: FLIR thermal cameras with 0.1°C resolution map temperature distributions across populated LED boards. We identify hot spots, verify thermal via effectiveness, and validate heat spreading patterns. Time-lapse thermal imaging during warm-up reveals thermal equilibrium characteristics and identifies potential reliability issues.

Thermocouple Measurements: For precise junction temperature validation, we install calibrated thermocouples at critical locations. Multi-channel data loggers record temperature profiles during various operating modes. This data validates thermal simulations and ensures junction temperatures remain within specified limits.

Thermal Cycling Tests: Accelerated life testing subjects LED PCBs to repeated temperature cycles from -40°C to +125°C. We monitor for delamination, solder joint failures, and LED degradation. Thermal shock testing with rapid temperature transitions identifies weakness in material interfaces and component attachments.

Optical Measurement and Validation

LED optical performance requires specialized measurement equipment and controlled testing environments to ensure consistent light output and color quality.

Luminous Flux and Efficiency Testing

Integrating sphere measurements provide total luminous flux output and luminous efficacy calculations. Our 2-meter sphere with spectroradiometer measures:

- Total Luminous Flux: Validates light output meets specifications

- Luminous Efficacy: Confirms lm/W efficiency targets

- Color Temperature: Ensures CCT consistency across production batches

- Color Rendering Index: Verifies CRI meets application requirements

Goniometer testing maps light distribution patterns for directional LED modules. Angular intensity measurements validate beam angles and uniformity for specific lighting applications. This testing proves especially important for automotive LED PCBs requiring precise light distribution patterns.

Color Consistency and Binning

LED color consistency across arrays requires careful bin selection and validation. Our optical testing includes:

- Individual LED measurements before assembly

- Post-assembly color uniformity verification

- MacAdam ellipse analysis for color matching

- Spectral power distribution measurements

For RGB and tunable white applications, we validate color mixing accuracy across the full adjustment range. Calibration procedures ensure consistent color reproduction between units.

Reliability and Environmental Testing

Long-term reliability validation ensures LED PCBs maintain performance throughout their operational lifetime.

Highly Accelerated Life Testing (HALT): Combined temperature, humidity, and vibration stress identifies design margins and potential failure modes. Step-stress testing progressively increases stress levels until failure, revealing weak points in the design. This testing accelerates equivalent years of operation into days or weeks.

Salt Spray and Corrosion Testing: For outdoor and marine LED applications, salt fog testing per ASTM B117 validates corrosion resistance. Conformal coating effectiveness is verified through extended exposure to corrosive environments. Edge seal integrity prevents moisture ingress that could compromise aluminum PCB dielectric layers.

Vibration and Mechanical Shock: Automotive and industrial LED applications require resistance to mechanical stress. Random vibration testing simulates transportation and operational vibration. Mechanical shock testing validates solder joint reliability and component attachment strength.

Manufacturing Process Validation

Process control ensures consistent quality across production runs. Our validation protocols monitor critical manufacturing parameters.

Solder Paste Inspection (SPI): 3D solder paste measurement after stencil printing ensures proper volume and placement. Statistical analysis identifies printing trends before they impact quality. For LED thermal pads, we maintain strict control of paste volume to minimize thermal resistance.

Automated Optical Inspection (AOI): Post-placement and post-reflow AOI catches component issues before electrical testing. Machine learning algorithms improve defect detection rates while reducing false calls. Special attention focuses on LED polarity, alignment, and solder joint quality.

X-Ray Inspection: Void analysis in thermal pad solder joints ensures adequate heat transfer. BGA and QFN package inspection verifies hidden solder joint quality. For COB LED applications, die attach coverage and wire bond integrity receive detailed inspection.

Quality Documentation and Traceability

Comprehensive documentation ensures complete traceability and supports customer qualification requirements.

Test Reports and Certificates: Every shipment includes detailed test reports documenting electrical, thermal, and optical measurements. Certificates of conformance verify compliance with specifications. Statistical process control charts demonstrate production consistency.

Failure Analysis Capabilities: When issues arise, our failure analysis laboratory identifies root causes. Cross-sectioning, SEM analysis, and FTIR spectroscopy reveal failure mechanisms. Corrective actions prevent recurrence and improve overall reliability.

Data Management Systems: Electronic records maintain complete production history for every LED PCB. Parametric test data enables trend analysis and predictive quality management. Customer portals provide real-time access to quality documentation. Our BOM viewer tool helps customers verify designs before production, ensuring testing parameters align with design intent.

Frequently Asked Questions

Q1: What testing is required for automotive LED PCBs?

A: Automotive applications require AEC-Q100 qualification including temperature cycling, humidity testing, vibration, and EMC validation per CISPR 25 standards.

Q2: How do you test LED color consistency?

A: We use spectroradiometers to measure chromaticity coordinates, ensuring all LEDs fall within specified MacAdam ellipse tolerances.

Q3: Can you perform custom testing protocols?

A: Yes, we develop custom test fixtures and programs based on your specific requirements, including automated functional testing and burn-in procedures.

Q4: Do you only test LED PCBs?

A: No, Highleap PCB Factory tests all types of PCBs we manufacture—from RF boards to high-speed digital circuits, medical devices to automotive electronics. Our testing capabilities cover the entire spectrum of electronic products.

Q5: How do you ensure testing accuracy?

A: All test equipment undergoes regular calibration traceable to national standards. Gauge R&R studies validate measurement system capability.

Ready to Validate Your LED PCB Design?

Upload your specifications for comprehensive testing solutions. Our LED PCB testing experts ensure your products meet performance and reliability requirements. Contact us today for fast quotes and technical consultation.

Your Complete PCB Manufacturing and Testing Partner

While LED PCB testing is just one facet of our capability, Highleap PCB Factory delivers end-to-end verification for every electronic product we build—power supplies, motor controllers, RF modules, and high-speed digital systems—using the same disciplined methods outlined in our led-pcb-manufacturing workflow. Our ISO 9001:2015, IATF 16949, and ISO 13485 certifications reflect cross-industry quality for automotive, medical, aerospace, industrial, and consumer electronics. We support everything from small batch assembly prototypes to high-volume runs.

Whether you need validation for a handful of prototypes or millions of units, our integrated manufacturing and test facilities ensure consistent quality with full traceability. Choosing Highleap PCB Factory gives you a single partner from design verification through final assembly and testing—simplifying supplier management while upholding the highest standards for every product that leaves our facility.