Got PCBs from previous suppliers that need fixing? Field returns piling up? Prototype boards requiring modifications? Before investing in complete remanufacturing, HILPCB can repair your existing boards—saving time and costs.

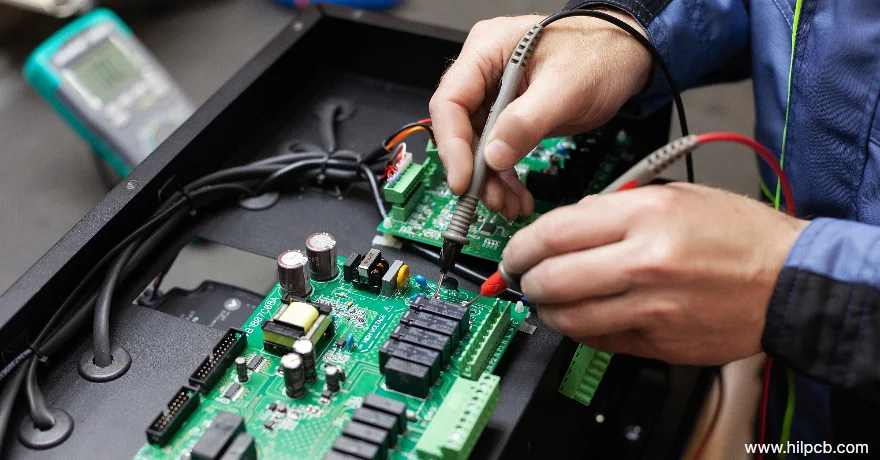

As a PCB manufacturing and assembly factory, we leverage our production equipment and IPC-certified technicians to repair boards from any source. The same expertise we use to manufacture high-quality PCBs helps salvage your valuable assemblies.

Who Needs PCB Repair Services?

Your Existing Inventory Issues

Field returns from customers: Component failures, environmental damage, or handling issues create warranty returns. Instead of scrapping entire assemblies, replace failed components and return boards to service.

Boards from previous suppliers: Inherited PCBs with quality issues from other manufacturers? We fix lifted pads, broken traces, and solder defects—giving these boards a second life.

Old stock requiring updates: Design changes or component obsolescence means existing inventory needs modifications. We implement ECO changes faster than remanufacturing new batches.

Development prototypes: Engineering changes during R&D require board modifications. We modify traces, swap components, and adjust circuits—accelerating your development cycle without waiting for new fabrication.

Common Repairable Defects

Lifted or damaged pads: Reconstruct pads using thermally-bonded copper foil, restore electrical connections with jumper wires. IPC-7721 compliant procedures ensure reliability.

Broken traces: Surface traces repaired with jumper wires; internal layer damage accessed through precision via drilling.

Failed components: Remove and replace ICs, BGAs, capacitors, resistors using hot air rework stations—from 0402 passives to complex packages.

Damaged plated through-holes: Eyelet insertion restores electrical continuity and mechanical strength.

Solder defects: Bridges, cold joints, and insufficient solder corrected using proper reflow techniques.

Solder mask damage: UV-curable LPSM protects exposed copper, preventing oxidation and shorts.

Why Manufacturers Make Better Repair Partners

Unlike dedicated repair shops, we're a full-scale PCB manufacturing facility offering repair as a value-added service:

Production-grade equipment: Your boards get repaired using the same hot air stations, reflow ovens, and X-ray inspection systems we use for manufacturing—not basic repair tools.

IPC-certified assembly technicians: Our team handles BGA rework, micro-component placement, and complex assemblies daily in production. Repair work leverages this expertise.

Process understanding: We know why defects occur and how to prevent them. When repairing your boards, we identify root causes and recommend improvements for future production.

Quality documentation: Full traceability with repair records, photos, and test results—meeting your audit requirements.

Faster turnaround: Existing production infrastructure means no waiting for specialized repair equipment. Most repairs completed in 3-5 business days.

BGA Rework & Complex Package Repair

Advanced packages require precision equipment we use routinely:

- Temperature-controlled removal with thermocouple monitoring

- Professional reballing with matched stencils

- X-ray inspection verifying void-free joints

- Precision placement (±0.05mm alignment tolerance)

- Validated reflow profiles for each package type

Our PCB rework capabilities handle micro-BGAs, flip chips, QFNs, and other advanced packages commonly used in modern designs.

Prototype Modifications & ECO Implementation

Engineering changes during development:

- Component value changes

- IC upgrades or swaps

- Trace cuts and jumper wire routing

- Additional component installation

- Circuit redesigns for validation testing

Time savings: Modifications completed in 2-3 days versus 2+ weeks for new board fabrication and assembly.

Repair Feasibility Assessment

We recommend repair when:

- Board value exceeds repair cost ($200+ assemblies)

- Defects are localized and repairable

- Lead time for new manufacturing is unacceptable

- Small quantities don't justify new production setup

New manufacturing recommended when:

- Extensive damage across multiple areas

- High-volume needs (repair doesn't scale)

- Board design issues requiring layout changes

- Component obsolescence affecting multiple parts

Transparent pricing:

- Component replacement: $25-$50

- Pad reconstruction: $50-$100 per pad

- Trace repair: $40-$80 per trace

- BGA removal/replacement: $150-$300

- Minimum service: $200-$300

Volume discounts available. We'll assess your boards and recommend repair versus remanufacturing honestly.

Quality Standards & Testing

Every repair includes:

✓ IPC-A-610 Class 2/3 visual inspection under magnification

✓ Continuity and isolation testing

✓ Functional testing when specifications provided

✓ X-ray inspection for BGA and hidden joints

✓ Complete documentation with photos and test results

From Repair to Full Manufacturing Partnership

Many customers start by working with us on PCB design iterations, later expanding to complete manufacturing and testing solutions as their production needs grow.

Test us first: Repair services showcase our technical capabilities and quality standards before you commit to larger production orders.

Smooth transition: Once you see our workmanship on repairs, you'll understand what to expect from our PCB assembly and manufacturing services.

Design feedback: While repairing your boards, we often identify design improvements that reduce future defects—valuable insights we incorporate when you move production to us.

Relationship building: Repair projects create working relationships with our engineers and quality team before larger commitments.

Need to salvage existing PCBs or explore manufacturing options? We handle both. Repair services demonstrate our technical depth, while our manufacturing capabilities deliver quality production runs.

Learn more about our PCB manufacturing and assembly services at www.hilpcb.com/en/