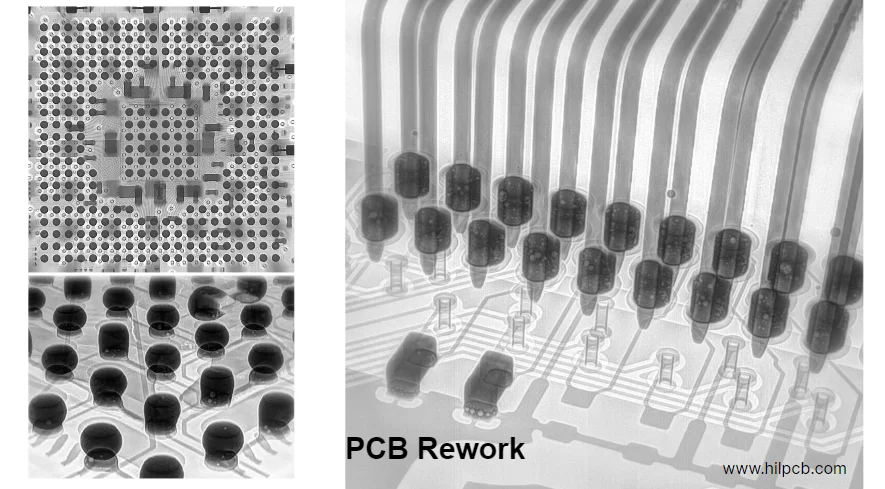

HILPCB provides integrated PCB manufacturing and assembly services with in-house professional rework capability. When assembly corrections become necessary - wrong component placement, BGA void issues, or design changes - our technicians resolve problems immediately without external delays.

This integration delivers clear advantages: our rework team understands board thermal characteristics because we manufactured them. Component replacements happen same-day. Design changes get implemented without vendor coordination. Quality issues stay in-house maintaining your schedule.

Professional rework maintains board integrity and product reliability. Amateur techniques lift pads, damage traces, and create hidden failures. Our IPC-certified technicians and specialized equipment deliver rework matching original assembly standards.

Why Integrated Manufacturing + Assembly + Rework Matters

Split-vendor problems:

- Communication delays coordinating multiple suppliers

- Unclear responsibility when issues arise

- Extended lead times shipping boards for external rework

- Additional costs for shipping and rework services

HILPCB integrated advantage:

Our facility handles PCB manufacturing (2-64 layers), SMT/through-hole assembly, and professional rework under one roof:

- Faster response: Issues corrected immediately, same facility

- Better results: Rework technicians know board construction details from our PCB engineering process

- Clear accountability: Single point of contact for entire project

- Cost efficiency: No external rework charges or shipping delays

BGA Rework: Critical Capability

Modern electronics rely on expensive BGA packages ($5-$50+) mounted on valuable boards ($50-$500). When X-ray inspection reveals voids or components fail, professional BGA rework becomes essential.

Because we manufactured the PCB, our technicians understand thermal characteristics, copper weights, and laminate properties affecting rework. This knowledge prevents pad lifting, board warpage, and adjacent component damage.

Equipment and process:

- Split-vision optics for precision alignment (±0.05mm)

- Temperature profiling with multiple thermocouples

- Board preheating (120-150°C) reduces thermal shock

- Controlled removal following component reflow profile

- X-ray verification of replacement (<15% voids in thermal pads)

Removal procedure:

- Preheat board reducing temperature differential

- Apply localized heat following reflow profile

- Remove package when slight movement indicates full reflow

- Clean pads immediately while solder molten

- Inspect under magnification for damage

Common failures prevented:

- Pad lifting: Precise temperature control, avoid exceeding limits

- Board warpage: Preheat entire board, not just local area

- Adjacent damage: Shield nearby components with heat-resistant materials

Replacement validation:

- Vision-assisted placement (±0.05mm accuracy)

- Package-specific reflow profile

- X-ray inspection verifying joint quality through comprehensive PCB inspection

- Electrical testing before completion

Success rate: >98% first-pass success on BGA rework operations. Visit our PCB repair services for detailed capabilities.

SMT Component Rework

Surface mount components from tiny 0201 resistors through large QFP processors require different rework approaches.

Small passives (0201-1206):

- Hot air or hot tweezers removal

- Temperature 30-50°C above liquidus point

- Heat both pads simultaneously preventing tombstoning

- Inspect under magnification verifying fillet formation

IC packages (SOIC, QFP, QFN):

- Appropriately-sized hot air nozzle

- Temperature profile brings all pins to reflow simultaneously

- Remove when package shifts slightly

- Inspect for bridges, insufficient solder, or pad damage

- Replace with proper pin alignment and even heating

Reflow profile for rework:

- Preheat: 120-150°C over 60-90 seconds

- Soak: 150-180°C for 60-120 seconds (thermal equilibration)

- Reflow peak: 220-250°C for 30-60 seconds

- Cool gradually preventing thermal shock

ECO Implementation

Engineering Change Orders during product development benefit from our integrated facility. Design changes get implemented efficiently without external coordination, supporting rapid PCB development cycles.

Common ECO types:

Component value changes: Simple resistor/capacitor value substitutions completed quickly. Verify correct values preventing errors.

Component type changes: When footprints differ:

- Jumper wires bridging pad spacing differences

- Unused pad removal preventing shorts

- Mechanical fitment verification

Trace modifications:

- Scrape solder mask, cut trace completely

- Verify cut with continuity tester

- Route jumper wires with appropriate gauge

- Apply solder mask repair preventing shorts

- Secure wires with UV adhesive

Firmware updates: Hardware modifications coordinated with programming updates ensuring complete verification through PCB testing.

Quality Standards and Inspection

IPC-A-610 acceptability criteria applies to all rework - same standards as original assembly. Rework receives 100% visual inspection under magnification:

- Solder joint quality (fillet formation, wetting, volume)

- No bridges or shorts to adjacent conductors

- Component placement and orientation correct

- Mechanical stability without looseness

- Cleanliness without excessive flux residue

Electrical verification:

- Continuity testing verifies intended connections

- Isolation testing confirms no unintended shorts

- Functional testing validates circuit operation

- In-circuit testing when available

Documentation: Complete traceability including issue description, components affected, procedures performed, inspection results, test data, technician identification, and photographs. Critical for regulated industries requiring detailed quality records.

Rework vs Rebuild Decision

Our integrated facility enables honest evaluation. Sometimes rework makes sense; sometimes rebuilding proves more economical through PCB replication or PCB copying services.

Rework makes sense:

- Limited quantity affected

- Board value exceeds rework cost significantly

- Schedule critical, replacement lead time unacceptable

- Prototype/validation units where cosmetics less important

Rebuild makes sense:

- Extensive damage requiring multiple repairs

- High-volume production where rework creates bottleneck

- Rework cost approaches replacement cost

Decision points:

Prototypes (5-50 boards):

- Rework: $50-$200/board

- Replacement: $200-$500/board, 2-3 weeks

- Decision: Rework usually economical

Production (100+ boards):

- Rework: $30-$100/board

- Replacement: $20-$100/board, 1-2 weeks

- Decision: Rework economical for <10% defect rate

Our project managers provide honest recommendations based on technical feasibility, cost, and schedule impact.

Integrated Factory Advantage

Investment in complete rework capability supports quality commitment:

Equipment:

- BGA rework stations ($20,000-$50,000)

- X-ray inspection ($80,000-$150,000)

- Vision systems ($15,000-$30,000)

- Temperature profiling equipment

- Specialized tooling and fixtures

Technician expertise:

- IPC certification (A-610, J-STD-001)

- Experience across component types and technologies

- Thermal management understanding

- Continuous education with package evolution

Advantages throughout project:

During manufacturing: Quality control catches issues early, immediate correction before assembly

During assembly: Multiple inspections (SPI, AOI, X-ray) identify issues, in-house correction maintains production flow

During testing: Immediate diagnosis and correction accelerates debug cycles, especially valuable for prototypes

For ECOs: Design changes implemented efficiently with internal coordination

Customer example: 20-board prototype batch revealed BGA void issues during X-ray inspection. External rework would require 7-9 days and $3,000. Our solution: same-day BGA replacement, re-inspection next morning, <2 days total delay, included in project cost.

Complete PCBA Services

PCB Manufacturing:

- 2-64 layer boards, FR-4 to Rogers materials

- Advanced capabilities: blind/buried vias, impedance control

- Full electrical testing

Assembly:

- SMT: 01005 components through fine-pitch BGAs

- Through-hole: wave and selective soldering

- Prototype to production volumes

Quality assurance:

- Solder paste inspection, first article inspection

- AOI, X-ray inspection

- Functional testing per requirements

- Professional rework capability included

Engineering support:

- DFM review, component selection

- Test development, ECO planning

- Failure analysis through PCB reverse engineering

- Corrective action and PCB cloning for legacy support

Conclusion

HILPCB delivers complete PCBA solutions from bare board fabrication through final assembly with professional rework capability:

- Single-source accountability for quality

- Faster turnaround without external coordination

- Professional rework with IPC-certified technicians

- Cost transparency with fair pricing

- Quality commitment backed by in-house capability

Visit www.hilpcb.com/en/ to discuss your PCB manufacturing and assembly requirements.