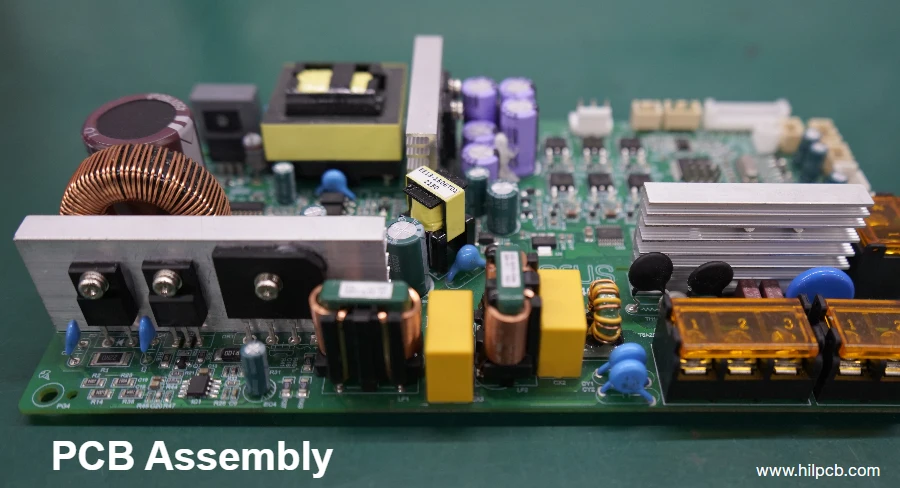

The printed circuit board is designed. Now what? Assembly quality determines whether your product ships on time or becomes a rework nightmare. A single misplaced 0201 resistor in a 5,000-unit production run costs more than the entire PCB order. Solder paste stencil errors create shorts under BGA packages that X-ray cannot catch until field failures spike.

HILPCB specializes in complex assembly: 01005 components for wearables, 0.3mm pitch BGAs for processors, conformal coating for industrial equipment, and ISO 13485 medical device assembly. We handle what matters—getting your boards assembled correctly the first time. Our integrated PCB manufacturing and PCB fabrication capabilities ensure seamless transition from bare boards to assembled products.

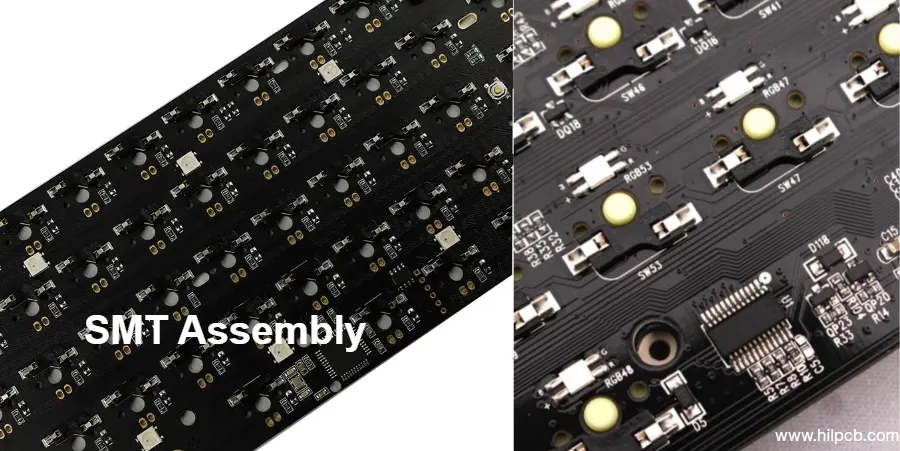

Fine-Pitch SMT Assembly: When Components Shrink

The Miniaturization Race

Smartphone motherboards now pack 3,000+ components into areas smaller than a credit card. Chip packages evolved from 0.5mm pitch QFPs to 0.3mm pitch BGAs. Passive components went from 0402 (1.0×0.5mm) to 01005 (0.4×0.2mm)—barely visible to the naked eye. This evolution demands advanced PCB design considerations for component placement and thermal management.

Fine-Pitch Capability:

- 01005 components (0.4×0.2mm): Smallest passives for ultra-compact designs

- 0201 components (0.6×0.3mm): Standard for smartphones, wearables

- 0.3mm pitch BGAs: Processors, FPGAs, high-density SoCs

- 0.4mm pitch QFNs: Wireless modules, power management ICs

- Package-on-Package (PoP): Stacking DRAM on processor for phones/tablets

Assembly Challenges:

- Solder paste stencils: Laser-cut apertures as small as 0.15mm

- Placement accuracy: ±0.025mm tolerance required

- Reflow profiling: Different thermal mass components on same board

- Inspection: 3D AOI required; 2D cannot verify solder volume

Applications:

- True Wireless Earbuds: Main PCB under 15×8mm with 200+ components

- Smartwatches: Curved rigid-flex boards with 01005 passives

- Medical Wearables: Biocompatible assembly for continuous glucose monitors

- 5G Smartphones: Multi-layer HDI boards with 0.3mm pitch application processors

Our PCB services team can review your design for optimal SMT assembly before production begins.

BGA Assembly & X-Ray Inspection

The Hidden Joint Problem

Ball Grid Array packages hide solder joints under the component body. Visual inspection is impossible. Even 3D AOI cannot see beneath. The only verification: X-ray inspection viewing through the component to examine every solder ball. Working with an experienced PCB company ensures proper BGA handling from design through assembly.

BGA Types We Handle:

- Standard BGA: 0.5-1.0mm pitch, common for memory, controllers

- Fine-Pitch BGA: 0.3-0.4mm pitch for processors, FPGAs

- Micro-BGA (µBGA): <0.5mm pitch for compact devices

- PoP (Package-on-Package): Memory stacked on processor

X-Ray Inspection Criteria:

- Void analysis: <25% void area in individual balls, <15% in thermal pads

- Bridging detection: Adjacent ball shorting

- Insufficient solder: Ball collapse or non-wetting

- Alignment verification: Package centering on pads

BGA Rework Capability: When BGA assembly fails (or customer provides boards for rework):

- X-ray identifies defect location

- Component removal with precision heat control (avoid board damage)

- Pad cleaning and solder ball re-formation if needed

- New component placement with ±0.05mm accuracy

- Reflow with component-specific profile

- Post-rework X-ray verification

Failure Modes We Fix:

- Voids in thermal pads (common on power devices)

- Insufficient solder (incomplete reflow or paste shortage)

- Bridging (solder paste bleeding or ball collapse)

- Component tombstoning or shifting during reflow

Our PCB prototyping service includes assembly design review to prevent BGA issues before production.

Turnkey vs Consignment Assembly: Which Model Fits?

The Procurement Decision

You have two paths: source components yourself (consignment) or let us handle it (turnkey). Neither is universally better—it depends on your business model. As a leading PCB manufacturer, we support both approaches with equal expertise.

Assembly Model Comparison

| Factor | Turnkey (We Source) | Consignment (You Source) |

|---|---|---|

| Timeline | 7-14 days (includes procurement) | 3-5 days (components ready) |

| Cost Structure | Single quote, procurement margin included | Transparent labor cost, you manage BOM cost |

| Component Quality | Authorized distributors, counterfeit prevention | Your responsibility, we inspect incoming |

| Inventory Risk | We hold risk for overages | You manage inventory and excess |

| Best For | Startups, fast projects, no procurement team | Existing inventory, cost control, high volume |

Partial Turnkey (Hybrid Model): We source commodity components (resistors, capacitors, standard ICs) while you provide:

- Proprietary ASICs or programmed microcontrollers

- Long-lead-time components already in your inventory

- Components with specific supplier requirements

- Obsolete or hard-to-find parts

This balances convenience with control. Typical split: we source 80% of BOM lines, you provide 20% critical components.

Component Sourcing Process (Turnkey):

- BOM analysis: Verify availability, flag obsolete parts, suggest alternatives

- Procurement: Authorized distributors only (Arrow, Avnet, Digi-Key, Mouser, TTI)

- Incoming inspection: Visual check, electrical testing for critical components

- MSD handling: Bake moisture-sensitive devices per J-STD-033 before assembly

- Kitting: Organize by assembly batch with full traceability

Our PCB production processes ensure consistent quality whether using turnkey or consignment models.

Application-Specific Assembly Requirements

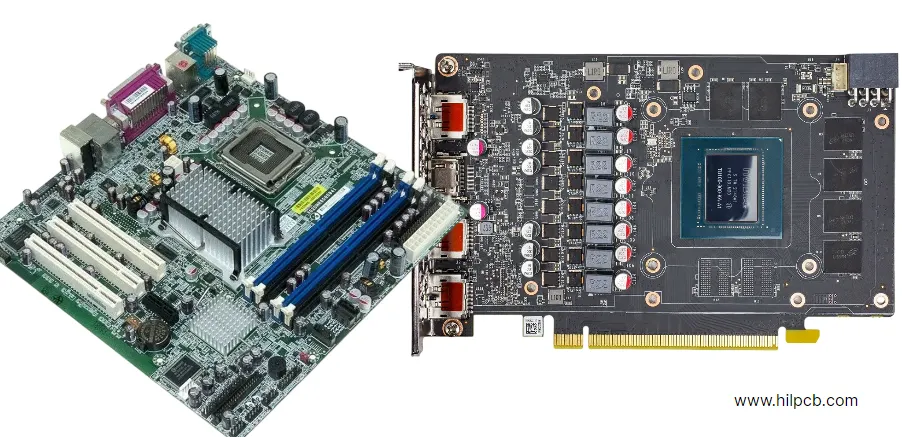

Automotive Assembly (IATF 16949)

Automotive electronics must survive 15+ years, -40°C to +125°C, vibration, thermal cycling, and still meet safety-critical reliability. Standard consumer assembly processes do not suffice. Our PCB factory maintains dedicated automotive production lines with specialized controls.

IATF 16949 Requirements:

- AEC-Q qualified components only

- PPAP (Production Part Approval Process) documentation

- First article inspection with dimensional verification

- Statistical process control (SPC) with Cpk ≥1.67

- 100% traceability: component lots to finished assemblies

Automotive Applications:

- ADAS Systems: Radar boards (77GHz), camera modules, lidar controllers

- Powertrain: Engine control units (ECU), transmission controllers

- EV Power Electronics: Motor inverters (heavy copper PCBs), DC-DC converters, BMS

- Infotainment: Display drivers, connectivity modules

Testing:

- Extended temperature burn-in: -40°C and +125°C cycling

- Vibration testing per AEC-Q200 (board level) or AEC-Q100 (IC level)

- Thermal shock: Rapid temperature transitions

- Hi-Pot isolation testing for high-voltage systems (EV)

Medical Device Assembly (ISO 13485)

Medical devices face FDA/CE mark regulations. Assembly must be documented, traceable, and validated. One contaminated particle in an implantable device can kill a patient. Our comprehensive PCB solutions include cleanroom facilities for medical applications.

ISO 13485 Requirements:

- Design history file (DHF) support

- Cleanroom assembly for implantables (Class 10,000 or better)

- Biocompatible materials: RoHS compliance, halogen-free, specific coatings

- Sterilization compatibility: Autoclave (121°C steam), gamma radiation, or EtO

- IPC Class 3 workmanship: Strictest acceptance criteria

Medical Applications:

- Implantable Devices: Pacemakers, neurostimulators, cochlear implants (hermetic sealing)

- Diagnostic Equipment: Blood glucose monitors, pulse oximeters, ECG machines

- Wearable Health: Continuous glucose monitors (CGM), smart patches

- Surgical Instruments: RF ablation controllers, endoscopic cameras

Conformal Coating for Medical:

- Parylene C: Biocompatible, pinhole-free, vapor-deposited for implants

- Silicone: Flexible, biocompatible for wearables

- Urethane: Chemical resistance for diagnostic equipment exposed to body fluids

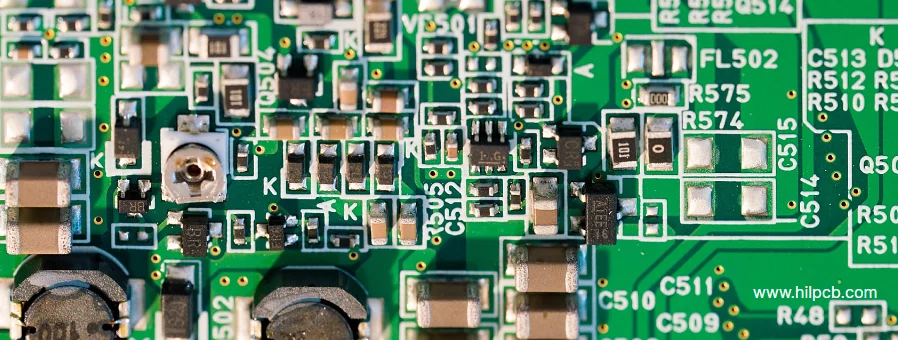

Testing & Quality Control

Multi-Layer Inspection Strategy

Assembly defects cost exponentially more to fix as they progress through production. Finding a solder bridge after reflow: $0.50 rework. Finding it after conformal coating: $5. Finding it in field failure: $500+ (warranty, reputation damage). Our integrated approach to PCB manufacturing includes comprehensive testing at every stage.

Inspection Points:

1. Solder Paste Inspection (SPI) - 3D: Before component placement. Measures paste volume, height, area coverage. Catches stencil printing errors: insufficient paste, bridges, smearing. Typical spec: ±25% volume tolerance.

2. Pre-Reflow AOI: After placement, before oven. Detects: Missing components, wrong parts, polarity errors, shifted components. Fixing at this stage: Just reposition component (no solder yet).

3. Post-Reflow AOI - 3D: After reflow oven. Solder joint quality: Insufficient solder, excess solder, bridging, solder balls. Component presence and orientation verification.

4. X-Ray Inspection: All BGAs, QFNs, and bottom-terminated components. Void analysis in solder joints. Hidden bridging detection. Package alignment verification.

5. Electrical Testing:

- Flying Probe: 100% net connectivity, no fixture required, flexible for prototypes

- ICT (In-Circuit Test): Component-level testing with bed-of-nails fixture (volume production)

- Boundary Scan (JTAG): Tests complex digital ICs without physical access to all nets

- Functional Test: Power-on, I/O verification, programming/calibration

Quick Turn Assembly Timelines

Standard Timelines:

- Consignment (components ready): 3-5 days

- Partial turnkey (we source some): 5-7 days

- Full turnkey (we source all): 7-14 days

24-Hour Express Assembly:

- Simple boards (2-8 layers, <200 components)

- Components in our stock or customer provides

- Standard SMT process (no BGA rework, conformal coating)

- Premium: +50-100% assembly cost

When Express Does Not Work:

- Complex BGA packages requiring profile development

- Conformal coating (requires cure time)

- First article with unknown component reflow behavior

- Programming/calibration requiring custom fixtures

Our PCB prototyping service offers flexible timelines for design validation phases.

Why HILPCB for PCB Assembly

We do not assemble simple LED boards at lowest cost. Our strength: Complex electronics where assembly quality determines product success. As an established PCB company with integrated fabrication and assembly, we control the entire production chain.

Technical Capabilities:

- 01005 component placement (0.4×0.2mm)

- 0.3mm pitch BGA assembly with X-ray inspection

- ISO 13485 medical device assembly (cleanroom available)

- IATF 16949 automotive assembly with PPAP documentation

- Conformal coating: Acrylic, silicone, urethane, Parylene C

Engineering Support:

- Design for Assembly (DFA) review before production

- Component alternative suggestions for availability issues

- Reflow profile optimization for mixed thermal mass

- Test fixture design for functional testing

- Failure analysis and root cause investigation

From 5-board prototypes to 50,000-unit production runs, HILPCB delivers assembly quality that ships without rework. Our complete PCB services portfolio ensures seamless integration from design through delivery.

FAQ

Q: What is the smallest component you can assemble? A: 01005 (0.4×0.2mm) passives and 0.3mm pitch BGAs. Below this, yield drops significantly and cost increases 2-3×.

Q: Do you provide X-ray inspection for all BGAs? A: Yes, standard for all BGA/QFN packages. Void analysis, bridging detection, alignment verification. Reports provided with each batch.

Q: Turnkey vs consignment—which saves money? A: Depends on volume. Turnkey adds 5-15% procurement margin but saves your labor. Consignment gives cost transparency but requires your procurement team. Break-even typically 500-1000 units.

Q: Can you handle automotive (IATF 16949) and medical (ISO 13485)? A: Yes, both certified. Automotive includes PPAP documentation. Medical includes design history file (DHF) support and cleanroom assembly for implantables.

Q: What causes BGA voids and how do you prevent them? A: Voids from moisture in paste, poor reflow profile, or contaminated pads. Prevention: Controlled humidity storage, paste baking if needed, optimized reflow profile with long soak time, nitrogen atmosphere if required. Target: <15% void in thermal pads.