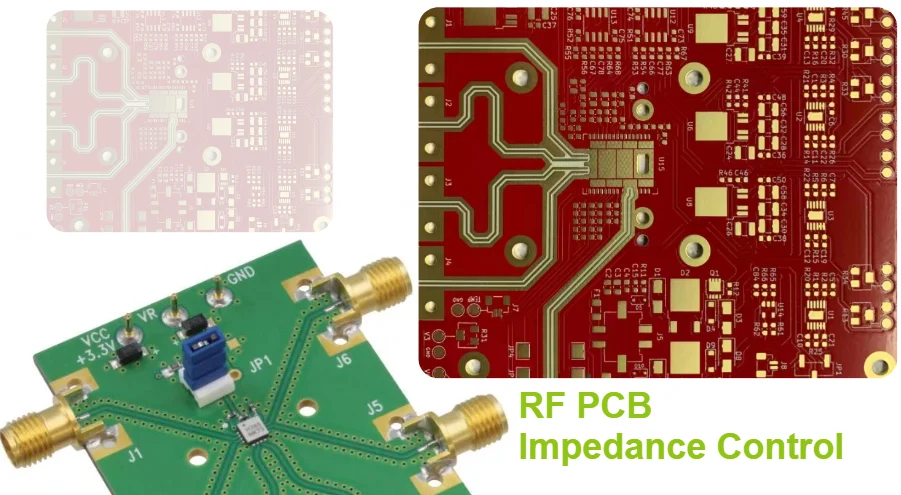

Impedance control represents the difference between RF success and expensive failure. When high-frequency signals encounter impedance mismatches, they reflect back toward the source instead of transferring power to the load. Even small impedance variations can destroy system performance, making precise impedance control absolutely critical.

At Highleap PCB Factory, we've achieved ±3% impedance tolerance on thousands of RF designs by combining advanced simulation, precision manufacturing, and comprehensive testing. This level of control enables reliable operation across frequencies from 100 MHz to 77 GHz.

The Physics of Characteristic Impedance

Characteristic impedance is an intrinsic property of transmission lines determined by their geometry and surrounding materials. Unlike DC resistance, which depends on conductor material and length, characteristic impedance depends only on the cross-sectional geometry and dielectric properties.

The fundamental relationship Z₀ = √(L/C) defines characteristic impedance in terms of inductance per unit length (L) and capacitance per unit length (C). These parameters depend on trace width, dielectric thickness, dielectric constant, and the electromagnetic field distribution around the conductor.

Physical parameters affecting impedance:

- Trace width: Wider traces have lower impedance due to increased capacitance

- Dielectric thickness: Greater separation increases impedance by reducing capacitance

- Dielectric constant: Higher Dk materials reduce impedance by increasing capacitance

- Trace thickness: Minor effect, slightly increases impedance for thicker conductors

This physics explains why impedance control requires precise dimensional control. Small variations in any of these parameters directly affect the impedance, making manufacturing tolerance control essential for consistent RF performance.

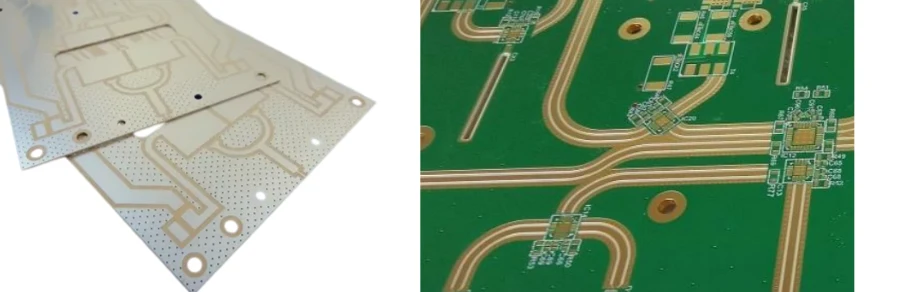

Transmission Line Geometries

Different transmission line geometries offer varying advantages for specific applications and impedance ranges. The choice affects not only electrical performance but also manufacturing cost and reliability.

Microstrip transmission lines place the signal conductor on the PCB surface with a ground plane below. This asymmetric geometry provides impedance ranges from 25-120 ohms while allowing easy component mounting and test access. The exposed conductor makes microstrip susceptible to environmental effects but enables straightforward troubleshooting.

Stripline geometries sandwich the signal conductor between two ground planes, creating a symmetric field distribution. This configuration provides excellent isolation and stable impedance characteristics while eliminating radiation losses. Stripline works well for impedances from 30-100 ohms but requires more PCB layers and limits component access.

Coplanar waveguide structures place ground planes adjacent to the signal conductor on the same layer. This geometry excels at millimeter-wave frequencies and provides excellent probe access for testing, but consumes more board real estate than other approaches.

Differential pairs use two coupled conductors to carry balanced signals. The differential impedance typically ranges from 80-120 ohms while providing excellent noise immunity and reduced electromagnetic emissions.

Each geometry has optimal frequency ranges and applications. Microstrip dominates general-purpose RF applications, stripline serves high-isolation requirements, coplanar waveguide enables millimeter-wave circuits, and differential pairs handle high-speed digital and balanced RF signals.

Manufacturing Process Control

Critical Manufacturing Parameters

Dimensional Control

- Trace width: ±0.025mm

- Dielectric thickness: ±0.025mm

- Layer registration: ±0.025mm

Process Control

- Etch uniformity: ±5%

- Copper thickness: ±10%

- Press parameters: ±2%

Achieving ±3% impedance tolerance requires exceptional manufacturing process control. Every step from material handling through final test must operate within tight specifications to ensure consistent electrical performance.

Trace width control starts with precise imaging and etching. Photolithography systems must maintain registration accuracy while the etching process controls sidewall profiles and width uniformity. Even small variations in developer concentration or etch time can affect trace geometry.

Dielectric thickness control requires careful material handling and lamination processes. Core and prepreg materials must be stored under controlled conditions to prevent moisture absorption. Lamination parameters including temperature, pressure, and time must be precisely controlled to achieve target thickness.

Layer registration accuracy ensures that vias properly connect between layers and that controlled impedance traces maintain their reference relationships. Modern registration systems achieve ±0.025mm accuracy, but this requires regular calibration and maintenance.

Copper surface treatment affects high-frequency performance through skin effect losses. Smooth copper surfaces minimize additional losses compared to rough surfaces that increase the effective surface area and resistance.

Statistical process control monitors these parameters continuously, identifying trends before they cause impedance variations outside specification limits.

Advanced Testing Methods & Design Optimization

Impedance control requires both precise testing and efficient design optimization to achieve the best performance and cost-efficiency.

Advanced Testing Methods

TDR (Time Domain Reflectometry) provides quick, intuitive impedance measurements by analyzing reflected pulses along transmission lines, helping pinpoint problem areas. VNA (Vector Network Analyzer) measures impedance across frequencies, revealing behavior at high frequencies. Automated production testing systems ensure quick, precise impedance verification without wasting valuable PCB space.

Design Optimization Strategies

Effective impedance control comes from understanding material properties, geometric modeling, and design margins. Accurate simulation predicts impedance, while design margins account for manufacturing variations. Via optimization and careful layout techniques minimize parasitic effects and ensure consistent impedance, balancing performance with manufacturing costs.

Troubleshooting Impedance Problems

Impedance control issues can manifest in different ways, from obvious performance degradation to subtle system instabilities that may only surface under specific conditions. To effectively identify and resolve these challenges, a systematic troubleshooting approach is essential.

Common impedance problems often arise from manufacturing variations that exceed design tolerances, errors in stack-up calculations, deviations in material properties, and environmental impacts on electrical performance. Diagnostic techniques, such as TDR and VNA measurements, help pinpoint issues by revealing physical discontinuities and frequency-dependent behaviors. Cross-sectional analysis also plays a crucial role in ensuring that trace dimensions match the design specifications.

The key to addressing impedance problems lies in implementing targeted corrective actions based on root causes. These may include adjusting manufacturing processes, modifying designs, or changing materials. However, prevention is always more cost-effective than correction, and we emphasize proactive strategies like robust design practices, thorough process validation, and continuous monitoring to ensure your RF systems perform optimally while staying within budget and schedule.

Master Impedance Control

Achieve ±3% impedance tolerance with proven design and manufacturing techniques

Get Impedance Control QuoteRelated Technologies: RF PCB Materials | RF PCB Assembly | Microwave PCB