The electronics industry has transformed with the shift from simple DC circuits to complex high-frequency systems that demand precise characteristic impedance control. Central to every modern high-speed design is the characteristic impedance PCB—a precisely engineered circuit board that manages signal transmission across frequencies from DC to millimeter-wave ranges. From 50-ohm RF systems requiring extreme precision to 100-ohm differential pairs managing gigabit data rates, today's characteristic impedance PCB designs represent the foundation of reliable electronic communication.

We provide specialized PCB fabrication and assembly solutions tailored for the unique challenges of impedance-controlled manufacturing, integrating advanced materials, precision processes, and comprehensive testing. From standard 50-ohm single-ended designs to custom impedance values for specialized applications, our manufacturing processes support the demanding accuracy and reliability requirements of global electronics brands and emerging technology companies.

Characteristic Impedance PCB Structure and Design Fundamentals

A typical characteristic impedance PCB must manage electromagnetic wave propagation while maintaining precise impedance values across varying frequencies and environmental conditions. The core architecture for impedance-controlled PCB includes:

- Precise trace geometry calculations for target impedance values (25Ω to 600Ω range)

- Controlled dielectric thickness and material selection for stable performance

- Reference plane management for consistent electromagnetic environment

- Via transition optimization to maintain impedance continuity

- Layer stackup design optimized for specific impedance requirements

- Environmental compensation for temperature and humidity stability

Characteristic impedance PCB designs typically employ multilayer PCB structures with carefully optimized stackups. The challenge lies in achieving target impedance while managing crosstalk, EMI, and signal integrity across diverse frequency ranges. Advanced designs integrate rigid-flex PCB sections for mechanical flexibility while maintaining impedance control through bend regions.

High-frequency applications require specialized attention to conductor surface roughness, dielectric loss tangent, and frequency-dependent effects that can cause impedance variation across the operating bandwidth.

Specialized Manufacturing for Precision Impedance Control

Our production capabilities are specifically optimized for the demanding requirements of characteristic impedance PCB manufacturing across all standard and custom impedance values:

- 50-Ohm Systems: High-frequency PCB materials and precision processes for RF/microwave applications

- 75-Ohm Applications: Optimized stackups for video and cable transmission systems

- 100-Ohm Differential: Advanced coupling control for high-speed digital interfaces

- Custom Impedance Values: Specialized designs for unique system requirements (25-600Ω range)

- Mixed Impedance Designs: Multiple impedance values on single PCB with controlled transitions

- High-Frequency Control: Millimeter-wave capable processes up to 100+ GHz

Manufacturing processes utilize state-of-the-art lithography for ±0.5 mil trace width control, controlled lamination for ±5% dielectric thickness accuracy, and precision copper plating for consistent conductor cross-sections. Our turnkey assembly services include impedance verification, comprehensive testing, and signal integrity validation.

Signal Integrity and Performance Optimization Strategies

Designing characteristic impedance PCBs requires balancing multiple performance factors including signal integrity, power efficiency, and electromagnetic compatibility. Effective impedance control is critical—not only for maintaining signal quality, but also for ensuring system reliability, EMI compliance, and long-term performance stability.

Performance Optimization by Application Type

- RF and Microwave Systems Focus on ultra-low loss materials and precision impedance control to minimize insertion loss and maximize power transfer efficiency.

- High-Speed Digital Interfaces Implements controlled skew and tight impedance tolerance to maintain timing margins and data integrity in multi-gigabit systems.

- Precision Measurement Systems Requires exceptional impedance accuracy and temperature stability to maintain measurement precision across environmental conditions.

- Automotive Electronics Must support harsh environment operation with impedance stability across temperature, humidity, and mechanical stress.

- Telecommunications Infrastructure Prioritizes long-term reliability and performance consistency across wide frequency ranges and power levels.

Material Selection and Environmental Considerations

- Standard FR4 PCB Supports impedance control for applications up to 1-2 GHz with cost-effective materials and proven reliability.

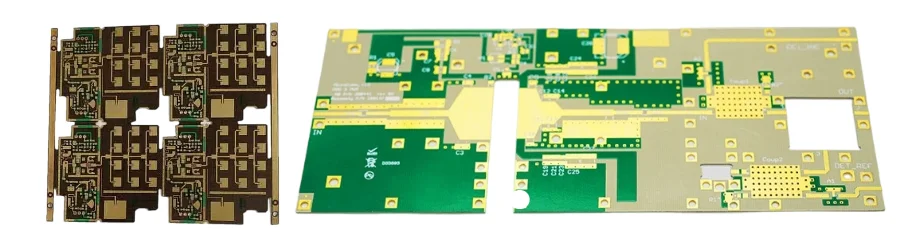

- Advanced Substrate Materials For applications above 5 GHz, Teflon PCB and ceramic PCB materials provide ultra-low loss and exceptional frequency stability.

- Environmental Stability Characteristic impedance PCB designs must prevent impedance drift across operating conditions. This is managed through material selection, thermal compensation, and environmental stress testing.

- High thermal PCB Integration Enables efficient thermal management without compromising impedance control, critical for high-power RF applications and dense digital systems.

Characteristic Impedance PCB Applications and Market Segments

Characteristic impedance PCB technology serves diverse market segments, each with specific technical requirements:

- RF and Microwave Systems for Communication Infrastructure and Test Equipment

- High-Speed Computing with Multi-Gigabit Processor and Memory Interfaces

- Automotive Electronics including Radar, LiDAR, and Advanced Driver Assistance

- Telecommunications Infrastructure for 5G Base Stations and Optical Networks

- Aerospace and Defense with Mission-Critical Radar and Communication Systems

- Medical Electronics for Precision Imaging and Diagnostic Equipment

- Test and Measurement requiring Ultimate Accuracy and Stability

Advanced applications increasingly require mixed-impedance designs with multiple controlled impedance values on single PCBs. Our HDI PCB capabilities enable complex routing while maintaining precise impedance control across all signal types.

Integrated Testing and Validation Solutions

Beyond core characteristic impedance PCB manufacturing, we provide comprehensive validation and testing services:

Impedance Verification:

- Time Domain Reflectometry (TDR) for impedance uniformity along trace length

- Vector Network Analysis (VNA) for frequency-dependent characterization

- Statistical process control for production consistency

- Custom test fixtures for application-specific validation

Advanced Characterization Services:

- S-parameter measurement up to 40 GHz frequency range

- Temperature coefficient analysis for environmental stability

- Eye diagram and signal integrity analysis for digital applications

- EMI pre-compliance testing and optimization

Quality Documentation:

- Comprehensive test reports with statistical analysis

- Certificate of compliance for industry standards

- Design optimization recommendations

- Production capability studies and process validation

Why Choose HILPCB for Characteristic Impedance PCB Manufacturing

The modern electronics market demands exceptional precision, reliability, and cost efficiency in characteristic impedance control. HILPCB combines advanced manufacturing technology with deep expertise in high-frequency design and precision assembly to support brands delivering cutting-edge electronic products.

We are ISO 9001:2015 and IPC-A-610 Class 3 certified, with specialized capabilities in controlled impedance manufacturing and comprehensive testing. Our engineering teams provide electromagnetic simulation, stackup optimization, and signal integrity analysis specifically for characteristic impedance applications. From prototype development to high-volume production, we ensure reliable delivery with focus on impedance accuracy, signal integrity, and manufacturing yield optimization.

Frequently Asked Questions — Characteristic Impedance PCB

Q1: What impedance values can be achieved in PCB manufacturing?

A: We can manufacture PCBs with characteristic impedance values from 25 ohms to 600 ohms, including all standard values (50Ω, 75Ω, 90Ω, 100Ω) and custom impedances. The specific range depends on stackup design, materials, and frequency requirements.

Q2: What tolerance can be achieved for characteristic impedance control?

A: Standard tolerance is ±10% for most applications. Critical high-speed and RF applications can achieve ±5% or ±3% tolerance using controlled dielectric materials and enhanced process controls.

Q3: How does frequency affect characteristic impedance in PCB traces?

A: At low frequencies, impedance is determined by trace geometry and dielectric properties. At high frequencies, dispersion effects, conductor losses, and dielectric losses can cause impedance to vary with frequency, requiring careful material selection.

Q4: Can multiple impedance values be used on the same PCB?

A: Yes, mixed-impedance designs are common. Different circuits can have different impedance requirements on the same board. Careful design ensures proper impedance transitions and isolation between different impedance domains.

Q5: What materials are best for high-frequency characteristic impedance applications?

A: For frequencies above 1 GHz, low-loss materials like Rogers laminates, PTFE-based substrates, or ceramic materials provide optimal performance. Material choice depends on frequency range, loss requirements, and environmental conditions.

Q6: How important is via design for maintaining characteristic impedance?

A: Via design is critical for impedance continuity. Proper via diameter, anti-pad clearance, and back-drilling techniques ensure minimal impedance discontinuity through layer transitions. Advanced HDI vias provide superior high-frequency performance.