Modern unmanned aerial vehicles demand sophisticated electronic systems that balance performance, weight, and power efficiency. Professional drone PCB solutions must integrate complex flight control algorithms, sensor fusion capabilities, and wireless communication systems within extremely constrained form factors. HILPCB specializes in manufacturing high-performance drone circuit boards that enable autonomous flight operations, extended mission durations, and reliable data transmission for commercial, industrial, and recreational UAV applications.

Drone PCB Technology and Flight Control Architecture

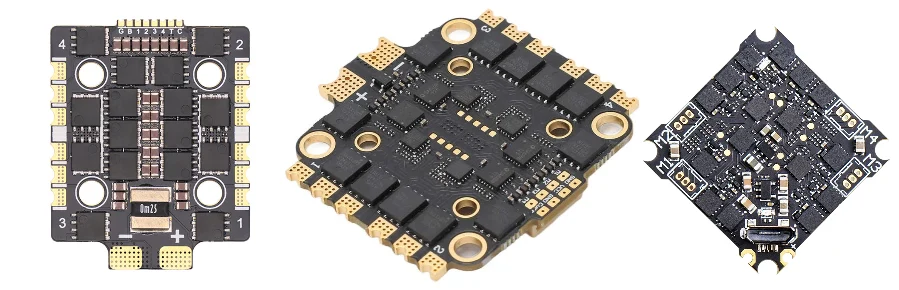

Drone PCB systems serve as the central nervous system for unmanned aerial vehicles, integrating flight control processors, sensor interfaces, communication modules, and power management circuits. Modern quadcopter PCB designs must process real-time data from multiple sensors including accelerometers, gyroscopes, magnetometers, and barometric pressure sensors to maintain stable flight operations.

Essential Drone PCB Components:

- Flight Control Unit: 32-bit ARM Cortex processors running advanced flight algorithms at frequencies up to 168 MHz for real-time control loop execution

- Sensor Interface Circuits: Multi-channel ADCs and digital interfaces supporting IMU sensors, GPS modules, and environmental monitoring systems

- Communication Systems: 2.4 GHz and 5.8 GHz RF transceivers enabling telemetry, video transmission, and remote control functionality

- Power Management: Efficient switching regulators and battery monitoring circuits optimized for lithium polymer battery systems

The fundamental challenge in drone circuit board design involves achieving maximum functionality while minimizing weight and power consumption. Each gram of PCB weight directly impacts flight time and payload capacity, requiring innovative design approaches that prioritize component density and thermal efficiency.

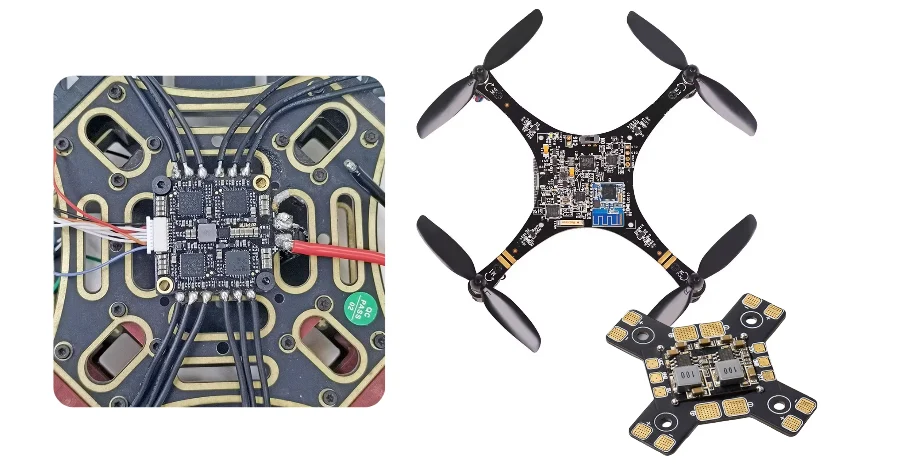

Our flexible PCB technology enables creative form factor solutions, allowing drone manufacturers to integrate electronics seamlessly into aerodynamic airframe designs while maintaining excellent electrical performance and mechanical reliability.

Miniaturization and Weight Optimization Strategies

Successful drone PCB design requires aggressive miniaturization without compromising functionality or reliability. Weight optimization strategies must consider every aspect of the circuit board design, from component selection to substrate materials and assembly techniques.

Advanced Miniaturization Techniques:

- High-Density Interconnect Technology: HDI PCBs with microvias enabling component placement on both sides with minimal layer count

- Embedded Component Integration: Passive components embedded within PCB substrates to reduce surface area requirements

- System-in-Package Solutions: Multi-die modules combining processors, memory, and RF circuits in single packages

- Flexible-Rigid Hybrid Designs: Strategic use of flexible connections to eliminate bulky connectors and cables

Material Selection for Weight Reduction: Modern UAV PCB manufacturing utilizes specialized materials that provide excellent electrical properties while minimizing weight. Ultra-thin copper foils, lightweight core materials, and advanced solder mask technologies contribute to overall weight reduction without sacrificing performance or durability.

Component selection plays a crucial role in achieving optimal weight-to-performance ratios. System-on-chip solutions integrate multiple functions into single packages, reducing both weight and power consumption while improving overall system reliability through reduced interconnections.

Our high-frequency PCB expertise ensures optimal performance for drone communication systems, supporting both control link reliability and high-definition video transmission requirements.

Power Management and Battery Life Optimization

Drone PCB designs must prioritize power efficiency to maximize flight times and operational capabilities. Effective power management systems extend mission durations while maintaining consistent performance across varying flight conditions and payload requirements.

Power Efficiency Design Principles:

- Multi-Rail Power Distribution: Optimized voltage regulation for different subsystems including processors, sensors, and communication modules

- Dynamic Power Scaling: Intelligent power management that adjusts consumption based on flight modes and operational requirements

- Battery Monitoring Systems: Precision voltage and current measurement circuits enabling accurate state-of-charge estimation and cell balancing

- Sleep Mode Implementation: Low-power standby modes for non-critical systems during extended loiter operations

Thermal Management Considerations: Efficient thermal design prevents overheating while maintaining optimal electronic performance. Strategic component placement, thermal vias, and heat spreading techniques ensure reliable operation across environmental temperature ranges from -40°C to +85°C.

Power management circuits must handle the dynamic current demands of drone systems, from high-current motor control during aggressive maneuvers to low-power telemetry transmission during cruise flight. Advanced switching regulators with high efficiency ratings minimize power losses while providing clean, stable voltages for sensitive sensor and communication circuits.

Our multilayer PCB construction techniques enable complex power distribution networks that minimize voltage drops and electromagnetic interference while maintaining compact form factors.

Communication Reliability and Quality Assurance in Flight-Critical PCBs

In aerospace and defense applications, secure communication and proven reliability are non-negotiable. PCB designs must ensure stable data links for guidance, telemetry, or payload control—while withstanding thermal, mechanical, and electromagnetic stress.

Our high-frequency PCBs support dual-band RF transmission (e.g., 2.4 GHz and 5.8 GHz), integrated antenna systems, and encrypted protocols to maintain connectivity in complex environments. Through optimized layouts and EMI shielding, we minimize interference and signal loss.

To ensure mission success, every PCB undergoes comprehensive quality testing, including thermal cycling, vibration simulation, EMI/EMC verification, and full electrical inspection. All processes follow AS9100 and IPC Class 3 standards, with traceable QA protocols from prototype to high-volume production.

Whether for a missile guidance unit or an autonomous UAV, our PCBs are engineered for both communication integrity and long-term operational reliability in critical systems.

Why Choose HILPCB for Drone PCB Manufacturing

HILPCB combines extensive experience in aerospace electronics with innovative manufacturing capabilities specifically tailored for drone and UAV applications. Our comprehensive approach addresses the unique challenges of drone PCB design while delivering cost-effective solutions for commercial and industrial markets.

Specialized Drone Electronics Capabilities:

- Design Optimization Services: Application engineering support for weight reduction, power efficiency, and EMI mitigation

- Rapid Prototyping: Quick-turn PCB fabrication enabling fast design iterations and time-to-market acceleration

- Scalable Manufacturing: Production capabilities spanning prototype quantities through high-volume commercial production

- Supply Chain Management: Component sourcing and obsolescence management for long-term product lifecycle support

Our manufacturing facility integrates advanced inspection technologies including Automated Optical Inspection, X-ray imaging, and in-circuit testing to ensure every drone circuit board meets stringent quality requirements. Environmental testing capabilities validate performance across operational temperature ranges and stress conditions.

Technical Support and Engineering Services: We provide comprehensive design support including electromagnetic compatibility analysis, thermal simulation, and mechanical integration guidance. Our engineering team collaborates with drone manufacturers to optimize PCB designs for specific mission requirements while maintaining manufacturing efficiency and cost targets.

Turnkey assembly services streamline the production process by managing component procurement, assembly scheduling, and quality verification under single-source responsibility, reducing complexity and accelerating development timelines.

Ready to elevate your drone project with professional-grade PCB solutions? Our experienced engineering team is prepared to support your UAV development requirements.

Drone PCB Design and Manufacturing FAQ

What are the key design considerations for drone PCB weight optimization?

Drone PCB weight optimization requires HDI technology, embedded components, lightweight materials, and strategic use of flexible circuits. Every design decision must balance functionality against weight impact, with typical targets of less than 10 grams for flight control boards in recreational drones.

How do power management requirements differ for drone applications?

Drone power management must handle dynamic current loads from motor controllers while maximizing battery efficiency. Key requirements include multi-rail regulation, battery monitoring, thermal management, and intelligent power scaling based on flight modes and operational demands.

What communication frequencies are commonly used in drone systems?

Drone systems typically use 2.4 GHz for control links, 5.8 GHz for video transmission, and various frequencies for telemetry including 433 MHz, 915 MHz, and LoRa bands. Design must ensure minimal interference between multiple communication systems operating simultaneously.

How does environmental testing validate drone PCB reliability?

Environmental testing includes temperature cycling from -40°C to +85°C, vibration testing up to 20G acceleration, humidity exposure, and altitude simulation. These tests validate performance under real-world flight conditions and identify potential failure modes.

What are the typical lead times for drone PCB manufacturing?

Lead times vary by complexity and volume, ranging from 5-7 days for simple prototypes to 2-3 weeks for complex multilayer boards with specialized materials. High-volume production typically requires 3-4 weeks including comprehensive testing and quality verification.

Can HILPCB support both commercial and hobbyist drone projects?

Yes, our capabilities span from prototype quantities for hobbyist projects through high-volume production for commercial drone manufacturers. We provide scalable solutions with appropriate quality levels and cost structures for different market segments and application requirements.