From basic vibrating toothbrushes to advanced AI-powered oral care systems and wireless charging sonic toothbrushes, every modern electric dental device depends on precisely engineered circuit boards optimized for daily oral hygiene use. At HILPCB, we go beyond manufacturing Electric Toothbrush PCBs—we deliver complete electronic solutions including motor control boards, charging station circuits, smart sensor modules, and full turnkey assembly.

Our capabilities integrate ultra-efficient power management, precise motor control, wireless connectivity, and waterproof design principles into compact, user-friendly devices. Whether you are developing a premium sonic toothbrush, an IoT-enabled oral health monitor, or a consumer rechargeable dental care device, we provide the manufacturing precision, engineering expertise, and regulatory compliance to bring your innovation to market successfully.

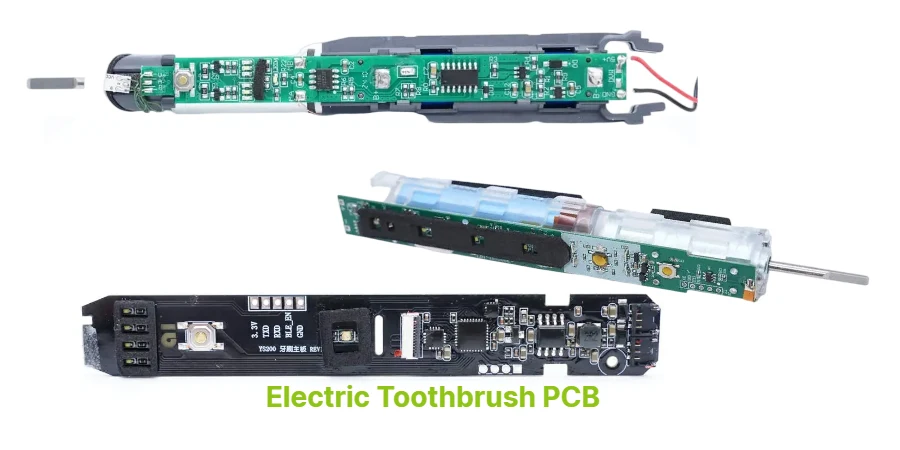

Electric Toothbrush PCB Architecture and Smart Oral Care Integration

A modern Electric Toothbrush PCB must integrate motor control systems, battery management, user interface elements, and smart connectivity features while maintaining strict waterproof requirements and extended battery life. The core architecture for Sonic Toothbrush PCB applications includes:

- Ultra-efficient motor control circuits for sonic and ultrasonic vibration frequencies up to 62,000 movements per minute

- Advanced battery management systems for Smart Toothbrush PCB lithium-ion and NiMH rechargeable cell optimization

- Precision timing circuits for Oral Care PCB two-minute brushing cycles and quadrant interval alerts

- Rechargeable Toothbrush PCB specific: wireless charging coils, inductive power transfer, and charging station communication

- Pressure sensor integration for Dental Device PCB user safety and optimal brushing force monitoring

- Bluetooth Low Energy (BLE) and WiFi connectivity modules for app-based oral health tracking

- Multi-mode brushing pattern control for sensitive teeth, whitening, and gum care applications

- Waterproof sealed design with IPX7 rating for bathroom safety and durability

Professional Smart Toothbrush PCB designs typically employ 4-6 layer multilayer PCB structures to accommodate complex signal routing between motor controllers, sensors, wireless modules, and power management systems while maintaining compact form factors suitable for handheld devices. The challenge of Oral Care PCB design lies in achieving optimal power efficiency for extended battery life while supporting high-frequency motor operation and smart features, requiring specialized FR4 PCB materials with enhanced moisture resistance and long-term reliability.

Dental Device PCB systems increasingly integrate AI-powered brushing analysis and personalized oral health recommendations, enabling real-time feedback and habit improvement in compact, ergonomic designs utilizing HDI PCB technology for maximum component integration density.

Advanced Manufacturing for Personal Care Electronics

Our production capabilities are specifically optimized for the demanding requirements of Electric Toothbrush PCB and Sonic Toothbrush PCB manufacturing:

- Smart Toothbrush PCB: Ultra-low power consumption designs using advanced power management ICs and efficient switching regulators

- Oral Care PCB: Waterproof assembly techniques with conformal coating and sealed connector solutions

- Rechargeable Toothbrush PCB: Precision motor control circuits optimized for sonic frequencies and variable intensity settings using single-double-layer PCB configurations for cost-effective basic models

- Dental Device PCB: Advanced sensor integration for pressure monitoring, accelerometer-based movement tracking, and temperature sensing

- Electric Toothbrush PCB: Wireless charging system design with inductive coupling optimization and foreign object detection

- Sonic Toothbrush PCB: High-frequency motor drive circuits with precise frequency control and harmonic filtering

SMT assembly lines are configured for miniature component placement, integrating microcontrollers, motor drivers, wireless modules, and precision timing circuits. Our turnkey assembly services for Electric Toothbrush PCB include firmware programming, motor calibration, waterproof testing, and comprehensive quality validation including drop tests, moisture resistance verification, and long-term battery performance evaluation.

Power Management and Battery Life Optimization

Electric Toothbrush PCB and Sonic Toothbrush PCB designs require sophisticated power management to maximize battery life while supporting high-performance motor operation and smart features:

- Smart Toothbrush PCB: Advanced power scaling algorithms that adjust motor intensity based on brushing mode and battery level

- Oral Care PCB: Ultra-low standby power consumption designs achieving less than 0.05 watts during wireless charging standby

- Rechargeable Toothbrush PCB: Intelligent charging circuits with overcharge protection and battery health monitoring using high-Tg PCB materials for enhanced thermal stability during charging cycles

- Dental Device PCB: Dynamic power management for sensor arrays and wireless communication modules

- Electric Toothbrush PCB: Multi-cell battery pack management with individual cell balancing and safety monitoring

- Advanced sleep mode functionality extending standby time to several months between uses

- Flex PCB interconnect solutions for ergonomic handle designs and space-constrained battery compartments

Sonic Toothbrush PCB designs require precise frequency control and harmonic management to achieve optimal cleaning performance while minimizing power consumption. High-frequency motor control often benefits from high-frequency PCB materials to ensure clean signal transmission and reduced electromagnetic interference with wireless communication systems.

Comprehensive Oral Care Device Ecosystem

Beyond core Electric Toothbrush PCB manufacturing, we provide integrated oral health technology solutions:

Motor Control and Vibration Systems:

- High-frequency sonic motor controllers for Smart Toothbrush PCB applications with precise frequency and amplitude control

- Ultrasonic piezoelectric drivers for advanced cleaning technologies

- Variable intensity control systems for sensitive teeth and gum care applications

- Multi-axis vibration patterns for enhanced plaque removal and gum stimulation

Smart Connectivity and User Interface:

- Bluetooth Low Energy modules for Oral Care PCB smartphone app integration utilizing rigid-flex PCB technology for compact antenna placement and reliable connection flexibility

- Pressure sensor arrays for real-time brushing technique feedback

- LED indicator systems for battery status, mode selection, and user guidance

- Haptic feedback controllers for intuitive user interaction

Charging and Power Systems:

- Wireless charging station circuits with foreign object detection and thermal protection

- Travel case power management for portable charging solutions

- USB-C charging interfaces with fast charging capabilities

- Solar charging integration for eco-friendly power solutions

Why Choose HILPCB for Electric Toothbrush PCB Manufacturing

At HILPCB, we understand that oral care device manufacturers need more than just a PCB supplier—they need a partner who can deliver innovation, reliability, and regulatory compliance for consumer safety. That's why we provide end-to-end solutions covering Electric Toothbrush PCBs, charging station electronics, motor control systems, and smart sensor integration, all produced with medical device quality standards and tested for waterproof performance, electromagnetic compatibility, and long-term durability. Our ISO 9001:2015 and IPC-A-610 Class 3 certifications, combined with specialized experience in consumer electronics and personal care devices, guarantee that every board meets the stringent requirements of daily-use oral health products.

Beyond manufacturing, we help our clients navigate the unique challenges of personal care device development—achieving optimal power efficiency, ensuring waterproof reliability, meeting regulatory safety standards, and integrating smart features that enhance user experience. From rapid prototyping to high-volume production, we manage component sourcing optimized for consumer electronics applications, precision assembly with cosmetic quality requirements, comprehensive testing including water immersion and electromagnetic compatibility validation, and full regulatory compliance support. This specialized approach ensures that your oral care devices—whether basic Rechargeable Toothbrush PCB systems or advanced Smart Toothbrush PCB platforms—achieve market success and exceed consumer expectations for performance and reliability.