The microwave spectrum from 1 GHz to 100 GHz has become the backbone of modern wireless communications, radar systems, and satellite technologies. High-frequency PCBs operating in these bands enable everything from 5G smartphones to autonomous vehicle radar and global satellite internet. These applications demand exceptional high-frequency PCB performance with precise impedance control, minimal loss, and reliable operation across extreme environmental conditions.

Our expertise spans the complete range of microwave applications, from sub-6 GHz cellular infrastructure to W-band automotive radar at 77 GHz, providing optimized solutions that balance performance, manufacturability, and cost for each unique application.

5G Infrastructure and Telecommunications Applications

The global rollout of 5G networks represents the largest deployment of microwave PCB technology in history. From massive MIMO base stations to small cell deployments, 5G infrastructure demands unprecedented performance across multiple frequency bands.

1. Sub-6 GHz 5G Base Station Requirements

Sub-6 GHz 5G operates in bands from 3.3-4.2 GHz and 4.4-5.0 GHz, requiring PCBs that balance performance with commercial viability. Base station designs incorporate 32-64 antenna elements for beamforming, demanding precise phase and amplitude matching across all channels. Our multilayer PCB solutions utilize hybrid stackups combining Rogers RO4350B for RF layers with standard FR4 for digital processing, optimizing cost while maintaining insertion loss below 0.5 dB per inch.

Power amplifier boards for base stations dissipate 100-200W, requiring sophisticated thermal management. We implement thick copper planes (3-4 oz), thermal vias arrays, and embedded coin technology to maintain junction temperatures below 85°C. Advanced materials like Rogers TC350 provide thermal conductivity exceeding 3.5 W/m·K while maintaining stable RF properties.

2. mmWave 5G Deployment Challenges

Millimeter-wave 5G at 28 GHz and 39 GHz presents unique PCB challenges. At these frequencies, standard FR4 exhibits unacceptable losses exceeding 2 dB/inch. We utilize ultra-low-loss materials including Rogers RO3003 (Df=0.0013) and Taconic RF-35 for mmWave applications. Surface roughness becomes critical—standard electrodeposited copper adds 0.5-1.0 dB/inch at 28 GHz. Our designs specify rolled copper or very-low-profile (VLP) copper with Rz <0.5μm.

Antenna-in-package (AiP) solutions integrate patch antenna arrays directly on the PCB substrate. Maintaining ±2% dielectric constant tolerance ensures consistent antenna dimensions and beam patterns. We achieve ±0.5 dB amplitude and ±5° phase matching across 256-element arrays through precise process control and 100% testing.

3. Small Cell and Indoor Solutions

Small cell deployments require compact, cost-optimized designs operating across multiple bands. Our solutions integrate 4G/5G radios, GPS, and WiFi in footprints under 200mm², utilizing HDI PCB technology with microvias and buried vias for maximum density. Blind via structures eliminate stubs at high-frequency transitions, maintaining return loss better than -20 dB through 6 GHz.

Automotive Radar Systems for ADAS and Autonomous Driving

Automotive radar at 24 GHz and 77 GHz enables advanced driver assistance systems (ADAS) critical for vehicle safety and autonomous operation. These systems must operate reliably from -40°C to +150°C while surviving vibration, moisture, and electromagnetic interference.

77 GHz Radar Design Considerations

The 77 GHz band offers superior resolution for automotive radar but demands exceptional PCB performance. At these frequencies, wavelength in typical substrates measures only 2-3mm, making every geometric feature critical. Our designs maintain:

- Phase matching: <5° across receive channels for accurate angle determination

- Amplitude balance: <0.5 dB ensuring consistent detection sensitivity

- Isolation: >40 dB between transmit and receive preventing self-interference

- Temperature stability: TCDk <50 ppm/°C maintaining calibration

Material selection focuses on Rogers RO3003G2 specifically developed for automotive radar. The ceramic-filled PTFE composite provides Dk=3.00±0.04 and Df=0.0013 with exceptional temperature stability. Glass transition temperature exceeding 280°C ensures reliability during lead-free assembly.

MIMO Radar Arrays and Beamforming

Modern automotive radar employs multiple-input multiple-output (MIMO) configurations with virtual apertures exceeding 100 channels. PCB designs integrate:

- Series-fed patch arrays for transmit beamforming

- Corporate feed networks ensuring equal phase to all elements

- Wilkinson dividers providing isolation between channels

- Substrate integrated waveguide (SIW) for low-loss distribution

Manufacturing tolerances become critical—±25μm registration errors cause 10° phase shifts at 77 GHz. Our process control maintains registration within ±12μm using laser direct imaging and automated optical inspection.

Environmental Reliability for Automotive

Automotive applications demand 15-year reliability under harsh conditions. Our qualification testing includes:

- Thermal cycling: -40°C to +150°C, 1000 cycles

- Thermal shock: 30-second transitions

- Humidity: 85°C/85% RH for 1000 hours

- Vibration: Random profile to 50G

- Salt spray: 96 hours exposure

Conformal coating and underfill protect against moisture while maintaining RF performance. Selective coating keeps antenna areas clear, preserving radiation patterns.

Satellite Communication Systems

Satellite communications span from L-band (1-2 GHz) for mobile services to Ka-band (26-40 GHz) for broadband internet. Each band presents unique challenges for PCB design and manufacturing.

Low Earth Orbit (LEO) Constellation Requirements

LEO constellations like Starlink and OneWeb require mass-producible user terminals with phased array antennas. Key requirements include:

- Circular polarization with axial ratio <3 dB

- Scan angles ±60° from broadside

- G/T ratio >10 dB/K for link closure

- Cost target <$500 per terminal

Our solutions employ multi-layer organic substrates with embedded phase shifters and low-noise amplifiers. Sequential lamination enables 16-layer constructions with blind and buried vias optimizing routing density. Total thickness remains below 2.4mm for weight constraints.

High-Throughput Satellite (HTS) Ground Stations

HTS ground stations operating at Ka-band and above require exceptional phase stability and low loss. PCB challenges include:

- Insertion loss <0.2 dB per inch at 30 GHz

- Phase stability <2° over temperature

- Power handling >100W for uplink amplifiers

- Multipaction resistance in vacuum

We utilize space-qualified materials including Rogers RT/duroid 6002 with demonstrated heritage. Hermetic via filling prevents outgassing while maintaining thermal conductivity. Gold plating provides corrosion resistance and reliable wire bonding for chip-and-wire assembly.

Defense and Aerospace Microwave Systems

Military applications push microwave PCB technology to its limits with requirements for operation from HF through W-band, often in extreme environments.

Electronic Warfare and Radar Systems

Electronic warfare systems require instantaneous bandwidth exceeding 20 GHz with consistent performance. Our solutions address:

Ultra-Wideband Challenges:

- Dispersion management maintaining group delay variation <100ps

- Mode suppression preventing higher-order propagation

- Broadband impedance matching from 2-18 GHz

- Isolation >60 dB between channels

Material selection balances electrical and mechanical requirements. Rogers CLTE-XT provides matched CTE to copper, preventing stress-induced failures during thermal cycling. The woven glass reinforced PTFE maintains mechanical stability for large format boards exceeding 600mm.

Phased Array Radar Implementation

Modern phased arrays integrate thousands of transmit/receive modules requiring precise corporate feed networks. Key design elements:

- Equal path lengths to ±1mm across 1024 elements

- Wilkinson combiner networks with integrated resistors

- DC bias distribution through RF paths

- Thermal management for >10kW dissipation

Rigid-flex PCB technology enables conformal arrays matching aircraft surfaces while maintaining phase coherence.

Emerging Microwave Applications

6G Research and Development

6G research explores frequencies from 100-300 GHz for terabit wireless links. PCB challenges at these frequencies include:

- Wavelengths approaching 1mm in-substrate

- Surface roughness effects dominating losses

- Tolerance requirements ±5μm for resonant structures

- Novel transmission lines (substrate integrated waveguide)

We're developing capabilities using liquid crystal polymer (LCP) and ultra-smooth copper for sub-THz applications.

Wireless Power Transfer

Microwave wireless power transfer for IoT and remote sensors operates at 2.45, 5.8, and 24 GHz ISM bands. PCB requirements include:

- High-Q resonators for rectenna efficiency

- Harmonic termination preventing re-radiation

- Thermal management for rectifier diodes

- Integration with energy storage

Our designs achieve 70% RF-to-DC conversion efficiency through optimized matching networks and Class-F rectifier topologies.

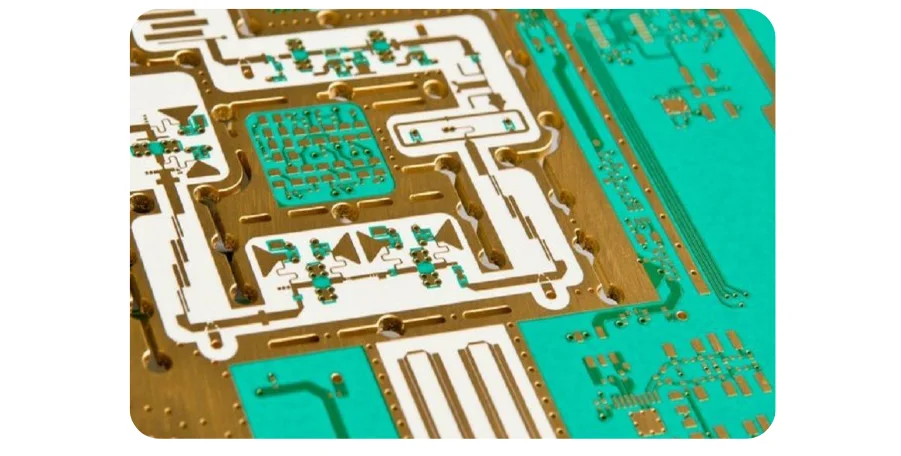

Key Design Considerations for Microwave Applications of High-frequency PCBs

Designing high-frequency PCBs for microwave applications requires careful consideration of materials, signal integrity, and thermal management. Microwave PCBs operate at frequencies from 1 GHz to 100 GHz, which means standard PCB materials and designs aren’t always sufficient.

Material Selection for Microwave PCB Applications

Selecting the right material is crucial for ensuring that microwave PCBs perform reliably across a wide frequency range. Key considerations include the dielectric constant (Dk), loss tangent (Df), and the material’s stability over temperature variations.

- Sub-6 GHz: Materials such as RO4350B and FR408HR offer a balance of cost and performance for lower-frequency microwave applications.

- 6-20 GHz: RO4003C and RO3003 are ideal for higher frequencies, offering low loss and stable dielectric properties.

- 20-40 GHz: RO3003 and RT5880 provide ultra-low loss with smooth copper surfaces, minimizing signal degradation at these high frequencies.

- Above 40 GHz: For mmWave applications, materials like RT5880LZ and LCP (Liquid Crystal Polymer) offer minimal loss and precise tolerances.

Optimizing Transmission Lines for Microwave PCB Design

Microwave signals require tightly controlled impedance and efficient transmission paths to maintain signal integrity. There are several ways to optimize transmission lines for high-frequency PCBs:

- Microstrip Design: The trace width is optimized to maintain a 50Ω impedance, and the ground plane spacing should be more than three times the trace width to minimize reflection and signal loss.

- Stripline Design: A balanced construction between ground planes ensures a stable transmission line with minimal interference.

- Coplanar Waveguide: This design is ideal for high-frequency signals, with controlled gap dimensions and ground plane stitching to prevent undesirable modes.

Grounding and Shielding for Microwave PCBs

Effective grounding and shielding are essential to prevent electromagnetic interference (EMI) and ensure stable operation in microwave applications.

- Star Grounding: For mixed-signal systems, a star grounding method minimizes noise coupling by providing a clean return path for signals.

- Continuous Ground Planes: A continuous ground plane beneath the RF section helps maintain signal integrity by ensuring a consistent return path.

- Shielding: We recommend compartment shielding between different functional blocks to isolate sensitive components and prevent cross-interference.

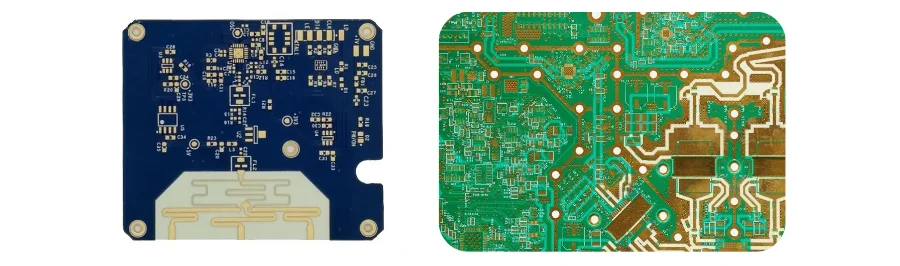

Why Choose Us for Microwave PCB Manufacturing and Assembly

When it comes to Microwave PCB manufacturing and assembly, HILPCB stands out as your trusted partner, offering expertise and solutions designed to meet the rigorous demands of high-frequency applications. Whether you are developing for 5G infrastructure, automotive radar, or satellite communication systems, we ensure that your designs perform optimally across the most challenging microwave applications.

Proven Expertise in Microwave PCB Design and Assembly

Our Microwave PCB solutions are tailored to meet the specific needs of industries that require superior performance across high-frequency bands. From sub-6 GHz to mmWave (up to 100 GHz), our experience covers a wide range of microwave applications of high-frequency PCBs that are crucial for next-generation technologies, such as 5G, autonomous driving, and satellite communications.

Comprehensive Solutions for Demanding Microwave Applications

We provide turnkey PCB assembly services that integrate packaging with PCB manufacturing, ensuring seamless design-to-production execution. This integrated approach ensures consistent impedance matching, optimal thermal management, and reliable signal integrity throughout the signal chain, addressing the challenges faced in microwave applications of high-frequency PCBs. Our team works with you to deliver efficient, cost-effective solutions without compromising on quality.

High-Quality Standards and Advanced Testing

Our process is backed by industry-leading quality certifications including ISO 9001, IPC-A-610, and J-STD-001, ensuring that every PCB meets the highest reliability standards. We perform rigorous testing for every board, including S-parameter measurements, time domain reflectometry (TDR), and environmental stress screening to ensure performance in demanding environments.

Why HILPCB is the Best Choice

- Tailored Microwave PCB Solutions: We specialize in high-frequency designs from sub-6 GHz for 5G infrastructure to mmWave for advanced applications like automotive radar and satellite communications.

- Expert Design & Assembly: With HDI PCB technology, multi-layer designs, and high-precision via technology, we ensure your PCBs meet strict performance and reliability requirements.

- Complete Customization: From material selection to stack-up optimization, we offer fully customized solutions tailored to your specific microwave application needs.

Choosing HILPCB means you’re partnering with a team of experts committed to ensuring your microwave PCBs meet the most demanding standards, offering you reliable, high-performance solutions for critical applications.

Contact us today to learn more about our Microwave PCB manufacturing and assembly services, and how we can support your microwave applications of high-frequency PCBs.